Commercial Geotextile Fabric

1. Improving engineering quality: By using functions such as isolation, reinforcement, and filtration, the stability and bearing capacity of structures such as roadbeds and dams are significantly improved, reducing uneven settlement.

2. Extend the service life of the project: effectively prevent the loss and mixing of base materials, slow down road frost heave, foundation subsidence and other diseases, thereby extending the service life of the project.

3. Enhance environmental adaptability: In difficult site conditions such as soft soil foundation and steep slopes, it can effectively solve technical problems and expand the scope of construction.

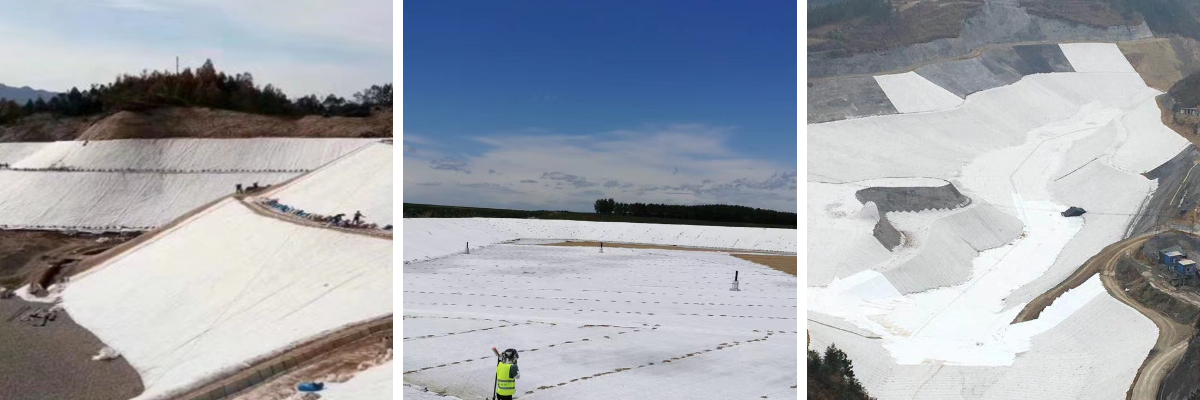

4. Beneficial for environmental protection: By preventing soil erosion, it plays a role in soil and water conservation; In projects such as landfills, it can protect the anti-seepage layer and prevent the leakage of pollutants.

Product Introduction:

