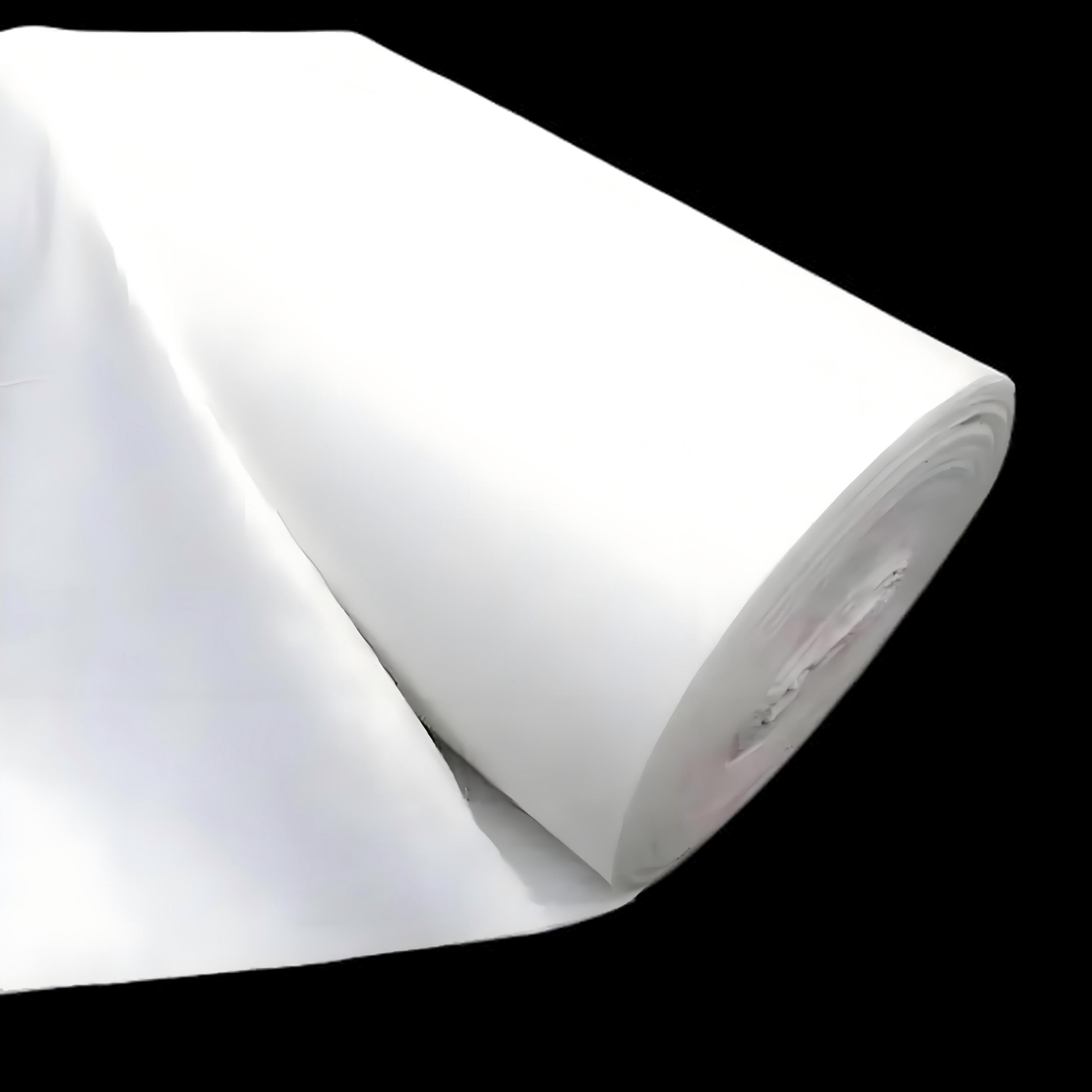

Geo Fabric Filter Cloth

1、Fully functional:Filtering, drainage, isolation, and reinforcement are all done in one step to meet the diverse needs of the project.

2、Environmental resistance:Synthetic fiber material, corrosion resistance, aging resistance, frost resistance, stable use in complex environment.

3、Cost saving:Simple construction saves time, extends project lifespan, and reduces maintenance expenses.

4、 Ensure safety:Drainage pressure reduction, reinforcement to stabilize the structure, and prevention of hidden dangers such as collapse and settlement.

Product Introduction

1、 Basic concepts and classifications

Basic concepts

Geo Fabric Filter Cloth is a permeable geosynthetic material made from synthetic fibers (such as polypropylene, polyester, nylon, etc.) through processes such as needle punching, weaving, weaving, and hot melting. It has high tensile strength, good permeability, and corrosion resistance, and can play a stable role in complex environments for a long time. It is one of the most widely used categories in geosynthetic materials.

Main categories

According to the manufacturing process and structural characteristics, geotextile filter cloth can be divided into the following categories:

Needle punched non-woven geotextile filter cloth: By using needle punching technology to wrap and fix fibers together to form a three-dimensional structure, it has the characteristics of high porosity, good permeability, and strong flexibility, and is suitable for most filtration scenarios.

Woven geotextile filter cloth: made by interweaving warp and weft yarns, with stable structure and high tensile strength, but relatively low permeability, commonly used in filtration projects with high strength requirements.

