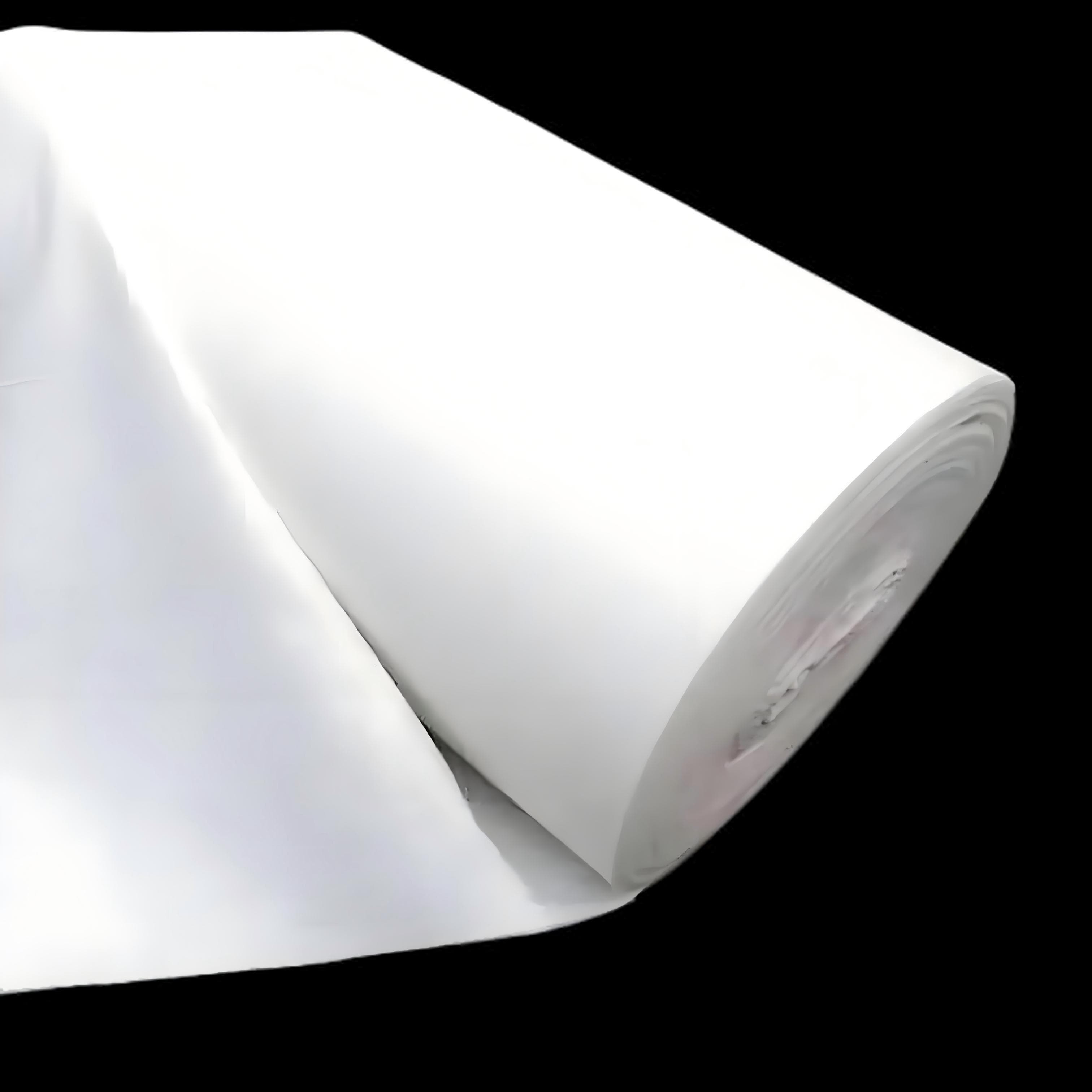

Geotextile 50m

1.Efficient anti-seepage, building a solid engineering barrier:High quality materials endow excellent anti-seepage ability, block moisture infiltration, and safeguard the safety of water conservancy and transportation engineering.

2.Strong load-bearing capacity enhances structural stability:High tensile and tear strength, resistance to soil pressure and load, strengthening the stability of foundation slopes, and extending the service life of the project.

3.Permeable and breathable, optimizing environmental ecology:The special fiber structure achieves both anti-seepage and permeability, draining accumulated water, promoting plant growth, and assisting ecological construction.

4.Long lasting durability, reducing maintenance costs:Anti aging, corrosion, acid-base characteristics, adapt to diverse environments, reduce maintenance and replacement, and reduce long-term costs.