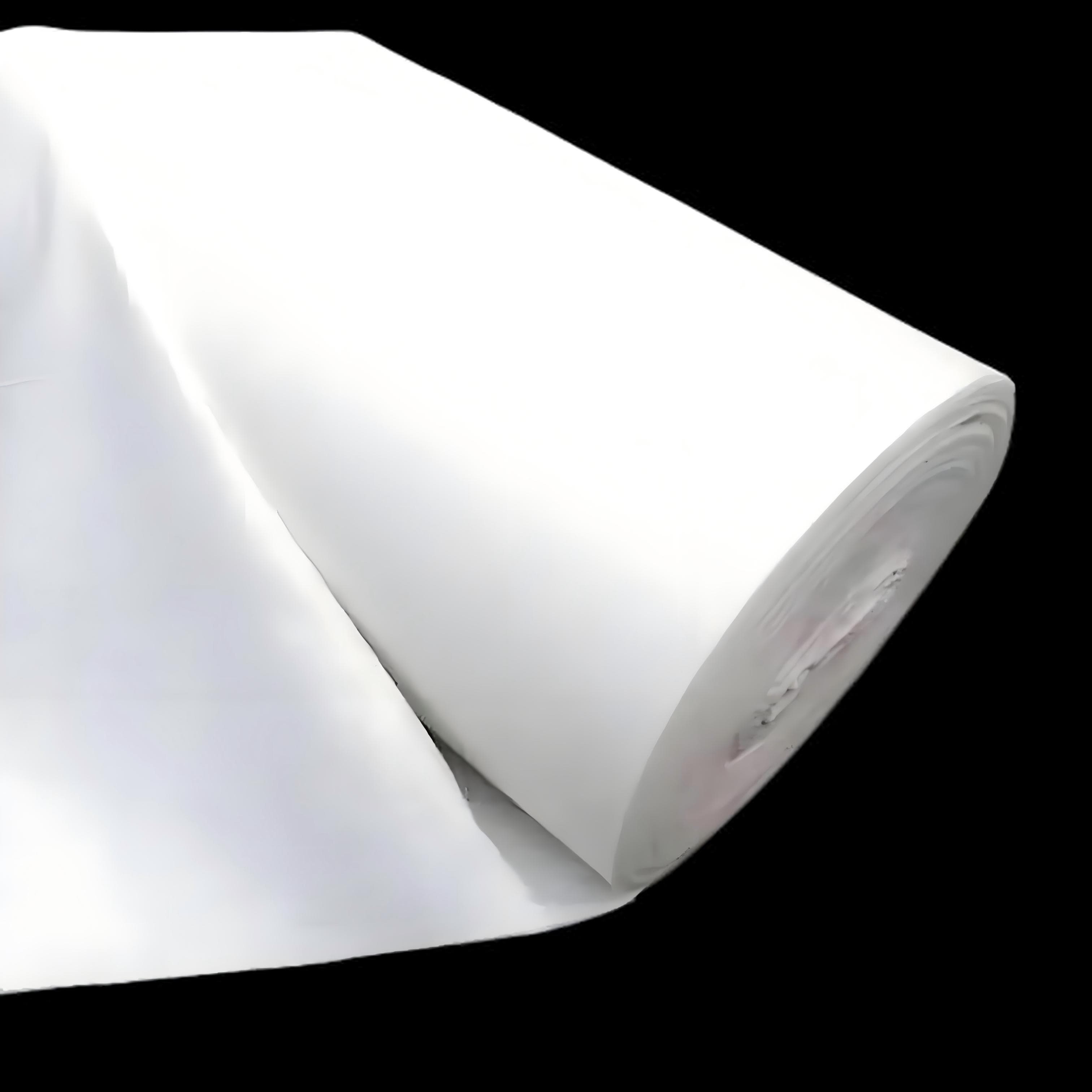

Commercial Geotextile Fabric, also known as industrial grade geotextile, refers to porous textile materials that meet industrial and engineering standards and are widely used in commercial construction projects. Its raw materials are mainly synthetic polymers (such as polypropylene PP, polyester PET, polyethylene PE, etc.), with a few natural fibers (such as flax, coconut shell fiber, etc., suitable for specific environmental protection scenarios). The final product is formed through processes such as spinning, needle punching, weaving, thermal bonding or chemical bonding, and exhibits the characteristics of being breathable, permeable but impermeable to solid particles. It can work synergistically with engineering materials such as soil, rock, sand and gravel to solve problems such as foundation stability and soil and water conservation in engineering.

Main Features

The characteristics of commercial geotextiles revolve around the design of "engineering adaptability", which can be summarized into the following five points:

1. Strong physical stability: High tensile strength (balanced transverse and longitudinal strength, with some woven geotextiles having a tensile strength of over 50kN/m), outstanding tear and puncture resistance, able to withstand rolling, pulling, and soil self weight pressure during construction, and not easily deformed or damaged.

2. Excellent chemical resistance: It has good resistance to acid and alkali (stable within the pH range of 3-11), salt spray, industrial pollutants, and microbial erosion. It can be used for a long time in soil, groundwater, or outdoor environments (usually designed for a lifespan of 10-50 years), and is not easily aged, corroded, or degraded (unless it is a specially designed "degradable geotextile").

