Filter Fabric for Riprap

1. High strength: It has good tensile and tear resistance, and can enhance soil stability.

2. Permeability: Allow water flow to pass through while effectively preventing soil particle loss.

3. Corrosion resistance: resistant to chemical corrosion, acid and alkali, suitable for various complex environments.

4. Convenient construction: lightweight, easy to cut, simple to lay, reducing project costs.

5. Environmental protection and durability: anti ultraviolet, anti-aging, long service life, reducing maintenance requirements.

Product Introduction:

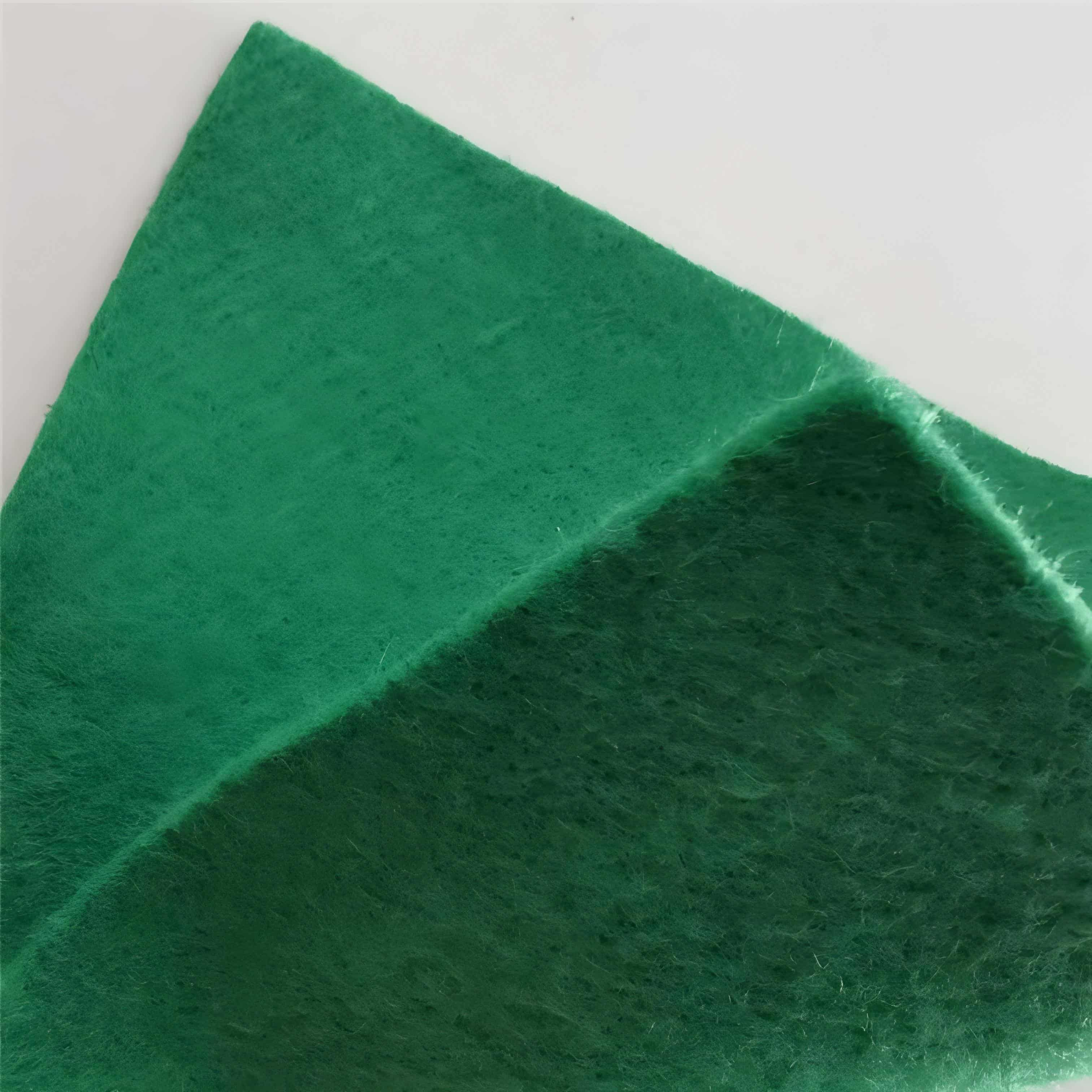

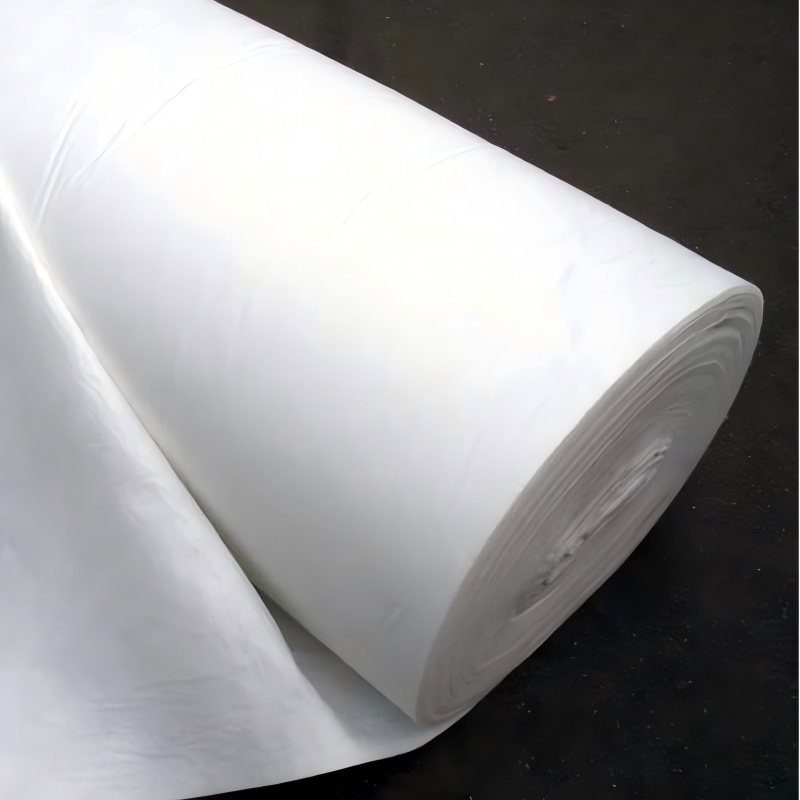

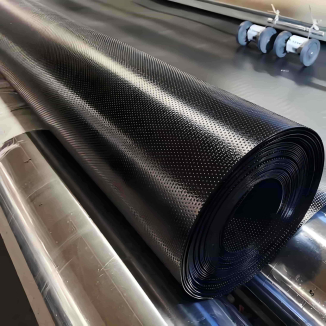

Filter Fabric for Riprap is a permeable geosynthetic material made from synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. The finished product is in the form of cloth, with a width of generally 4-6 meters and a length of up to 50-100 meters. Some products have a width of up to 9 meters and a unit area mass range of 100-1000g/m ². According to the manufacturing process, geotextiles are divided into woven geotextiles (such as machine woven and woven) and non-woven geotextiles (such as short fiber needle punched and long fiber spunbond needle punched).

Key Features

1. High strength and durability

The tensile strength reaches 8-50kN/m, and the bursting strength is ≥ 2.5kN, which can withstand complex stresses during construction and use.

Excellent anti UV aging performance, with a strength retention rate of ≥ 50% after 500 hours of xenon lamp aging.

2. Excellent permeability and filtration performance

The porosity between fibers reaches 60% -90%, and the vertical permeability coefficient is 1 × 10 ⁻² -1 × 10 ⁻⁴ cm/s. It allows water flow to pass through while intercepting soil particles, preventing soil erosion.

3. Reliable isolation function

Effectively separate materials with different physical properties (such as soil and sand, concrete and soft foundation) to prevent structural failure caused by mixing.

4. Auxiliary reinforcement and stress dispersion

After being buried in the soil, it provides additional tensile strength through friction, improves the overall stability of the soil, and reduces uneven settlement.

5. Dual function of protection and drainage

