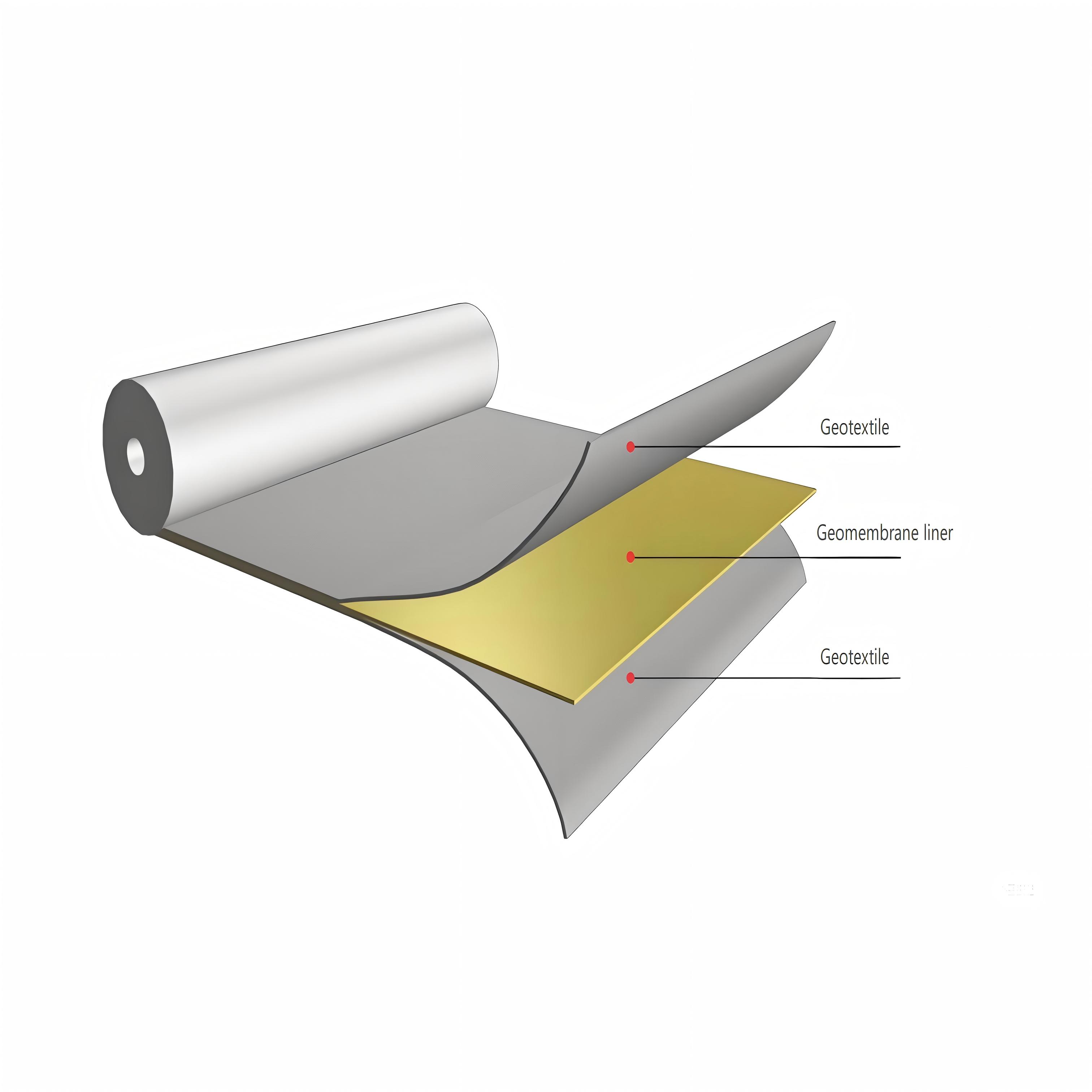

Composite Geo-membrane

Composite Geo-membrane (anti-seepage geotextile) is a multi-layer composite anti-seepage material. Through a hot-melt process, geotextile is combined with polyethylene (PE) or polyvinyl chloride (PVC) anti-seepage membrane, featuring core characteristics such as high strength, zero permeability and chemical corrosion resistance. Its innovative structure can simultaneously achieve the functions of anti-seepage isolation and foundation reinforcement. It is widely used in anti-seepage projects of landfill sites, artificial lakes and mines. It complies with ISO 9001 quality certification and environmental protection standards and is an indispensable key material in water conservancy and environmental protection projects.

Composite Geo-membrane (anti-seepage geotextile) is a multi-layer composite anti-seepage material.

I. Structure and Material Properties

Composite layer design

1. Surface geotextile: polyester (PET) or polypropylene (PP) needle-punched non-woven fabric, with a weight of 100-600g/㎡, water permeability ≥0.1cm/s, protecting the anti-seepage membrane from mechanical damage;

2. Intermediate anti-seepage membrane: Made of HDPE or PVC, with a thickness of 0.2 to 3.0mm and a permeability coefficient of ≤1×10⁻¹¹cm/s, achieving complete anti-seepage.

