Geotextile Products

Efficient drainage filtration: With excellent permeability, it can quickly remove excess water from the soil, while intercepting sediment particles to avoid blockage of drainage channels.

Strengthening soil bearing capacity: Dispersing soil stress, enhancing soil integrity, reducing settlement deformation, and lowering the risk of engineering collapse.

Durable and anti-aging: It is made of high-strength synthetic fiber, which is resistant to ultraviolet rays, acid and alkali corrosion and microbial erosion, and extends the service life of the project.

Convenient and energy-saving construction: lightweight texture, easy cutting and splicing, reducing environmental damage caused by the project, in line with the concept of green construction.

Multi functional protection: It has multiple functions such as isolation, reinforcement, and anti-seepage, and is suitable for various scenarios such as roadbeds, dams, and environmental protection.

Product Introduction:

Geotextile Products are permeable geosynthetic material made from high-strength synthetic fibers such as polyester and polypropylene, or natural fibers, through processes such as needle punching, weaving, and non-woven weaving. Its core positioning is the "functional link" between engineering soil and the environment. The mainstream synthetic fiber material used has the advantages of tensile resistance, corrosion resistance, and microbial degradation resistance. Combined with the porous structure formed by non-woven technology, it can achieve the dual function of "intercepting sediment and dispersing stress"; At the same time, it has the composite performance of drainage filtration, soil reinforcement, isolation protection, and anti-seepage assistance, which can adapt to complex outdoor environments.

It is lightweight per unit area, easy to construct (manual laying efficiency is 3-5 times that of traditional materials), and the comprehensive cost is 20% -30% lower than traditional solutions. Unlike visible building materials such as cement and steel, geotextiles act on the interior of soil or between structural layers, optimizing soil mechanical properties, improving engineering environment, and fundamentally enhancing engineering stability and service life. They are key auxiliary materials in modern civil engineering that are "low-cost and cost-effective".

Product Parameters:

| project | metric | ||||||||||

| Nominal strength/(kN/m) | |||||||||||

| 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

| 1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

| 2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

| 3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

| 4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

| 5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

| 7 | Width deviation rate /% ≥ | -0.5 | |||||||||

| 8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

| 9 | Thickness deviation rate /% ≥ | -10 | |||||||||

| 10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

| 11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

| 12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

| 13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

| 14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Highway and railway engineering: solving the problem of roadbed stability

Core requirement: Prevent roadbed settlement and prevent roadbed softening caused by rainwater immersion;

Function value:

Isolation: prevent the mixing of roadbed sand and gravel with the underlying soft soil, to avoid the loss of sand and gravel and the loosening of roadbed structure;

Drainage: Quickly drain rainwater inside the roadbed to prevent water accumulation and reduce soil bearing capacity;

Reinforcement: Enhance the overall tensile resistance of the roadbed, reduce the settlement of the roadbed caused by vehicle driving, and extend the service life of the road (experimental data shows that the service life of the roadbed with geotextile can be extended by 1.5 to 2 times).

