Geotextile Waterproofing

Highly effective waterproofing and anti-seepage: The dense fiber structure effectively blocks water penetration while allowing moisture inside the soil to escape, preventing structural damage caused by water accumulation. The waterproofing effect is long-lasting and stable.

Durable and aging-resistant: Resistant to acids, alkalis, UV rays, and microbial attack, it can withstand soil pressure and mechanical friction, boasting a service life far exceeding that of traditional waterproofing materials, reducing ongoing maintenance costs.

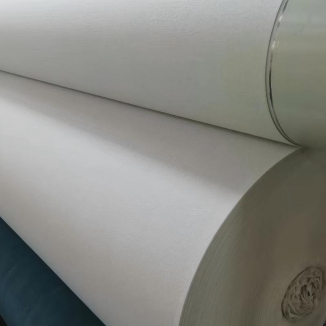

Easy and flexible construction: Lightweight and flexible, it can be cut and spliced to suit the construction scenario, adapting to complex terrain without the need for complex equipment, shortening the construction cycle.

Eco-friendly and economical: Utilizing primarily recyclable or environmentally friendly materials, it is pollution-free to the soil and ecosystem. Its filtration and reinforcement properties allow it to replace multiple materials, reducing overall project costs.

Product Introduction:

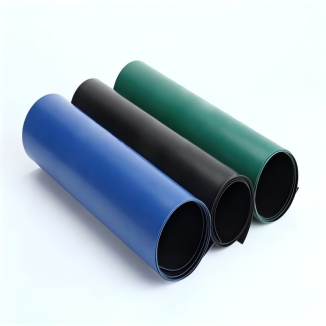

Geotextile waterproofing is a functional geotextile made from polymer synthetic fibers through processes such as needle punching, weaving, or hot-melt processing. Its compact fiber structure and special coating treatment achieve multiple functions: high-efficiency waterproofing, ecological compatibility, and durability and adaptability. It is a key material in modern engineering waterproofing.

This product breaks the limitations of traditional waterproofing materials, which are rigid, prone to cracking, and highly contaminating, by combining three core properties: First, it offers a precise balance between waterproofing and breathability. Its dense fibers block the penetration of liquids such as water and leachate, while allowing moisture from within the soil or structure to escape, preventing structural softening and mold caused by accumulated water. Second, it offers strong environmental adaptability, resisting acid and alkali corrosion, UV aging, and mechanical puncture (resisting friction from soil and gravel, and construction compaction), maintaining stable performance even in extreme temperatures and humidity. Third, it offers flexible adaptability and environmental friendliness. Its lightweight construction allows it to be cut and assembled to suit complex terrains, including embankments, tunnels, and basements. Its raw materials are mostly recyclable or contain no volatile chemicals, resulting in no ecological hazards to soil, water, or life, thus meeting green engineering standards.

From the perspective of application value, Geotextile Waterproofing can not only replace traditional waterproofing membranes, asphalt and other materials, reducing construction steps and subsequent maintenance costs, but also, through the combined functions of "waterproofing + reinforcement + filtration", simultaneously solve multiple needs such as engineering leakage, structural stability, and ecological protection. It has become the preferred waterproofing solution in the fields of water conservancy, transportation, construction, and environmental protection.

Product Parameters:

| project | metric | ||||||||||

| Nominal strength/(kN/m) | |||||||||||

| 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

| 1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

| 2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

| 3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

| 4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

| 5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

| 7 | Width deviation rate /% ≥ | -0.5 | |||||||||

| 8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

| 9 | Thickness deviation rate /% ≥ | -10 | |||||||||

| 10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

| 11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

| 12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

| 13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

| 14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water Conservancy and Hydropower Engineering: Core Solutions: "Seepage Control + Structural Stability"

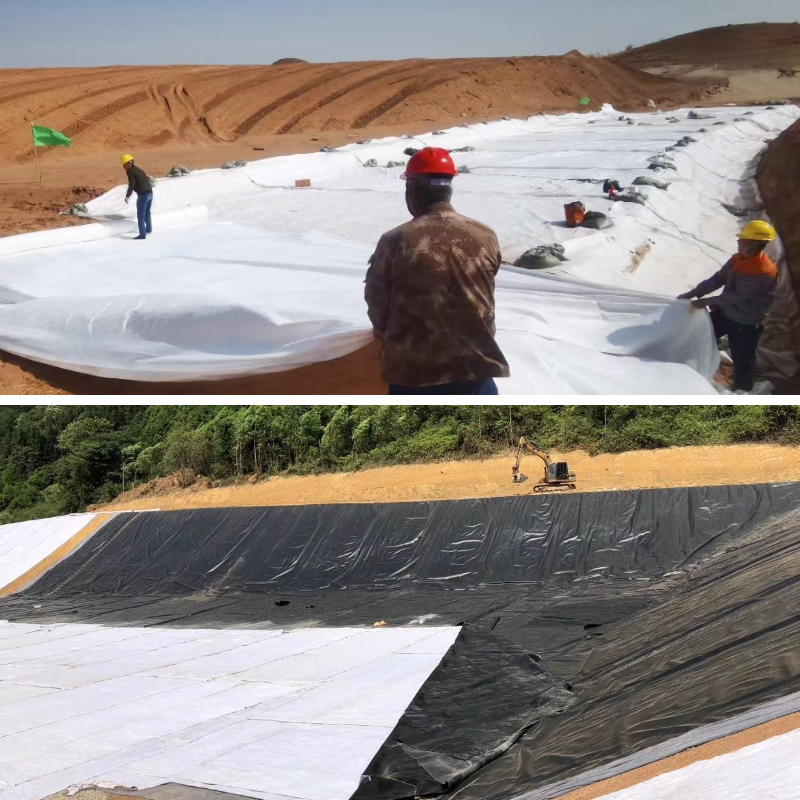

Water conservancy projects are a core application area for geotextile waterproofing, focusing on addressing the risks of "leakage loss" and "structural collapse" in dams, canals, reservoirs, and other locations, while also ensuring the ecological compatibility of water bodies and soils.

