Geotextile 60m2

1.Strong filtration and drainage: Separate soil and water to prevent blockage, accelerate drainage and protect the foundation.

2.Durable and wear resistant: Acid and alkali resistant, aging resistant, long-term pressure resistant.

3.Time saving construction: Lightweight and easy to cut, fast laying for small and medium-sized projects.

4.Wide scene adaptation: It integrates reinforcement, isolation and protection, and is universal for road and garden foundations.

Product Introduction

1、 Basic attributes

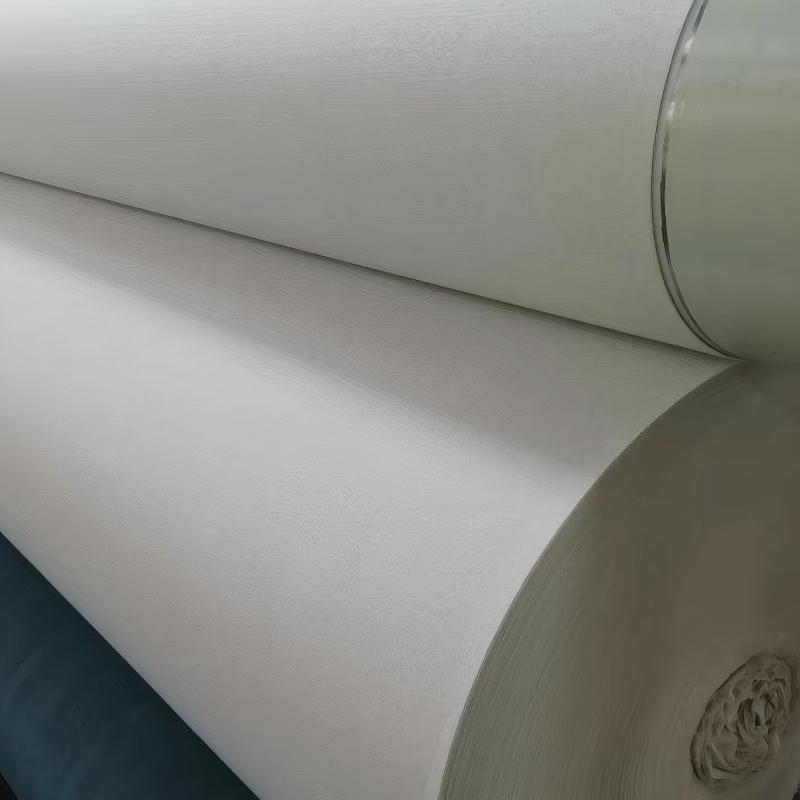

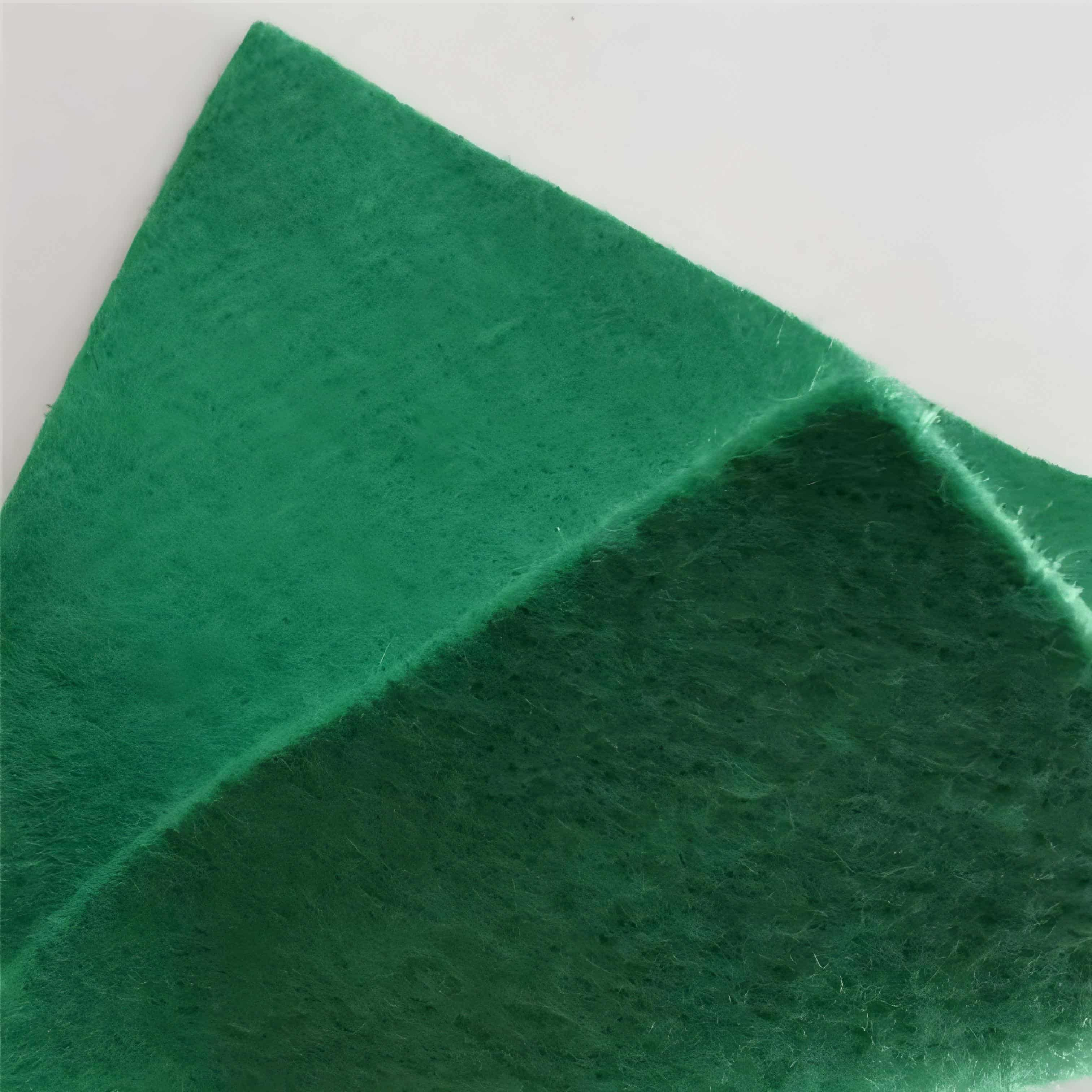

Geotextile 60m2 are usually produced using high molecular weight synthetic fibers such as polypropylene and polyester as raw materials. Taking the needle punching process as an example, the fibers that have been combed into a net are laid out in a disorderly and flat manner. Through repeated punctures with barbed needles, the fibers are entangled with each other, forming a cloth like structure with a certain thickness and strength; The weaving process uses machines to interweave fiber yarns into warp and weft, creating a more regular and compact fabric surface.

A geotextile with an area of 60 square meters has a relatively light overall weight, depending on the weight per square meter (commonly 100-1000 g/square meter), making it convenient for transportation and on-site handling. In terms of flexibility, it can easily adapt to construction needs such as bending and folding, as well as laying with terrain undulations, demonstrating good plasticity.

In terms of chemical stability, polypropylene and polyester have stable chemical properties themselves. In acidic and alkaline environments, whether in strongly acidic industrial wastewater areas or highly alkaline saline alkali engineering scenarios, geotextiles can resist chemical erosion for a long time without significant performance degradation. At the same time, after special anti ultraviolet treatment, it can withstand long-term sunlight exposure in outdoor engineering, effectively delaying aging and brittleness caused by ultraviolet radiation and ensuring its service life.

2、 Core functions

Filter drainage: Geotextiles have a precise and uniform fiber pore structure. When water infiltrates from fine-grained soil layers to coarse-grained soil layers, these pores can act as a "sieve", allowing water to pass smoothly while firmly intercepting soil particles, fine sand, small stones, etc., preventing them from migrating with water flow, thus preventing soil erosion and maintaining the stability of soil and water engineering. Moreover, within the soil, geotextiles can quickly collect excess water and guide it in an orderly manner towards the drainage system. For example, laying geotextiles around dams, riverbank slopes, and underground drainage pipelines can efficiently divert accumulated water and avoid problems such as softening and collapse of the engineering foundation caused by water immersion.