Woven geotextile filter cloth: produced using traditional weaving techniques, with a flat fabric surface, good dimensional stability, and high filtration accuracy, suitable for scenarios with strict filtration requirements.

Composite geotextile filter cloth: made by combining two or more processes (such as needle punching+weaving), it combines the advantages of different materials and can meet complex engineering needs.

2、 Core functions and operating principles

Core functions

Filtering function: allows water or other liquids to pass through while blocking solid impurities such as soil particles and sand, preventing blockages in pipelines, drainage ditches, and other facilities.

Drainage function: Collecting and discharging water through its own porous structure, reducing the pore water pressure in the soil, and avoiding damage to the structure due to water accumulation.

Isolation function: Separate materials of different particle sizes (such as soil and sand, sand and stone) to prevent material mixing and maintain structural stability.

Reinforcement function: Enhance the tensile strength and deformation resistance of soil, and improve the bearing capacity of structures such as slopes and roadbeds.

Protective function: Protect soil or other structures from external forces such as water flow erosion and wind erosion.

Working principle

The implementation of filtration and drainage depends on the pore structure of geotextile filter cloth: its pore size needs to be between water molecules and filtered particles, which can allow water to pass smoothly and intercept particles. At the same time, the permeability of the material ensures that moisture can flow along the fabric surface or internal channels and be discharged.

The isolation function is achieved through the mechanical stability of the material: the geotextile filter cloth itself has a certain strength and stiffness, which can block the mutual penetration of different materials and maintain structural layering.

The reinforcement function utilizes the tensile properties of the material: when the soil deforms under stress, the geotextile filter cloth can share some of the tension, limit the displacement of the soil, and enhance the stability of the overall structure.

Product Parameters

| C | metric | ||||||||||

| Nominal strength/(kN/m) | |||||||||||

| 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

| 1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

| 2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

| 3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

| 4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

| 5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

| 7 | Width deviation rate /% ≥ | -0.5 | |||||||||

| 8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

| 9 | Thickness deviation rate /% ≥ | -10 | |||||||||

| 10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

| 11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

| 12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

| 13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

| 14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1、 Water conservancy engineering

Dam construction: laid between the dam body and foundation, as well as inside the dam body, to filter seepage and prevent soil particle loss, discharge accumulated water to reduce pore water pressure, and prevent dam body seepage and collapse.

Channel engineering: laid on the slope and bottom to resist water erosion and reduce soil erosion, drain and keep the surrounding soil dry, and extend the service life of the channel.

Reservoir engineering: used for bank protection and dam drainage to ensure safe storage and operation of the reservoir.

2、 Transportation Engineering

Highway and railway subgrade: laid between the filling material and the foundation to isolate and prevent material mixing; Softening of drainage and waterproofing subgrade, strengthening of tensile strength to enhance bearing capacity, reducing settlement and cracking.

Tunnel engineering: As a drainage layer between the initial support and secondary lining, it collects and discharges seepage from the surrounding rock, preventing seepage from affecting structural safety and driving environment.

3、 Environmental Protection Engineering

Landfill site: A anti-seepage filter layer is laid at the bottom and periphery to filter the leachate and prevent pollutants from penetrating the soil and groundwater.

Wastewater treatment plant: used for sludge filtration, sedimentation tank filtration, separation of solid impurities in sewage, improving treatment efficiency and ensuring water quality.

4、 Municipal Engineering

Underground drainage pipeline: A filtering layer is installed at the entrance or around the pipeline to remove sediment and debris, prevent blockages, and ensure smooth drainage.

Pedestrian walkways and squares: After installation, enhance ground drainage to avoid water accumulation during rainy days that may affect traffic.

River regulation: used for shore protection construction, filtering water impurities and resisting water flow erosion, maintaining river ecology and landscape.

5、 Mining Engineering

Slag storage yard: isolate slag from surrounding soil, prevent harmful substances from spreading and polluting, and reduce environmental impact through filtration and drainage.

Tailings dam construction: used for dam drainage and seepage prevention, reducing dam pressure by draining accumulated water, preventing dam collapse and other safety accidents.

The application of geotextile filter cloth in many fields such as water conservancy, transportation, environmental protection, municipal engineering, mining, etc. is of irreplaceable importance. In hydraulic engineering, it is the "invisible guardian" that safeguards the safety of dams, channels, and reservoirs, effectively resisting the risks of infiltration and erosion; In transportation engineering, it lays a solid foundation for the stability of roadbeds and tunnels, reducing road surface diseases and safety hazards; In environmental engineering, it is a key barrier for pollution prevention and control, helping to safeguard the ecological security of soil and water resources; In municipal engineering, it makes urban drainage more smooth and the environment more livable; In mining engineering, it provides a solid guarantee for slag treatment and tailings dam safety. Its diverse functions not only ensure the structural safety and stable operation of various projects, but also play a profound role in environmental protection, extending project life, and reducing later maintenance costs. Reasonable selection and scientific application of geotextile filter cloth is an important measure to improve the quality of engineering construction and achieve sustainable development of engineering. It has significant practical significance and long-term value in promoting the efficient, safe, and environmentally friendly development of engineering construction in various industries.