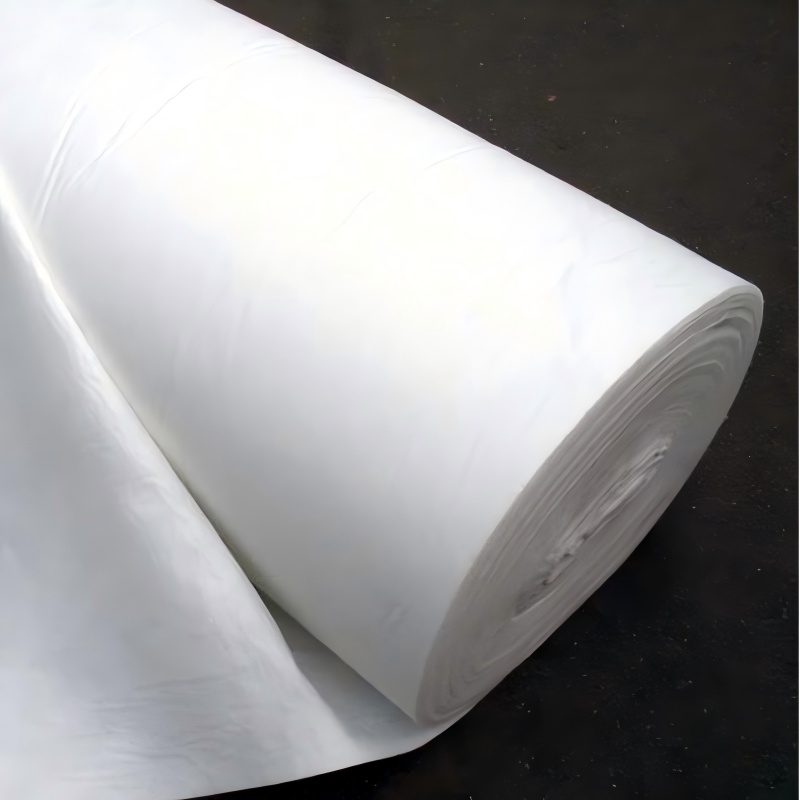

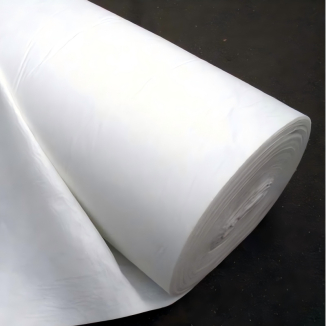

Geo Drainage Fabric

1.Efficient drainage:The porous structure can quickly drain accumulated water, reduce pore water pressure, and prevent instability.

2.Reinforced and load-bearing:Transmitting force constrained deformation to enhance the anti settlement and sliding ability of foundation slopes.

3.Isolation and energy protection:Separate different materials to prevent mixing and ensure the functional stability of the structural layer.

4.Convenient weather resistance:Lightweight, tough, easy to construct, corrosion-resistant, durable, cost-effective, suitable for complex scenarios.

Product Introduction

1、 Basic attribute: Building performance foundation

Geo Drainage Fabric is based on a porous network structure and lightweight and flexible properties as its core physical foundation. The continuous channels formed between fibers provide natural conditions for efficient water infiltration, enabling rapid water flow within the soil; It exhibits outstanding chemical stability and can withstand acid and alkali erosion, microbial corrosion, and UV aging in soil. Even in special and harsh environments such as wetlands and saline alkali land, it can maintain its performance stability for a long time. In addition, its material has good ductility and plasticity, and can be precisely cut and spliced according to the size requirements of different projects. It can easily adapt to the construction requirements of complex terrains such as steep slopes and depressions, providing a basic guarantee for the development of the project.

2、 Core function: Directly addressing engineering challenges

Drainage and seepage control: With the dense micro pore channels inside the fabric, it can quickly absorb and discharge surface water, groundwater, and seepage generated during construction, effectively reducing soil pore water pressure. In road engineering, it can effectively avoid softening problems caused by accumulated water on the road; In dam engineering, it can reduce the risk of piping and prevent engineering hazards such as structural instability from the root.

Reinforcement enhancement: By transmitting friction and tension with the soil, local loads are evenly distributed over a larger area, effectively constraining soil deformation. When laid on weak foundations, it can significantly improve the bearing capacity of the foundation; When used for slope protection, it can enhance the anti slip ability of soil, reduce the occurrence of settlement, collapse and other situations, and ensure the stability of engineering structures.

