Geo Fabric for Under Driveway

1. Anti sinking foundation: Enhance the overall integrity of the lane base, prevent soil subsidence, and avoid deformation and cracking of the asphalt layer

2. Filter and drain moisture: quickly drain rainwater, prevent water accumulation from softening the roadbed, and reduce muddy and bumpy lanes

3. Anti rolling and anti-wear: Resist long-term rolling and wear of vehicles, withstand outdoor environments, and extend the service life of lanes

4. Easy to lay and labor-saving: easy to cut and fit the ground, no need for large equipment, high construction efficiency, controllable cost

Products Introduction:

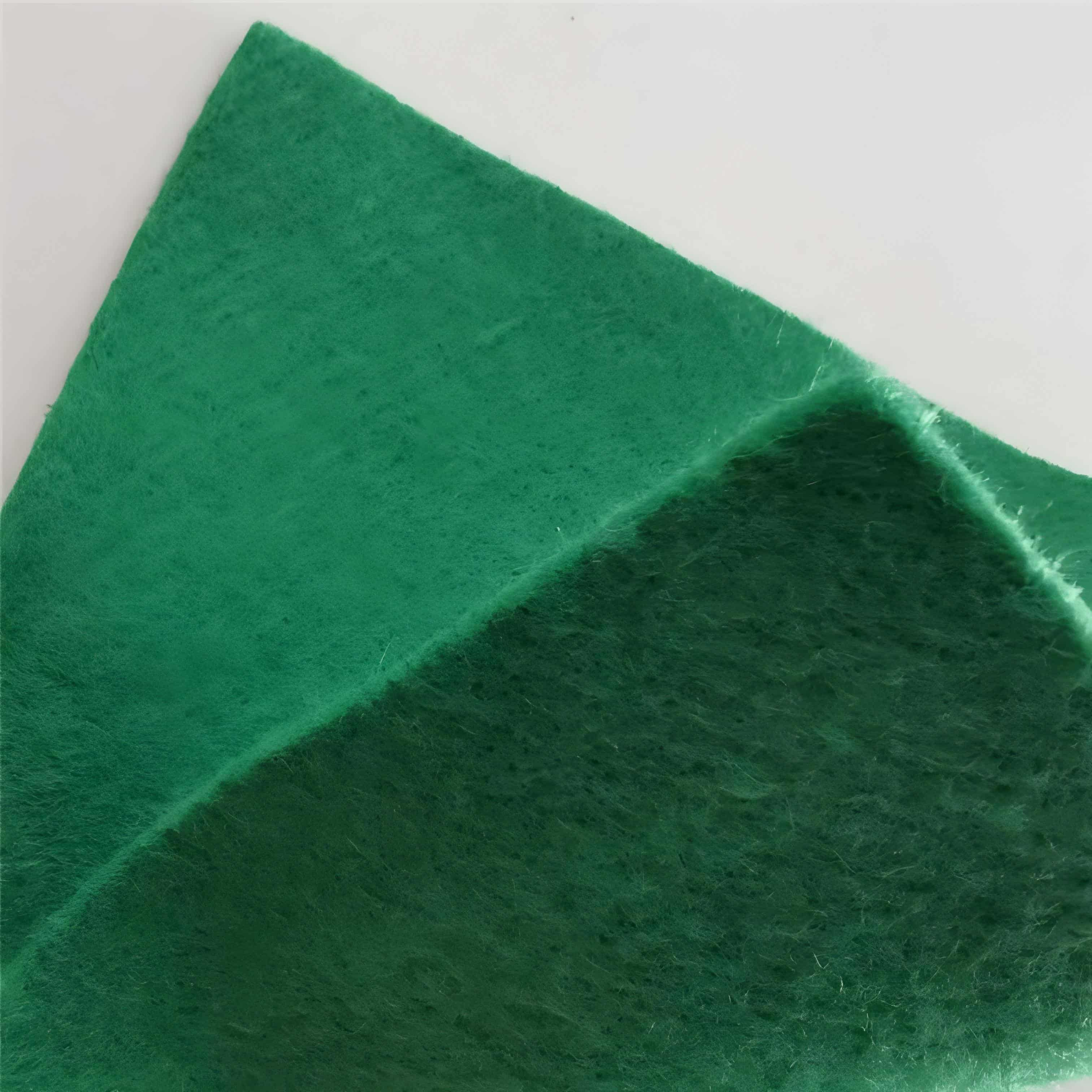

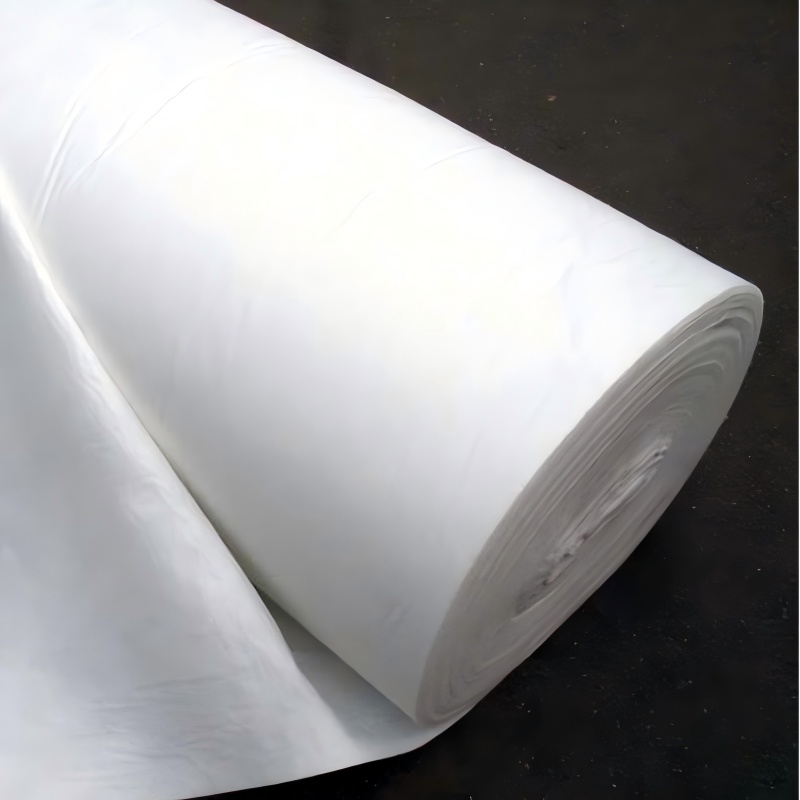

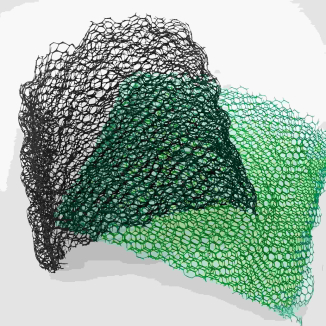

Geo Fabric for Under Driveway is a functional geotechnical material designed specifically for lane base layers. It is made of polypropylene (PP) or polyester (PET) as the core raw material, and is produced through needle punched non-woven, woven or composite processes. Its core positioning is "protection and stability barrier for lane base layers". It is laid between the gravel, asphalt or concrete surface layer and the soil base layer of the lane, and through the synergistic effect of physical isolation, reinforcement and drainage filtration, it solves the pain points of "base subsidence, surface cracking, and water damage" in the long-term use of the lane, providing long-lasting and stable base support for household lanes and small commercial lanes (such as garage entrances and exits, courtyard lanes), and extending the overall service life of the lane.