Buffer the damage to waterproof materials caused by external impacts (such as geomembranes), or form flat drainage channels to collect and guide pore water.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

Dam protection: serving as a slope protection filter layer to prevent landslides caused by rainwater erosion; As a filter layer for the initial upstream dam surface in ash storage dams and tailings dams.

River management: laid at the bottom of the canal for anti-seepage protection, or used as a filter layer for pressure relief wells and inclined pressure pipes.

2. Transportation infrastructure

Highways and railways: used for roadbed isolation and reinforcement, soft foundation treatment, retaining walls, and bridge abutment drainage; Prevent reflection cracks in asphalt pavement and extend service life by 30% -50%.

Airport construction: As an isolation layer between runway ballast and foundation, it enhances the bearing capacity.

3. Environmental Protection Engineering

Landfill site: serves as a cushion protective layer and leachate collection and drainage system to prevent harmful substances from infiltrating the soil.

Sewage treatment tank: Isolate sewage from the tank structure to prevent corrosion.

4. Municipal construction

Underground structures: protect basements, tunnel waterproof layers, or serve as wrapping materials for underground pipelines.

Sports field: laid on the foundation layer of football fields and golf courses to enhance drainage performance and soil stability.

5. Ecological restoration

Artificial wetland: As an anti filter layer, it maintains the hydrological balance of the wetland.

Slope greening: Combining with vegetation to form ecological slope protection and prevent soil erosion.

6. Innovative applications

Home gardening: As a weed proof cloth laid in garden vegetable fields, it is breathable and permeable while inhibiting weed growth.

Emergency flood prevention: Temporary covering of roof or balcony leakage points to quickly drain rainwater.

DIY creativity: Cut into storage baskets, pet bed mats, or picnic mats to create industrial style homes at low cost.

Geotextile, with its characteristics of "small material, large function", has become an indispensable "invisible guardian" in modern engineering, continuously promoting the sustainable development of infrastructure construction.