Isolation and protection: By utilizing the barrier properties of different materials, precise separation of materials with different particle sizes such as soil and sand, sand and stone is achieved, preventing materials from mixing under water flow erosion or external forces. Laying between the roadbed and the cushion layer can ensure that the drainage function of the cushion layer is not blocked by fine soil; In river regulation, it can isolate soil and water bodies, reduce soil erosion and structural damage, and maintain the functional integrity of each structural layer of the project.

3、 Main feature: Enhance the comprehensive value of the project

In the construction process, geotextile drainage fabrics exhibit convenient and efficient characteristics, without the need for complex mechanical assistance, and can be manually laid, greatly shortening the construction period and reducing disturbance and damage to the construction site, especially suitable for engineering construction in ecologically sensitive areas. Moreover, it has excellent weather resistance and anti-aging performance, which can ensure that the materials can maintain a stable working state during long-term use, reduce the frequency of maintenance and replacement in the later period, and thus significantly reduce the maintenance cost of the whole life cycle of the project. The dual advantages of functionality and economy make it an indispensable key material for improving engineering quality in many fields such as water conservancy, transportation, and municipal engineering.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1、 Water conservancy engineering field

Geotechnical drainage fabric is the core auxiliary material in projects such as dams, channels, and river regulation. In dam construction, laying it on the outer side of the anti-seepage layer of the dam body or at the dam foundation can quickly discharge the seepage water above the seepage line of the dam body, reduce the pore water pressure, and prevent dangerous situations such as piping and landslides; In channel engineering, it is laid at the bottom and slope of the channel, which can not only discharge soil seepage to reduce channel leakage, but also isolate the soil from the lining material, avoiding fine soil particles from blocking the lining gaps; When using ecological bags or gabion nets for river ecological management, it can enhance the stability of the bank slope and reduce the erosion of the embankment by water flow through drainage function.

2、 Transportation engineering field

Geotechnical drainage fabrics play a crucial role in the construction of roads, railways, and airport runways. During the roadbed construction phase, it is laid at the bottom of the roadbed or between the base layer and the cushion layer, which can discharge rainwater and groundwater from the roadbed soil, prevent roadbed softening and settlement, and extend the service life of the road; In the treatment of high fill subgrade or soft soil foundation, combining with crushed stone cushion layer to form drainage channels accelerates the consolidation of the foundation and improves the bearing capacity of the subgrade; In slope protection engineering, it is used in conjunction with anchor rods, grids, etc., to reduce the risk of slope soil slip and ensure road safety through the dual effects of reinforcement and drainage.

3、 Municipal engineering field

Municipal drainage, underground pipeline network, and building foundation engineering rely on their functional characteristics. In the construction of urban underground comprehensive pipe galleries, laying on the outside of the pipe gallery can form a drainage buffer layer to discharge the surrounding soil seepage and prevent the pipe gallery structure from being eroded by water pressure; In the underground drainage system of residential areas or municipal roads, as a filtering material wrapped around the drainage blind ditch, it can not only filter sediment to prevent blind ditch blockage, but also accelerate rainwater infiltration and discharge; When treating building foundations, it is used for drainage and consolidation of weak soil layers, shortening the stability period of foundation settlement and improving the safety of foundation bearing.

4、 Environmental Protection and Ecological Engineering Field

Widely used in projects such as landfills and artificial wetlands. In the anti-seepage system of a landfill site, geotextile drainage fabric is laid above the anti-seepage membrane to collect leachate and discharge it to the treatment system, while protecting the anti-seepage membrane from sharp object punctures; In the construction of artificial wetlands, they are laid at the bottom and slopes of the wetland to isolate different substrate layers, prevent soil and filling materials from mixing, and ensure the internal water circulation of the wetland and a breathable environment for plant roots; In mining reclamation projects, it is used to repair drainage and soil reinforcement in the area, assisting in ecological restoration and soil and water conservation.

Geotechnical drainage fabrics play an irreplaceable role in various fields such as water conservancy, transportation, municipal engineering, environmental protection, and ecology, thanks to their core functions of drainage, reinforcement, and isolation. It can not only solve practical problems such as water accumulation, settlement, and material mixing in engineering, but also adapt to complex scenarios, reduce maintenance costs, and provide key support for the structural stability and long-term operation of various projects.