Reinforcement protection: Geotextiles have high tensile strength and can significantly enhance the bearing capacity of soil structures when combined with soil. For example, in road subgrade construction, laying geotextile between soil layers is like adding a "tendon network" to the soil. The external pressure generated by vehicle movement is dispersed through the geotextile, reducing local stress concentration and effectively reducing the possibility of subgrade settlement; In slope protection engineering, geotextile is closely attached to the soil, enhancing the anti sliding ability of the soil, reducing the risk of landslides, and protecting the safety of buildings and facilities around the slope.

3、 Main features

Convenient construction: The specific specification of 60 square meters can be considered "tailor-made" for small and medium-sized projects. In the transportation process, due to its light weight, ordinary trucks can easily carry without the need for large and professional transportation equipment. After arriving at the construction site, the construction personnel can use conventional cutting tools such as scissors and knives to flexibly cut the geotextile into suitable shapes according to the actual construction terrain and size requirements. When laying, due to its soft material, it can closely fit various complex terrains, including uneven ground, curved slopes, etc., greatly improving construction efficiency and saving a lot of time.

Durable and economical: In terms of tear resistance, the synthetic fibers used in geotextiles have high strength and are tightly bonded through special processing techniques. When pulled by external forces, fibers can work together to resist tearing, and are not easily damaged even under harsh conditions such as long-term soil pressure and mechanical friction. In terms of aging resistance, in addition to the anti-aging properties of raw materials, anti-aging additives will be added in the production process to further improve its durability in the natural environment. This long-life characteristic means that the replacement frequency of geotextiles is reduced throughout the entire project life cycle. In the long run, it greatly reduces maintenance costs and combines durability and economy.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1、 Road engineering field

In the construction of small and medium-sized roads such as rural roads and park access roads, 60 square meters of geotextile can be laid between the roadbed soil layers. Its fiber structure can effectively isolate soils of different particle sizes, avoiding loose structures caused by the mixing of base sand and roadbed clay. At the same time, by dispersing vehicle loads, it reduces roadbed settlement and extends the service life of roads. In addition, in road slope protection, laying geotextiles can prevent soil erosion caused by rainwater erosion and enhance slope stability.

2、 Water conservancy and drainage engineering

In scenarios such as small dams, irrigation channels, and courtyard drainage systems, 60 square meters of geotextile plays a crucial role in filtration and drainage. When laid on the upstream face of the dam or at the bottom of the channel, it can not only intercept sediment and impurities in the water body, prevent channel blockage, but also quickly divert seepage water, reduce the water pressure load of the dam and channel, and avoid structural damage caused by waterlogging.

3、 Landscape and infrastructure renovation

In the construction of garden landscapes (such as artificial lakes and flower beds) or the renovation of old sites, 60 square meters of geotextile is an ideal isolation and protection material. Laying between planting soil and gravel layer can prevent soil particles from infiltrating into the drainage layer and causing blockage; Laying before ground hardening can reduce direct contact between concrete and base soil, lower the risk of ground cracking caused by soil settlement, and especially meet the local renovation needs of small and medium-sized sites.

4、 Building foundation and landfill engineering

For local anti-seepage of small building foundation treatment or landfill sites, 60 ㎡ geotextile can be used in combination with other materials. In the reinforcement of soft soil foundation, geotextiles enhance the tensile strength of the soil and improve the bearing capacity of the foundation; When laying around the landfill site, it can isolate the garbage from the surrounding soil, prevent the infiltration and diffusion of pollutants, and assist in the drainage of leachate, ensuring the environmental protection of the project.

60 ㎡ geotextile, with its core functions of isolation, filtration, reinforcement, and drainage, has demonstrated efficient adaptability in various types of projects such as small and medium-sized roads, water conservancy, gardens, and building foundations. Its flexible specifications and convenient construction characteristics can not only solve practical problems such as soil mixing, settlement, and erosion, but also adapt to local engineering needs, providing key support for the structural stability and durability of various small and medium-sized projects.