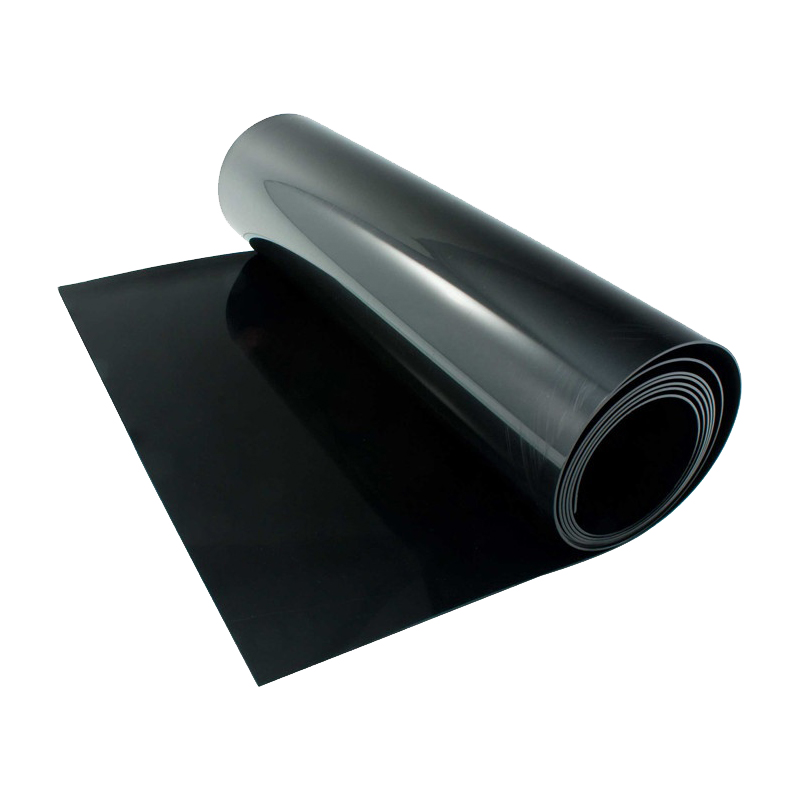

500 micron HDPE Sheet

1. Economic efficiency: Compared with traditional concrete anti-seepage, it has lower cost and shorter construction period.

2. Environmental safety: prevent pollutant leakage, protect soil and groundwater.

3. Strong durability: The lifespan can reach 20-50 years (depending on the material and environment).

4. Multifunctionality: It can be compounded with geotextiles (such as composite geomembranes) to enhance tensile strength and protective performance.

Product Introduction:

500 micron HDPE Sheet refers to a thin film like geosynthetic material with anti-seepage function made from polymer materials such as polyethylene (PE), polyvinyl chloride (PVC), ethylene vinyl acetate copolymer (EVA), and chlorinated polyethylene (CPE) through processes such as blow molding, rolling, and composite. Some geomembranes will be combined with non-woven fabrics and other materials to form composite geomembranes, in order to enhance their tensile strength and puncture resistance.

characteristic

1. Excellent anti-seepage performance: The molecular structure is dense and can effectively prevent the infiltration of water, liquids, or gases. The permeability coefficient is usually less than 1 × 10 ⁻¹¹ cm/s, much lower than traditional anti-seepage materials such as clay.

2. Strong chemical stability: It has good corrosion resistance to acidic, alkaline, salt and other chemical substances, and is not easily eroded in different water qualities (such as sewage, seawater) and soil environments.

3. Good mechanical properties: It has certain tensile strength, tear strength, and puncture resistance, and can adapt to the deformation of the base layer and external impact during construction.

4. Good weather resistance: Some geomembranes (such as PE films with added antioxidants and UV stabilizers) can resist UV aging, high and low temperature changes, and extend their service life.

5. Convenient construction: The material is lightweight (usually weighing 200-1500g per square meter), and can be cut and spliced according to engineering needs. It is connected by hot melt welding, adhesive and other methods, with high efficiency.

6. Strong adaptability: It can adapt to various complex terrains (such as steep slopes and depressions) and can be directly laid on the surface of the base layer without the need for complex foundation treatment.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. Environmental engineering

This is the most core and demanding field of geomembrane application.

Landfill site:

Bottom cushion system: As the main anti-seepage layer, it prevents garbage leachate from polluting groundwater and soil.

Final coverage system: After the garbage is filled, it is used for top coverage to prevent rainwater from entering the pile, reduce leachate production, and collect biogas.

Hazardous waste landfill site: stricter requirements for anti-seepage, usually using a double-layer geotextile liner system with a leakage detection layer in the middle.

Sewage treatment tank/oxidation pond: used for regulating tanks, anaerobic ponds, aeration tanks, etc. in municipal or industrial sewage treatment plants to prevent sewage leakage.

Tailings pond: used to store tailings produced by mining operations, prevent the leakage of wastewater containing harmful substances such as heavy metals, and prevent environmental pollution.

2. Water conservancy engineering

Reservoir and drinking water tank: As anti-seepage liners for the reservoir basin, it reduces water loss and ensures the quality of drinking water.

Channels and canals: laid at the bottom and slopes of the canal to prevent leakage and loss during irrigation or water delivery, and improve water delivery efficiency.

Dams and embankments: used for the central anti-seepage core wall or upstream anti-seepage lining of earth and rock dams, replacing traditional clay core walls, with better results and faster construction.

3. Municipal and Construction Engineering

Underground tunnels and subway engineering: used as a waterproof layer for tunnel structures to prevent groundwater intrusion.

Building basement moisture-proof: laid on the outer side of the foundation slab and side walls to form a reliable moisture-proof barrier.

Roof Garden and Greening: As a root blocking layer and waterproof layer, it prevents plant roots from damaging the roof structure and ensures that the roof does not leak water.

Artificial lakes and landscape water bodies: provide reliable anti-seepage protection for urban landscape water bodies, maintain water levels, and reduce water replenishment costs.

4. Agriculture and Aquaculture

Aquaculture pond: used as a liner for shrimp, fish and other aquaculture ponds to maintain the water level, prevent water exchange with soil, and facilitate water quality control and cleanliness.

Irrigation reservoir: Ensure the storage efficiency of agricultural irrigation water and prevent water resources from seeping into the ground.

5. Other special applications

Petrochemical industry: used for anti-seepage cofferdam of underground oil tanks in gas stations and anti-seepage of storage tanks for chemical raw materials.

Salt field crystallization pool: a bottom liner used for sun drying sea salt to improve salt production efficiency and purity.

Temporary emergency pool: It can be quickly installed as an emergency collection pool in the event of environmental accidents such as chemical spills.

Geomembranes have become an indispensable waterproof material in modern engineering due to their excellent anti-seepage performance, weather resistance, and chemical stability. From water conservancy engineering to environmental governance, from mining applications to agricultural development, its multifunctionality and cost-effectiveness continue to drive industry innovation. With the advancement of technology, the environmental performance and construction efficiency of geomembranes will be further improved, providing more reliable solutions for global infrastructure construction.