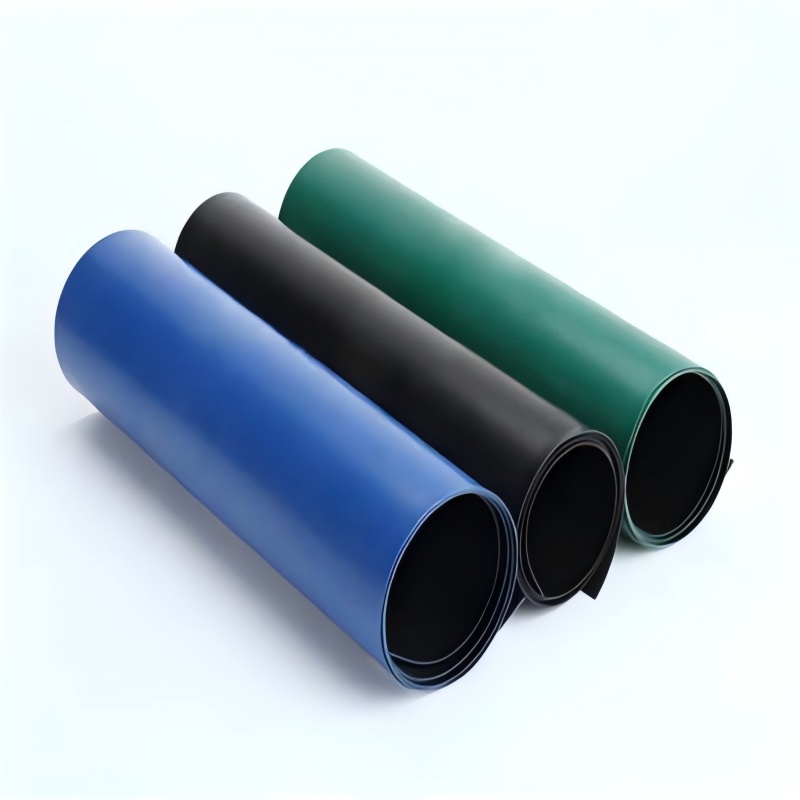

Geomembran 300 micron

1. Environmental safety: prevent pollutant leakage, protect soil and groundwater.

2. Economic durability: Long service life and low maintenance cost.

3. Strong adaptability: Suitable for complex terrain and harsh environments (such as landfills, mines, etc.).

4. Multifunctionality: It has functions such as anti-seepage, isolation, and reinforcement.

Product Introduction:

Geomembran 300 micron is a flexible waterproof barrier material made from high molecular weight polymers such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), EVA, etc., through high-temperature melting, extrusion, or blow molding processes. Its core functions are anti-seepage, waterproofing, isolation, and reinforcement, and it is widely used in fields such as civil engineering, water conservancy engineering, and environmental engineering. According to different materials, it can be divided into HDPE geomembrane (high temperature resistance, UV resistance), LDPE geomembrane (good flexibility), PVC geomembrane (low cost but prone to aging), and composite geomembrane (combined with non-woven fabric to enhance puncture resistance).

Characteristics

1. Super strong anti-seepage performance

The anti-seepage coefficient of geomembrane is extremely low, which can effectively block liquid infiltration. For example, HDPE geomembrane can prevent groundwater pollution from leachate in landfills, and its anti-seepage effect is hundreds of times that of traditional clay layers.

2. Weather resistance and durability

Wide temperature adaptability: It can be used for a long time in an environment ranging from -70 ℃ to 110 ℃. HDPE geomembrane has an increasing melting point at high temperatures and excellent thermal stability.

Strong anti-aging performance: after adding the anti ultraviolet agent, the outdoor exposure life can reach more than 20 years, far exceeding the PVC geomembrane (easy to crack due to UV hardening).

High chemical stability: resistant to strong acids, alkalis, and oil corrosion, suitable for scenarios such as chemical tanks and oil tank anti-seepage.

