Geocell Driveway

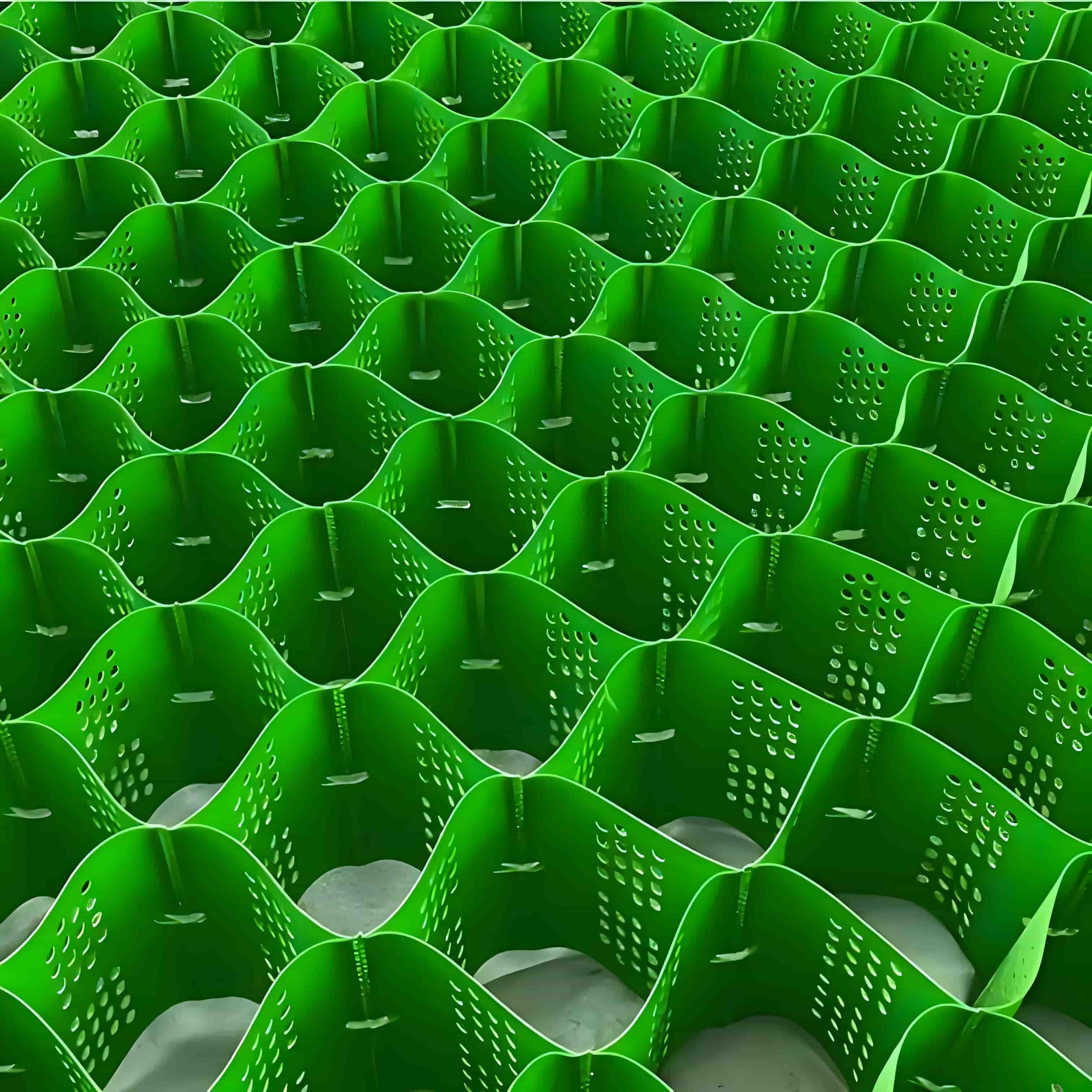

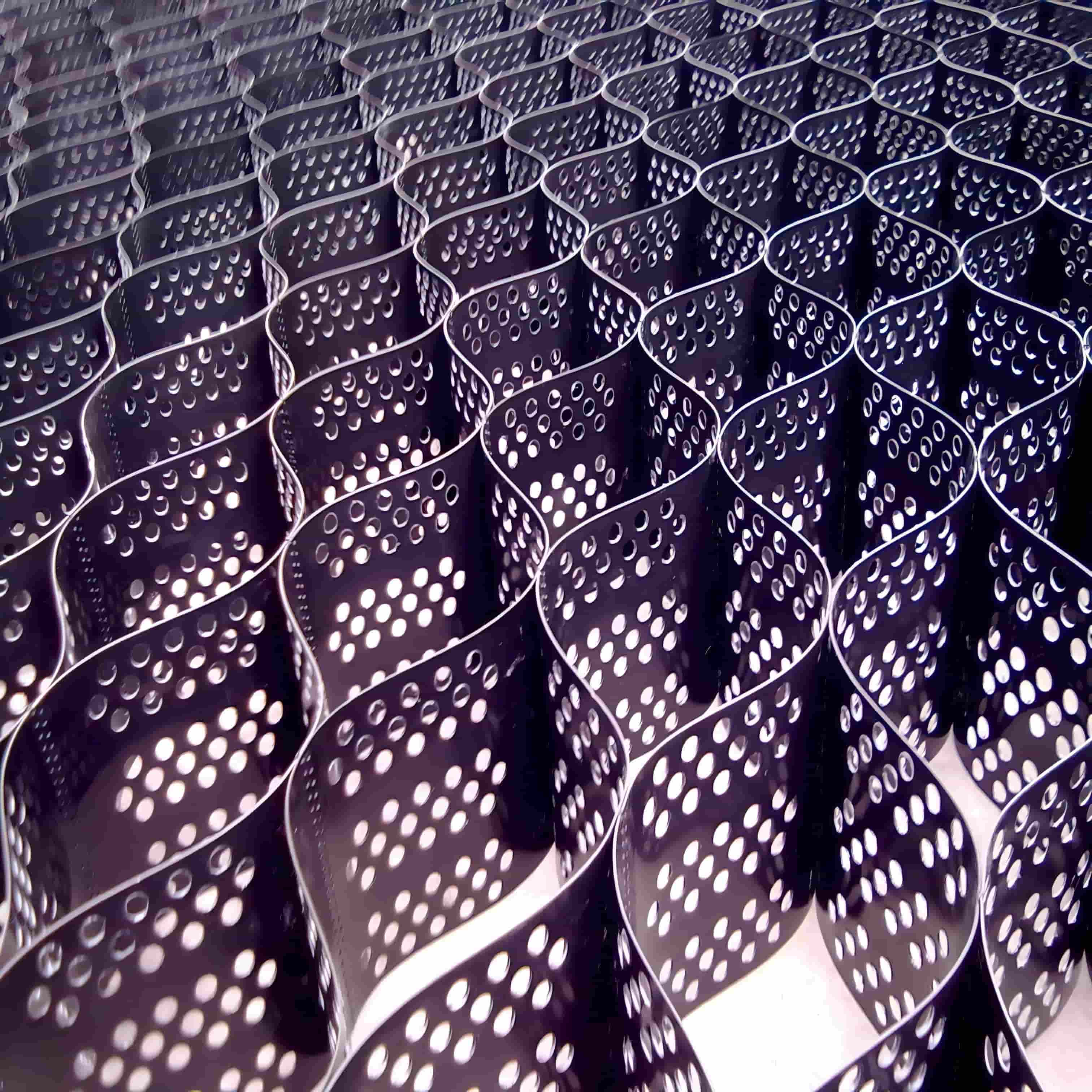

Geocell is a three-dimensional honeycomb-shaped engineering material, formed by ultrasonic welding of high-density polyethylene (HDPE) or polypropylene (PP), and it has core advantages such as high strength, flexible ductility and rapid construction. Its honeycomb units can efficiently restrain filling materials (such as sand, gravel, and soil), significantly enhancing the bearing capacity and anti-erosion performance of the foundation. They are widely used in slope protection, soft foundation treatment, and ecological restoration projects. They comply with the ISO 9001 quality management system and green infrastructure standards, and are an innovative solution in the field of civil engineering.

Geocell is a three-dimensional, honeycomb-like engineering material made from high-density polyethylene (HDPE) or polypropylene (PP) through ultrasonic welding. It offers key advantages such as high strength, excellent flexibility, and fast installation.

I. Structure and Material Properties

Honeycomb cell design

1. Geocell Unit size: 100mm×100mm to 400mm×400mm (customizable), height 50 to 300mm;

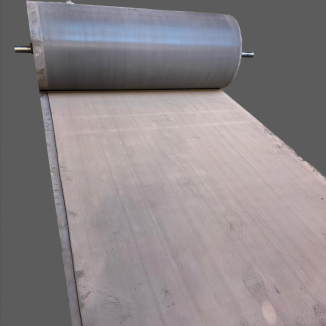

2. Expansion rate: 1:5 to 1:10 (folding transportation, quick on-site expansion), saving 90% of storage and transportation space.