Different from general geotextiles, this product is designed for the scenario of frequent vehicle compaction and the need to resist rainwater erosion in lanes. It enhances tensile resistance, wear resistance, and drainage performance, and can be adapted to various types of lane surface layers such as asphalt, concrete, and gravel. It is a key material for replacing traditional sand and gravel cushion layers and reducing maintenance costs in modern lane construction.

Product Features:

1. Strengthen the base layer, prevent subsidence and deformation

Using high modulus fibers and dense weaving technology, the longitudinal and transverse fracture strength can reach 15-40kN/m, and the shear strength is 25% -35% higher than ordinary geotextiles. After laying, it can form a "composite stable layer" with soil and gravel, dispersing the local load generated by vehicle compaction (such as the conventional weight of cars and SUVs), preventing the soil base from sinking or sinking due to uneven stress, avoiding cracking and arching of the upper layer of gravel/asphalt/concrete surface layer, especially suitable for lane base scenarios such as soft soil and backfill soil that are prone to deformation.

2. Double optimization of filtration and drainage, preventing water accumulation and protecting the roadbed

The three-dimensional porous structure (porosity of 60% -75%) combines the functions of "filtration+drainage": on the one hand, it intercepts fine soil particles to prevent them from infiltrating the gravel layer with rainwater and causing blockage, maintaining the drainage and load-bearing performance of the gravel layer; On the other hand, it can quickly alleviate the surface water accumulation and soil seepage of the lane, with a permeability coefficient of ≥ 1 × 10 ⁻ cm/s, to avoid the retention of water and soften the soil base, reduce the mud, frost heave (winter) or surface layer peeling caused by water accumulation in the lane, and adapt to the lane demand in rainy and humid areas.