Dyke/Embankment Engineering: Layable on the water-facing slope of a dam or within the dam body, it forms a continuous anti-seepage layer, preventing river water from seeping into the dam body and causing pipe bursts and landslides. It also allows moisture to escape from the dam body, preventing soil softening due to accumulated water and ensuring the long-term stability of the dam. (This material is commonly used in embankment reinforcement projects in the middle and lower reaches of the Yangtze River in China.)

Artificial Channels/Irrigation Systems: Covering the inner walls of channels reduces leakage and loss during the transportation of agricultural irrigation water and industrial water, making it particularly suitable for water-saving irrigation needs in arid and semi-arid regions. Reservoirs/Storage Ponds: Used for seepage prevention at the reservoir bottom and slopes, preventing water from seeping into the ground or surrounding soil, maintaining the reservoir's effective water storage capacity. For small ecological reservoirs, this waterproofing solution can also prevent contamination of aquatic organisms by chemical waterproofing materials, making it suitable for ecological aquaculture and landscape water use.

2. Transportation Infrastructure: Core Solutions: "Subgrade Moisture Prevention + Structural Durability"

Transportation projects place extremely high demands on "subgrade stability and structural aging resistance." Geotextile waterproofing can specifically address issues such as rainwater erosion and freeze-thaw damage, extending the service life of roads and tunnels.

Highway/Railway Subgrade: Laid between the top subgrade and the pavement base, it forms a "moisture-proof barrier" to prevent rainwater from seeping into the subgrade soil—preventing soil softening by water, which can lead to pavement subsidence and cracking. In high-altitude and cold regions, it can also reduce damage to the subgrade caused by freeze-thaw cycles. Tunnel Engineering: Serving as a secondary waterproofing layer for tunnels, it adheres to the tunnel's inner walls, preventing water seepage from the mountain and entering the tunnel, corroding steel and damaging electromechanical equipment. Its flexibility also allows it to adapt to slight deformations in the tunnel structure, preventing cracking in the waterproofing layer.

Bridge Engineering: Applied beneath bridge supports and on the underside of bridge deck pavement, it prevents rainwater from penetrating the main bridge structure (such as beams and piers), preventing structural hazards caused by steel corrosion. It is particularly suitable for bridge maintenance in rainy regions.

3. Building and Municipal Engineering: Core Solutions: "Spatial Moisture-Proofing + Environmental Adaptability"

Building and municipal applications prioritize "localized waterproofing + construction flexibility." Geotextile waterproofing is adaptable to complex spaces such as basements, rooftops, and landfills, balancing functionality and environmental performance.

Building Basements/Underground Garages: Applied on the basement exterior walls and floor slabs at the soil interface, it replaces traditional membrane waterproofing. Its enhanced puncture resistance effectively prevents groundwater from seeping into the interior, preventing moisture buildup in walls and ground leakage. Roof/Terrace Waterproofing: Used in green roofs and flat roof waterproofing projects, it's laid between the waterproofing layer and the insulation layer, preventing rainwater from seeping in while allowing moisture from the roof to escape. Its lightweight design reduces roof loads, making it suitable for renovations of older buildings.

Municipal Landfills: As the core material in the landfill's "double-layer anti-seepage system" (used in conjunction with a geomembrane), it prevents landfill leachate from seeping into the soil and groundwater, thereby polluting the surrounding ecosystem. It also filters impurities from the leachate, reducing pressure on subsequent treatment systems.

4. Environmental Protection and Ecological Engineering: Core Solutions: "Ecological Protection + Long-Term Seepage Control"

Ecological engineering projects place stringent demands on environmentally friendly materials and compatibility with nature. Geotextile waterproofing can prevent seepage while minimizing damage to soil and water ecosystems. Constructed Wetlands/Eco-ponds: Used to prevent seepage at the bottom of wetlands, preventing rapid water infiltration and maintaining stable water levels. Their environmentally friendly materials do not release harmful substances, ensuring the normal growth of aquatic plants and microorganisms within the wetland, making them suitable for urban ecological restoration projects.

Mine Reclamation/Soil Remediation: These are laid in abandoned mine pits and contaminated soil remediation areas to form an impermeable layer. This prevents heavy metals and harmful chemicals from the contaminated soil from seeping into groundwater, while also retaining water needed for remediation and assisting with vegetation regeneration (e.g., coal and metal mine reclamation projects).

Aquaculture Ponds: Covering the bottom of aquaculture ponds, replacing traditional cement-hardened pond bottoms, prevents water seepage while maintaining the permeability of the bottom soil (simulating a natural water environment), minimizing impacts on the growth of aquacultured organisms (such as fish, shrimp, and shellfish) and improving survival rates.

Geotextile waterproofing, a functional geotechnical material made from polymer synthetic fibers, processed through a specialized process and treated with a special coating, is a key waterproofing material in modern engineering projects. Its core properties are threefold: first, it balances waterproofness with breathability, preventing liquid penetration while allowing internal moisture to escape; second, it is highly adaptable to environmental conditions, resistant to corrosion, aging, and puncture, and capable of stable operation in extreme temperatures and humidity; third, it is flexible and environmentally friendly, lightweight and easy to tailor to complex terrains, and made from environmentally friendly, pollution-free raw materials. In terms of application value, it can replace traditional waterproofing materials, reducing construction and maintenance costs. Its combined functionality of "waterproofing + reinforcement + filtration" addresses diverse project needs, making it a preferred waterproofing solution in various fields.