3. Composite process: Hot-melt bonding or spray adhesive process, with a peel strength of ≥6N/cm, ensuring stable interlayer bonding.

Physical and mechanical properties

1. Tensile strength: Longitudinal ≥20kN/m, transverse ≥18kN/m (tested in GB/T 17642 standard);

2. Puncure resistance: ≥500N (ASTM D4833 standard), resistant to penetration by crushed stones and root systems;

3. Temperature resistance range: -50℃ to 80℃, resistant to freeze-thaw cycles ≥100 times without cracking.

Specifications

Item | Index | ||||||||

Nominal breaking strength /(kN/m) | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 | |

1 | Longitudinal and transverse fracture strength /(kN/m) ≥ | 5 | 7.5 | 10 | 12 | 14 | 16 | 18 | 20 |

2 | The standard strength in the longitudinal and transverse directions corresponds to elongation /% | 30~100 | |||||||

3 | CBR puncture strength /kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3 | 3.2 |

4 | Longitudinal and transverse tear strength /kN ≥ | 0.15 | 0.25 | 0.32 | 0.4 | 0.48 | 0.56 | 0.62 | 0.7 |

5 | Resistant to hydrostatic pressure /MPa | According to the table | |||||||

6 | Peel strength /(N/cm) > | 6 | |||||||

7 | Vertical permeability coefficient /(cm/s) | As per the design or contract requirements | |||||||

8 | Width deviation /% | -1 | |||||||

Item | Film thickness /mm | ||||||||

0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | ||

Resistance to hydrostatic pressure /MPa ≥ | One cloth and one film | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 |

Two pieces of fabric and one piece of film | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | |

Note: The film thickness is between the adjacent specifications in the table, and the corresponding assessment indicators are calculated by the linear interpolation method. When exceeding the range in the table, the assessment indicators shall be determined through consultation between the supply and demand sides. | |||||||||

Ii. Function and Engineering Advantages

High-efficiency anti-seepage and isolation

1. The anti-seepage performance meets the national standard Grade I (permeability coefficient ≤1×10⁻¹¹cm/s), completely blocking the leakage of liquids or gases, and is suitable for anti-seepage in toxic waste landfills and chemical tanks.

2. Isolate different media (such as sewage and soil) to prevent cross-contamination.

Chemical corrosion resistance and weather resistance

1. Resistant to acids and alkalis (pH 1 to 14), resistant to oil and organic solvent erosion, suitable for complex chemical environments;

2.UV aging test (strength retention ≥85% after 3000 hours), suitable for long-term outdoor use.

Convenient construction and adaptability

1. Lightweight design of the roll material (single roll weight ≤500kg), supporting welding splicing, weld strength ≥ 80% of the base material;

2. It can be laid on steep slopes and uneven base surfaces, with a minimum bending radius of no more than 50cm.

Iii. Core Application Fields

Environmental protection and water conservancy engineering

1. Landfill: Bottom anti-seepage layer, site closure and covering system;

2. Artificial lakes/reservoirs: Anti-seepage of the reservoir bottom and bank slopes;

3. Sewage treatment plant: Anti-seepage for regulating tanks and sludge tanks.

Energy and Mining

1. Tailings pond anti-seepage: Preventing heavy metal leakage from polluting groundwater;

2. Petrochemical industry: Anti-seepage for oil storage tank areas and emergency accident pools;

3. Evaporation pool: Lithium extraction from salt lakes, anti-seepage of industrial brine.

Agriculture and municipal engineering

1. Aquaculture: Anti-seepage of aquaculture ponds to reduce water loss;

2. Roof greening: Waterproof layer protection;

3. Subway tunnels: Anti-seepage lining to prevent groundwater infiltration.

Iv. Environmental Protection and Certification

Sustainable production

1. By using 30% recycled PE raw materials, the production energy consumption is reduced by 35% compared with traditional anti-seepage materials.

2. Waste materials can be recycled and remade, in compliance with the EU REACH regulation and RoHS standards.

Authoritative certification

1. China Ten-Ring Certification, NSF/ANSI 61 Drinking Water Safety Certification of the United States;

2. Passed the tests of GRI-GM13 (impermeability performance) and ASTM D6392 (chemical corrosion resistance).

Summary

Composite geomembrane (anti-seepage geotextile) takes zero leakage and multi-scenario adaptability as its core values. Through the combination of composite structure and high-performance materials, it provides long-term anti-seepage guarantee for environmental protection, energy and infrastructure projects. Its scientific parameters (such as ultra-low permeability coefficient and high strength) and environmental protection attributes make it a benchmark product in the global anti-seepage field. In the future, it will be expanded to emerging scenarios such as new energy infrastructure (such as anti-seepage in photovoltaic power plants) and deep anti-seepage in sponge cities, promoting technological innovation in green engineering.