High-strength material

1.HDPE material: Tensile strength ≥25MPa, low-temperature resistance (applicable from -50℃ to 80℃), UV aging resistance (strength retention ≥90% after 2000 hours of UV).

2. Node strength: The anti-peeling force of the welding points is ≥500N/cm, ensuring the long-term stability of the structure.

Water permeability and air permeability

The opening rate of the honeycomb side wall is ≥15%, which promotes drainage and ventilation and prevents soil softening caused by water accumulation.

Specifications

| No. | Raw materials | |||||||

| Test Item | Unit | Polyethylene | Polypropylene | Polystyrene | ||||

| Extrusion Type | Tensile Type | Extrusion Type | Tensile Type | Extrusion Type | Tensile Type | |||

| 1 | Tensile Strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

| 2 | Tensile Creep Strain | % | ≤15 | — | ≤15 | — | ≤15 | — |

| 3 | Tensile Fracture Strain | % | — | 8~20 | — | 6~15 | — | 8~20 |

| 4 | Carbon Black Contenta | % | — | — | — | — | 2.0~3.0 | — |

| 5 | Carbon Black Dispersiona | — | — | No more than 1 out of 10 samples rated Level 3; Levels 4 and 5 not allowed | ||||

| 6 | 200°C Oxidation Induction Time | min | ≥20 | ≥20 | — | |||

| 7 | Time to Failure under Tensile Stress Cracking | h | ≥300 | — | ||||

| 8 | Retention Rate after Accelerated Weatheringb | % | ≥80 | |||||

| 9 | Retention of Physical-Chemical Propertiesc | % | ≥80 | |||||

Ii. Function and Engineering Advantages

Foundation reinforcement and bearing strengthening

1. Constrain the lateral displacement of filling materials, increase the bearing capacity of the foundation by 50% to 200%, and is suitable for scenarios such as weak foundations and railway subgrades.

2. It has a remarkable ability to resist uneven settlement, which can reduce the frequency of roadbed repair.

Anti-scouring and slope protection

1. The honeycomb structure disperses the impact force of water flow, reducing the slope erosion rate by ≥70%, and is suitable for projects such as river slope protection and mine restoration.

2. Vegetation can grow through the compartments, achieving a synergistic effect of "engineering reinforcement + ecological greening".

Convenient construction and cost optimization

1. Modular assembly design, with a single-person daily laying area of 500 to 800 square meters.

2. No large-scale machinery is required, and the comprehensive cost is 40% lower than that of traditional concrete structures.

Iii. Core Application Fields

Transportation infrastructure

1. Highway/railway subgrade: Soft foundation reinforcement, subgrade stability in permafrost areas;

2. Airport runway: Prevent reflective cracks on the runway surface and enhance the bearing capacity of the base layer.

Water conservancy and environmental protection engineering

1. River slope protection: Resisting water flow erosion and promoting vegetation recovery;

2. Mine restoration: Surface solidification of tailings ponds, slope protection of quarries;

3. Landfill: Reinforcement of the closure cover layer.

Ecology and Municipal Engineering

1. Roof greening: Lightweight base structure, supporting planting soil and vegetation;

2. Sponge City: Rain garden, permeable pavement base reinforcement;

3. Temporary roads: Rapid laying of passage layers in marshes and desert areas.

Iv. Environmental Protection and Certification

Sustainable materials

1. It adopts 100% recyclable HDPE raw materials, and the production energy consumption is reduced by 60% compared with concrete.

2. The discarded compartments can be recycled and comply with the EU RoHS environmental protection standards.

Authoritative certification

1. China Ten-Ring Certification, ASTM D7864 (Tensile Strength Test)

2. Passed the international standards ISO 13426 (node strength) and ISO 12958 (water permeability).

Summary

Geocells, with three-dimensional constraints and efficient load-bearing as their core values, achieve the dual goals of engineering reinforcement and ecological protection through the combination of scientific structures and high-strength materials. Its wide range of application scenarios (from transportation infrastructure to sponge cities) and significant economic benefits (saving construction period and material costs) make it an innovative material in the modern engineering field. In the future, it will be expanded to emerging fields such as base surface protection of photovoltaic power stations and coastline restoration, contributing to global sustainable development.