3. Resistant to rolling and damage, suitable for long-term use

After anti ultraviolet and anti-aging treatment, it can be used stably in outdoor sun and rain environment for 8-12 years; The surface fibers are tightly interwoven, with excellent wear resistance, able to resist friction during gravel paving and long-term vehicle crushing (without damage under conventional household vehicle loads), and can withstand extreme temperatures of -30 ℃ to 70 ℃. It does not crack in winter and does not soften in summer, avoiding protection failure caused by environmental aging and reducing the trouble of frequent lane maintenance.

4. Flexible and easy to lay, suitable for various lane scenes

Soft texture and good ductility (fracture elongation rate of 20% -40%), can fit the slight slope, edge corner or local depression of the lane, without blind spots for laying; Moderate weight (150-300g/m ²), light weight, easy cutting, no need for professional large equipment, 2-3 people can manually complete the laying (overlap width ≥ 10cm to ensure integrity), suitable for fast construction of small domestic lanes (such as 50-200 square meters), compatible with the laying process of gravel lanes, asphalt lanes, and concrete lanes.

5. Economic adaptation to reduce full cycle costs

Compared to traditional lane base solutions such as thickening gravel cushion layers and pouring concrete leveling layers, material costs are reduced by 20% -30%, construction efficiency is increased by 1-2 times (100-150 square meters can be laid in a single day), and the lane construction period is shortened; In long-term use, due to the improvement of grassroots stability, the maintenance cycle of the lane surface layer has been extended from 3-5 years to 8-10 years, reducing the manpower and material investment for later repairs, especially suitable for the demand of "low-cost and less maintenance" for household lanes.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Construction and renovation of domestic lanes

New gravel/asphalt lane: laid between the soil base layer and the gravel cushion layer to isolate the soil and gravel, prevent soil particles from blocking the gravel pores, and enhance the bearing capacity of the base layer to avoid vehicle crushing causing the gravel layer to sink and the lane to have potholes. Suitable for scenarios such as courtyard private lanes and villa garage entrance and exit lanes.

Renovation and repair of old lanes: In response to the problems of soft base and cracked surface layer of old lanes, after removing the damaged surface layer, the geotextile is laid on the original soil base layer, and then the crushed stone or asphalt surface layer is re laid. This can quickly restore the stability of the lane base layer, reduce renovation costs (without the need for deep excavation and reconstruction of the base layer), and is suitable for old household lanes that have been in use for more than 5 years.

2. Small commercial and functional lanes

Small lane in front of the shop: used as a temporary parking lane in front of convenience stores and small supermarkets (with a load of ≤ 5 tons), laid between the concrete surface layer and the soil base layer, to enhance the deformation resistance of the base layer, resist the cracking of the surface layer caused by frequent entry and exit of customer vehicles, and also to divert rainwater to avoid the accumulation of water in the front lane affecting customer traffic.

Community/Park Internal Lane: Suitable for small lanes connecting residential buildings and parking lots within the community, as well as light truck passages (with a load of ≤ 8 tons) within industrial parks. The base layer is reinforced with geotextile to reduce settlement caused by vehicle traffic, maintain lane flatness, and reduce post maintenance pressure on the property industry.

3. Lane adaptation for special scenarios

Wet/Rainy Area Lane: In rainy areas in the south or areas with high groundwater levels, laying this geotextile can accelerate the drainage of accumulated water from the lane base, prevent soil softening from causing lane sinking, and avoid muddy and difficult to drive lanes during rainy seasons. It is suitable for rainy rural and suburban lanes.

Soft soil/backfill soil base lane: For the backfill soil lane and soft soil area lane around newly built residential buildings, laying geotextile can enhance the overall integrity of the base, prevent backfill soil settlement and soft soil deformation, provide stable support for the upper surface layer, and avoid damage to the lane in the short term.

Geo Fabric for Under Driveway has the core advantages of "strengthening the base layer to prevent subsidence, filtering and draining accumulated water to protect the roadbed, being resistant to rolling and damage, having a long service life, and being easy to lay and maintain economically." It accurately solves the core pain points of "unstable base layer, susceptibility to water damage, and frequent maintenance" in lane construction and use, and is a "key material for base layer protection" for household and small commercial lanes.

Compared to traditional lane base solutions, this product not only reduces costs and improves efficiency during the construction phase, but also extends lane life and reduces maintenance troubles in long-term use. It perfectly adapts to the needs of "cost-effectiveness and convenience" in household scenarios, as well as the requirements of "stability and durability" in small commercial scenarios. Its widespread application not only promotes the development of lane construction towards "lightweight, low-cost, and long-life" direction, but also provides users with a more worry free and durable lane usage experience, making it an ideal choice for modern lane grassroots protection.