3. Superior physical performance

High tensile strength: HDPE geomembrane has a tensile strength of ≥ 25 MPa and an elongation at break of ≥ 550%, which can adapt to uneven settlement of the foundation.

Good flexibility: It can be bent and folded, suitable for complex terrains such as riverbank protection and tunnel waterproofing.

Lightweight and easy to construct: The weight per unit area is only 1/10 of concrete, making it convenient for transportation and laying.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

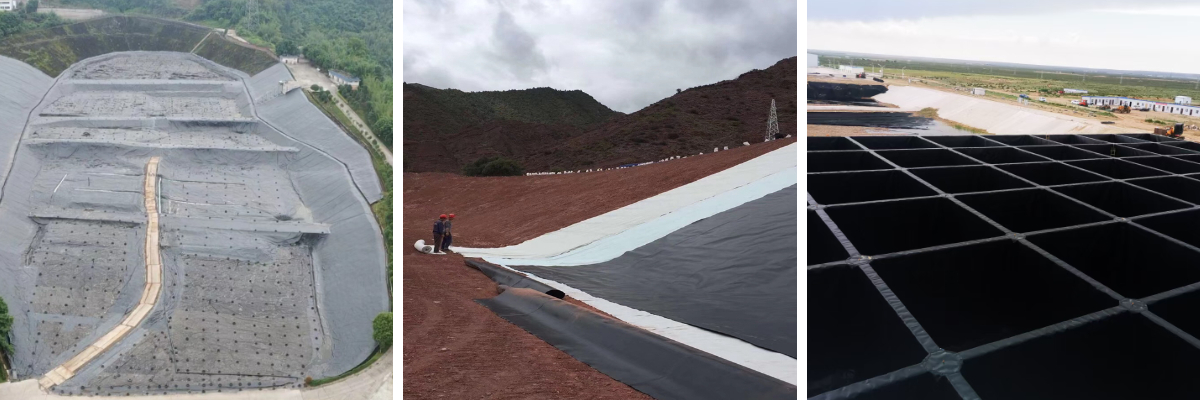

1. Water conservancy engineering

Anti-seepage engineering: anti-seepage lining of reservoirs, dams, and water channels to prevent water leakage and soil erosion. For example, HDPE geomembrane is used for dam foundation seepage prevention in the Three Gorges Project, effectively reducing the amount of leakage.

River management: Flexible protection of bank and slope protection to adapt to water flow erosion and foundation deformation.

2. Environmental Engineering

Landfill site: As the core material of the anti-seepage liner system, it prevents leachate from contaminating soil and groundwater.

Sewage treatment: anti-seepage isolation of regulating tanks and oxidation ponds to prevent sewage leakage.

Soil remediation: isolate contaminated soil layers to prevent the spread of pollutants.

3. Municipal Administration and Architecture

Underground engineering: Waterproofing of subways, tunnels, and basements to prevent groundwater infiltration.

Roof greening: As a waterproof layer, combined with drainage boards to form a planting roof system.

Sewage pipeline: anti-seepage wrapping to prevent pipeline leakage and environmental pollution.

4. Agriculture and Landscape Architecture

Aquaculture: lined fish ponds and shrimp ponds to prevent water quality deterioration and soil pollution.

Irrigation system: Channel anti-seepage, reducing water resource waste.

Artificial lake: landscape water body anti-seepage, maintaining stable water level.

5. Mining and Energy

Tailings pond: anti-seepage lining to prevent tailings liquid from leaking and polluting the environment.

Oil tank foundation: anti-seepage isolation to prevent oil leakage and soil pollution.

Salt field project: salt pond covered with plastic film to improve evaporation efficiency and salt production.

In short, geomembranes play an irreplaceable role in various civil engineering projects due to their unique properties and advantages, providing strong guarantees for the safety, environmental protection, and economic operation of the projects.