Dredge Dewatering Bags

Choosing geo baggage for your dredging operations offers a couple of technical, economic, and environmental benefits:

Cost-Efficiency: Significantly reduces disposal and transport costs with the aid of the use of dewatering sediments on-site, minimizing volume.

Environmental Compliance: Effectively consists of contaminants, prevents sediment runoff, and meets stringent water satisfactory standards.

Versatility & Adaptability: Suitable for a large range of materials—from outstanding silt to sandy sediments—and adaptable to extra than a few website conditions.

Space-Saving Solution: Allows for confined dewatering and storage, nice for initiatives with restricted land availability.

Erosion Control & Land Reclamation: Stabilized dredged material inside baggage can be used beneficially for shoreline protection, embankments, or land creation.

Reduced Carbon Footprint: Minimizes trucking and off-site disposal, decreasing gasoline consumption and general mission emissions.

Products Introduction:

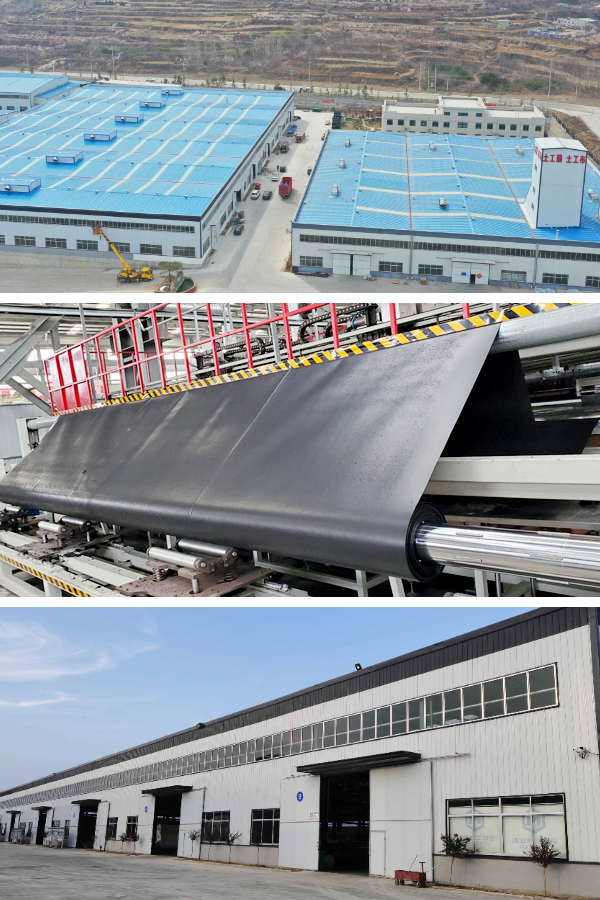

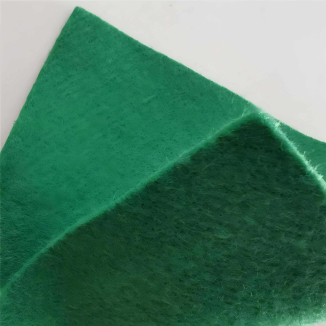

Geo bags for dredging, moreover recognized as geotextile containers or sediment bags, are engineered cloth containers used for dewatering, containing, and stabilizing dredged materials. Made from high-strength, permeable geotextiles, these baggage are designed to efficiently separate water from sediments like silt, sand, and sludge at some factor of dredging operations. As environmental insurance policies tighten and sustainable practices flip out to be a priority, geo bags grant a practical, cost-effective, and environmentally in charge reply for managing dredged spoils in ports, harbors, rivers, and coastal projects.

Product Features:

Our geo baggage are manufactured to meet the nerve-racking conditions of dredging and dewatering projects:

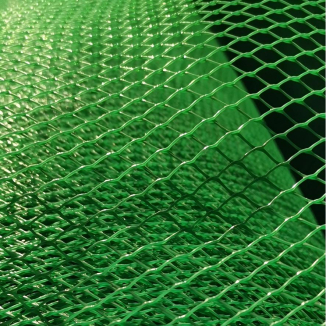

High-Strength Woven Geotextile Fabric: UV-resistant, lengthy lasting polypropylene fabric withstands abrasion, puncture, and tensile stresses for the period of filling and placement.

Controlled Permeability: Precisely engineered pore sizes allow quick dewatering at the same time as preserving first-class particles, making sure clear effluent water.

Customizable Sizes & Capacities: Available in pretty a variety dimensions—from small baggage to massive containers preserving hundreds of cubic meters—to go nicely with project-specific needs.

Easy Deployment & Installation: Lightweight when empty, common to transport, and can be stuffed in situ the use of stylish dredging equipment.

Integrity & Durability: Designed to maintain structural steadiness below load and over time, even in dynamic marine or aquatic environments.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

Geo bags are a versatile reply employed during severa marine, civil, and environmental projects:

Port & Harbor Maintenance: Dewatering of contaminated sediments all via activities dredging to preserve navigational depths.

River & Canal Restoration: Sediment containment and stabilization in waterway rehabilitation projects.

Coastal Protection & Beach Nourishment: Using dewatered sand for dune reinforcement or seaside fill applications.

Contaminated Sediment Remediation: Isolating and solidifying polluted sludge for safe, contained disposal or treatment.

Land Reclamation & Fill Projects: Creating stable, contained foundations the utilization of dredged fabric in aquatic environments.

Emergency Spill & Silt Control: Rapid deployment as silt curtains or barriers to manipulate sediment plumes in the route of dredging.

Conclusion

Geo baggage for dredging signify a smart, sustainable desire for present day sediment management. By combining efficiency, compliance, and versatility, they handle every operational and environmental challenges head-on. Whether you’re managing a large-scale harbor dredge, a river cleanup, or a coastal protection project, integrating geo baggage can streamline operations, minimize costs, and limit ecological impact.

Ready to optimize your dredging mission with reliable geo bag solutions? Contact our crew these days for expert consultation, personalized specifications, and high-performance geotextile merchandise tailored to your needs.