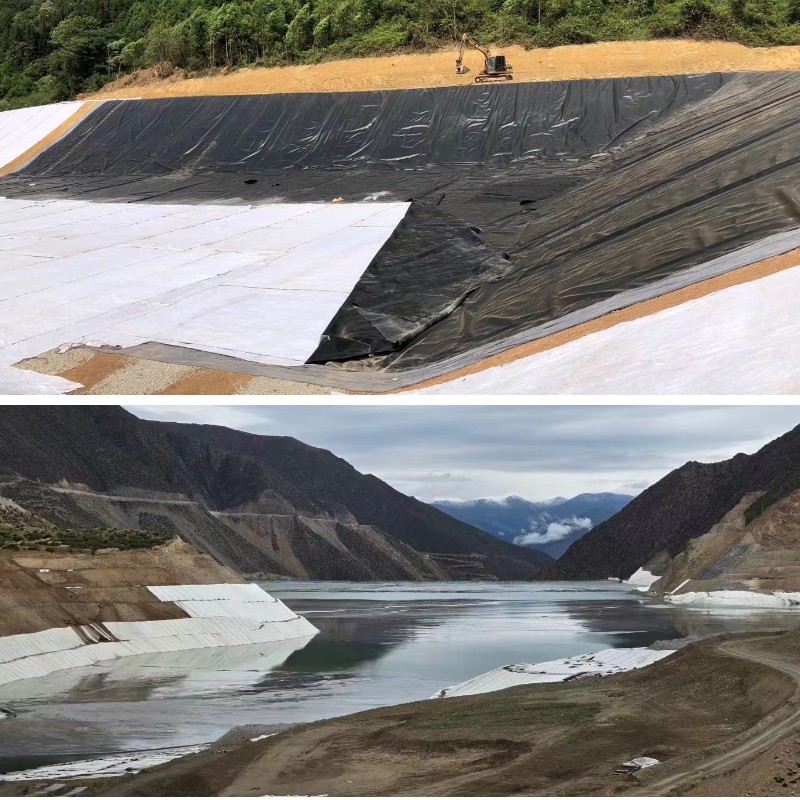

2. Water conservancy and dam engineering: resisting water erosion and infiltration risks

Core requirement: Prevent dam leakage and prevent soil erosion caused by water flow;

Function value:

Anti leakage assistance: forms a "double-layer protection" with the anti-seepage membrane to reduce the risk of leakage after membrane damage;

Anti erosion: The geotextile laid on the upstream slope can directly resist the impact of water flow, avoiding soil erosion of the dam body;

Filtering: The internal laying of the dam body can intercept soil particles and prevent soil layers from experiencing "piping" due to water infiltration (soil particles are lost with water to form voids).

3. Building and Municipal Engineering: Optimizing Foundation and Drainage System

Core requirement: Improve the bearing capacity of soft soil foundation and enhance the efficiency of underground drainage system;

Function value:

Foundation reinforcement: Geotextile is laid in soft soil foundation, and combined with crushed stone cushion layer, it can disperse the load of upper buildings and reduce foundation settlement (suitable for land reclamation and construction projects in low-lying areas);

Drainage optimization: The installation of the underground garage roof can quickly drain rainwater and avoid roof leakage; Laying around the municipal pipeline network can filter sediment and prevent pipeline blockage.

4. Environmental Protection and Ecological Engineering: Balancing Engineering and Ecological Protection

Core requirement: Reduce the damage of engineering to the ecological environment and achieve "symbiosis between engineering and ecology";

Function value:

Environmental isolation: The installation of landfills can prevent leachate from contaminating soil and groundwater, and protect the surrounding ecology;

Ecological restoration: In river restoration, laying soil that can fix the riverbank and allow aquatic plant roots to penetrate without damaging the river ecosystem;

Soil improvement: In the process of mine reclamation, the installation of soil that can isolate the bottom layer of polluted soil provides a stable foundation for surface planting soil and helps with vegetation restoration.

5. Agricultural and Horticultural Engineering: Improving Planting and Irrigation Efficiency

Core requirements: prevent soil compaction, reduce irrigation water loss, and inhibit weed growth;

Function value:

Water and fertilizer retention: Laying it on the bottom layer of the soil can reduce the infiltration and loss of irrigation water, while maintaining soil permeability and avoiding compaction;

Weed prevention: Black geotextile can block sunlight, inhibit weed growth, reduce pesticide use, and meet the needs of green agriculture;

Soil protection: Laying farmland slopes can prevent soil erosion caused by rainwater erosion and protect arable land area.

Geotextile is a permeable geosynthetic material made from synthetic fibers such as polyester and polypropylene, or natural fibers, through processes such as needle punching and weaving. Its core function is to serve as a functional link between engineering soil and the environment. It has comprehensive performance, including drainage filtration, soil reinforcement, isolation and protection, and anti-seepage auxiliary functions. It can replace various traditional materials and is resistant to tension, corrosion, and microbial degradation; At the same time, it is cost-effective, with light unit weight, low transportation and warehousing costs, and construction efficiency 3-5 times that of traditional materials. The overall cost is 20% -30% lower than traditional solutions. As an invisible guardian of engineering, it is different from visible building materials such as cement and steel. It acts inside the soil or between structural layers, and can improve the stability and service life of the project from the root. It is a key auxiliary material with low cost and high cost-effectiveness in modern civil engineering, widely used in five core areas: highways and railways (preventing roadbed settlement and extending road life), water conservancy dams (preventing leakage and erosion), construction and municipal engineering (improving foundation and optimizing drainage), environmental ecology (isolating pollution and assisting in restoration), and agriculture and horticulture (water conservation and weed control).