3. Permeability and filtration balance: It has a reasonable pore structure (porosity is usually 60% -90%), which can quickly remove excess water from the soil (permeability can reach 10-300 L/(m ² · s)), and also intercept soil particles to prevent soil erosion or sand layer mixing, maintaining the layered stability of the engineering structure.

4. High construction convenience: The products are mostly packaged in roll form (2-6 meters wide, 50-100 meters long), lightweight (usually 100-800g per square meter), and can be cut and spliced according to engineering needs. There is no need for complex equipment during installation, and they can adapt to complex terrains such as slopes and curved surfaces, greatly reducing the construction period.

5. Balancing environmental protection and economy: Synthetic geotextiles have a wide range of raw materials and low energy consumption in the production process; Some products can be recycled and reused, in line with the concept of green engineering; At the same time, it can reduce the dependence of the project on traditional materials such as sand and cement, and lower long-term maintenance costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Transportation infrastructure

Road engineering: laid between the roadbed and the base layer, isolating sand and gravel materials of different particle sizes to prevent the roadbed soil from mixing into the base layer and causing structural looseness; At the same time, drain the accumulated water on the roadbed to avoid frost heave or overturning, and improve the road's bearing capacity.

Railway engineering: used under the track bed to filter fine soil in the sand and gravel of the track bed, prevent track bed compaction, and ensure track elasticity; Simultaneously isolate the roadbed and track bed to reduce roadbed settlement.

Airport runway: As an isolation layer between the base layer and the cushion layer, it enhances the stability of the runway base layer and resists the impact load caused by aircraft takeoff and landing.

2. Water conservancy and waterway engineering

Embankment/Flood Control Embankment: Geotextile is laid on the inner side to filter the soil of the embankment and prevent piping caused by seepage; The outer side can be combined with geomembrane to enhance the anti-seepage effect and protect the geomembrane from being punctured by sharp stones.

River management: laid on the slope of the river to prevent soil erosion caused by water flow, and combined with vegetation planting to form an ecological slope protection system of "geotextile+plant".

Port terminal: used for reinforcing the foundation of the yard, isolating the fill soil from the foundation soil, accelerating the drainage and consolidation of the foundation, and reducing the settlement of the yard.

3. Construction and Municipal Engineering

Building construction: The basement floor or outer wall is laid as a drainage filter layer to prevent soil particles from blocking the drainage holes and ensure the moisture-proof effect of the basement; It can also be used as a drainage layer for roof greening, filtering fine materials from planting soil.

Landfill site: laid at the bottom and slope of the landfill area as a protective layer for the anti-seepage membrane to prevent sharp objects in the garbage from piercing the anti-seepage membrane; At the same time, it serves as the filtration layer of the leachate collection system to avoid pipeline blockage.

Municipal pipeline network: used for the surrounding backfill layer of rainwater and sewage pipelines, isolating backfill soil from pipelines, reducing soil pressure on pipelines, and filtering rainwater to prevent pipeline siltation.

4. Environmental restoration and ecological engineering

Soil improvement: In the remediation of saline alkali land or polluted soil, geotextiles are laid to isolate the polluted layer from clean soil and prevent the spread of pollutants; Simultaneously cooperate with the drainage system to accelerate the leaching and discharge of soil salts or pollutants.

Mine reclamation: used for slope protection of abandoned mining land, fixing surface soil, and providing a stable foundation for vegetation restoration; Simultaneously filtering rainwater to reduce the infiltration of heavy metal ions in slag with rainwater.

Artificial wetland: As a layered isolation layer of wetland bed, it filters suspended solids in sewage, ensures the purification efficiency of wetland plants and microorganisms, and prevents soil erosion of the bed.

In summary, commercial geotextile, as an efficient, economical, and environmentally friendly engineering material, has solved many problems in traditional engineering through its multifunctionality (isolation, reinforcement, filtration, drainage, protection), and has become one of the key materials for improving engineering quality, saving costs, and achieving sustainable development in modern infrastructure construction.