Geotextile Anti Contaminant

1. Double anti fouling is more thorough: it has both physical barrier and chemical adsorption capabilities, with a barrier rate of over 98% to intercept heavy metals and chemical pollutants. Some models can also adsorb trace pollutants, comprehensively blocking the spread of pollution.

2. Long service life of weather resistance and corrosion resistance: acid and alkali resistance, UV resistance, stable use in environments ranging from -30 ℃ to 80 ℃, with a normal service life of 10-20 years. Long term exposure to pollutants is also not easy to damage or degrade.

3. Performance customization and wide adaptability: Water permeability and breathability can be customized according to needs, suitable for irregular site laying, and adaptable to multiple scenarios such as industrial restoration, landfill, and farmland protection, with no usage limitations.

4. Environmentally friendly, non-toxic, and free of secondary pollution: It does not contain harmful substances, has zero pollution release during production and use, and some models can be degraded or recycled. It can also ensure environmental safety when used in ecologically sensitive areas.

Products Introduction:

Geotextile Anti Contaminant is a functional geosynthetic material designed specifically for blocking and adsorbing pollutants. It is made of polypropylene (PP) and polyester (PET) as base fabrics, and is coated (such as PVC and HDPE film layers), composite (combined with activated carbon and nano adsorbent materials), or modified to give the material a dual anti pollution ability of "physical barrier+chemical adsorption". Its core function is to build a protective barrier between soil, water and pollutants, which can prevent the infiltration and diffusion of harmful substances such as heavy metal ions, chemical pollutants, oil pollution, etc., and actively adsorb some pollutants to avoid their pollution of soil, groundwater or surrounding ecological environment. This product does not require complex construction equipment and is suitable for industrial site restoration, landfill, chemical tank area protection and other scenarios. It is a key material for achieving pollution isolation and ecological protection in environmental engineering.

Product Features:

1. Dual anti fouling and barrier adsorption: After special treatment, the base fabric forms a physical barrier through a high-density film layer or dense fabric structure, with a barrier rate of over 98% against heavy metals (such as lead, cadmium, mercury) and chemical organic compounds (such as benzene and phenols), preventing pollutant infiltration and diffusion; On the other hand, some types of composite activated carbon, zeolite and other adsorption materials can actively adsorb trace pollutants in water or soil, with an adsorption capacity of up to 5% -15% of their own weight, further reducing pollution risks.

2. Corrosion resistance, aging resistance and strong durability: the base cloth is made of acid and alkali resistant and corrosion resistant polymer materials, and the coating or composite layer is treated with UV resistance and aging resistance, which can withstand the chemical erosion of industrial sites, outdoor strong sunshine and temperature changes (-30 ℃ to 80 ℃). Under normal operating conditions, the service life can reach 10-20 years, and long-term exposure to pollutants is not easy to degrade or damage, ensuring stable anti pollution effects.

3. Controllable permeability and breathability, suitable for multiple scenarios: Different permeability and breathability properties can be customized according to application needs - such as the anti fouling geotextile used in landfills, which adopts a low permeability design to prevent infiltration of leachate; Products for farmland soil remediation scenarios retain moderate breathability to ensure soil microbial activity. At the same time, the material has good flexibility and can be laid in irregular areas (such as uneven ground in industrial sites and curved foundations in storage tank areas) without wrinkles or hollowing.

4. Environmentally friendly and non-toxic, with good ecological compatibility: The product itself does not contain harmful substances such as heavy metals and formaldehyde, and there is no pollutant release during production and use; After retirement, it can be professionally recycled or naturally degraded under specific conditions (some bio modified models) without causing secondary pollution to the environment. When used in ecologically sensitive areas such as water source areas and farmland soil remediation, it can ensure the safety of the living environment for animals and plants.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

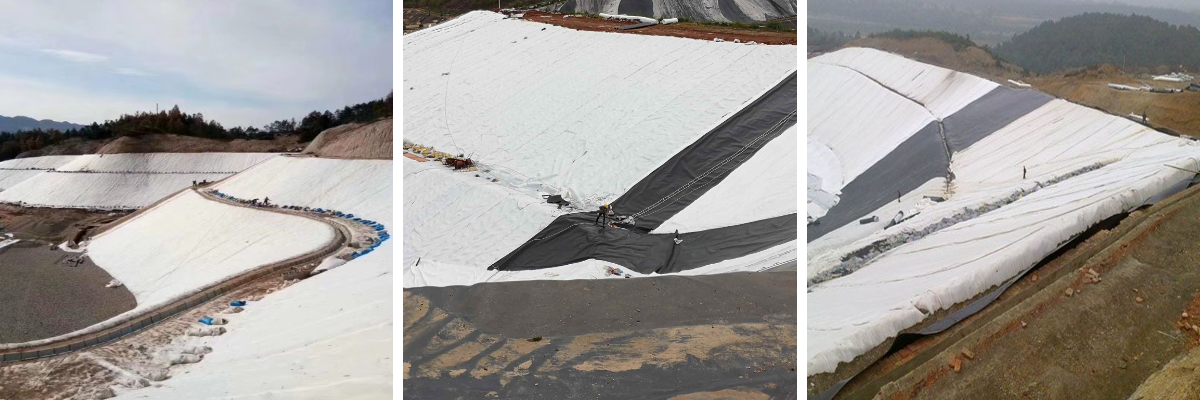

1. Industrial site remediation project: In the remediation of polluted sites such as chemical plants, smelters, electroplating plants, etc., a barrier is laid between polluted soil and uncontaminated soil to prevent heavy metals and chemical pollutants from infiltrating deep soil and groundwater; Simultaneously adsorbing residual pollutants, assisting soil leaching, bioremediation and other technologies to improve remediation efficiency.

2. Landfill protection: As the "secondary anti-seepage layer" of the landfill, it is laid under the main anti-seepage membrane or in the surrounding buffer zone to prevent the landfill leachate from polluting the soil and groundwater after breaking through the main anti-seepage layer; At the same time, it can cover the surrounding area of the landfill gas collection pipe, reducing the diffusion of pollutants with the landfill gas and ensuring the ecological safety of the landfill site.

3. Chemical storage tank area and oil depot protection: Anti pollution geotextile is laid in the ground and underground foundations of chemical storage tanks and finished oil depots to form a circular protective zone. When a storage tank leaks, it can block the infiltration of oil and chemical raw materials, avoid soil and groundwater pollution, and facilitate the collection and cleaning of subsequent leaks.

4. Protection of farmland and water sources: In the treatment of agricultural non-point source pollution (such as soil pollution caused by excessive fertilizers and pesticides), it is laid under the cultivated layer of farmland to prevent pollutants from infiltrating into groundwater; The ecological buffer zone around the drinking water source is used to isolate pollutants in surface runoff and ensure the safety of water quality in the water source area.

Geotextile Anti Contaminant takes "dual anti fouling, durability and stability, scene adaptation, and ecological protection" as its core advantages, accurately solving the pain points of "difficult pollutant barrier, weak long-term protection, and poor ecological compatibility" in environmental engineering. Whether it is the deep restoration of industrial sites, risk prevention and control of landfills and chemical areas, or ecological protection of farmland and water sources, it can all build reliable pollution protection barriers through scientific performance design, which not only prevents the spread of pollutants but also reduces interference with the ecological environment. As the "ecological guardian" of environmental engineering, this product balances functionality and sustainability, providing an efficient and economical solution for promoting pollution control and ensuring ecological safety. It is an indispensable key material in modern environmental engineering.