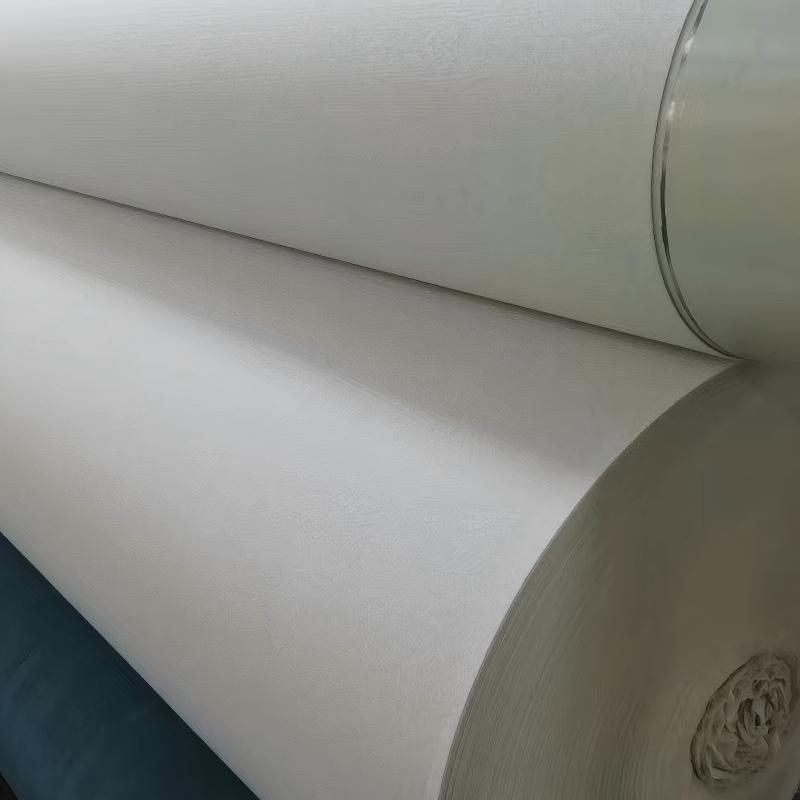

5.Convenient construction and improved work efficiency:The 50 meter length reduces splicing, making it easy to lay quickly, shortening the construction period, and suitable for large-scale engineering construction.

Product Introduction

1.Basic attributes

Geotextile 50m made of high-quality polymer materials , with a standard length specification of 50 meters. The material itself has high tensile strength, tear strength and other physical properties, as well as chemical characteristics of anti-aging, corrosion resistance, acid and alkali resistance, which can meet the use needs of different climates and soil environments.

2.Core functions

Anti leakage protection: With the characteristics of high-quality materials, it effectively blocks moisture infiltration, builds a strong waterproof barrier for various projects such as water conservancy and transportation, and safeguards the safety of engineering structures.

Structural enhancement: Relying on high tensile and tear strength, it resists soil pressure and external loads, strengthens the stability of engineering structures such as foundations and slopes, and extends the overall service life of the project.

Ecological regulation: By using a special fiber structure to achieve a balance between anti-seepage and permeability, it can not only discharge excess accumulated water in the soil, but also provide a suitable environment for plant growth, and assist in ecological engineering construction.

3.Main features

Strong durability: anti-aging, corrosion, acid-base characteristics make it difficult to damage in a variety of environments, reduce maintenance and replacement frequency, and reduce long-term use costs.

Efficient construction: The 50 meter length design reduces the number of splices during construction, making it easy to quickly lay and install, and can effectively shorten the construction period, especially suitable for the construction needs of large-scale projects.

Functional synergy: Organically combining functions such as anti-seepage, load-bearing, and permeability, while ensuring engineering safety and ecological benefits, to achieve multiple values.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

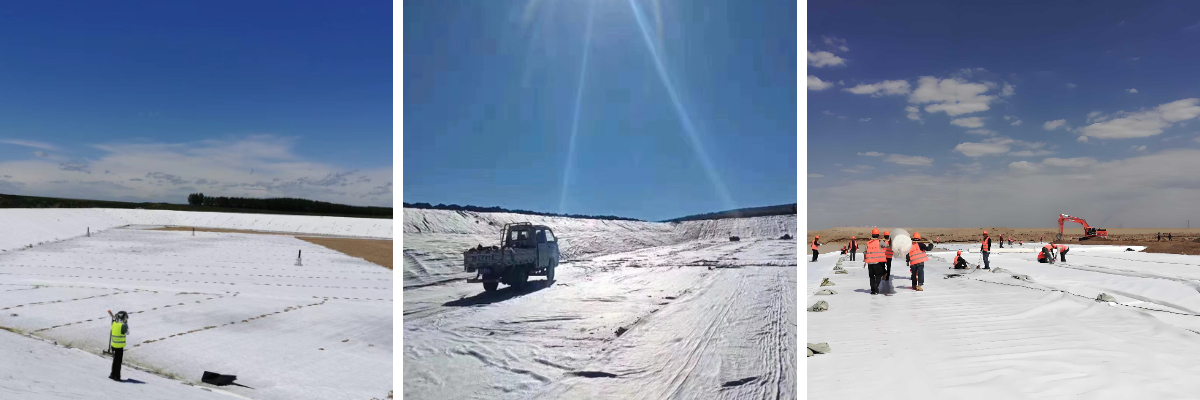

1.Water conservancy engineering field

In the construction of water conservancy facilities such as reservoirs, dams, and channels, 50 meter long geotextile can be used as an anti-seepage layer to be laid at the bottom and slopes of the dam or channel. With its efficient anti-seepage performance, it can block water leakage, reduce reservoir storage losses and channel water transmission losses, and enhance the stability of the dam structure to resist the damage of water flow erosion to the project.

2.Transportation engineering field

Highway and railway construction: In the roadbed treatment stage, geotextile is laid between the roadbed soil and cushion layer to isolate and filter, prevent particle mixing in different soil layers, and reduce roadbed settlement; At the same time, relying on its load-bearing performance to enhance the overall strength of the roadbed, improve the bearing capacity and service life of the road.

Bridge engineering: Laying at the foundation of the bridge and the embankment at the bridgehead can alleviate the problem of vehicle jumping at the bridgehead, and ensure the safe operation of the bridge structure by dispersing the load and enhancing the stability of the foundation.

3.Municipal engineering field

Underground pipeline network engineering: used in the backfilling of trenches for sewage and rainwater pipeline laying, it can effectively isolate the soil from the pipeline, reduce the compression damage of soil pressure on the pipeline, and use its permeability to discharge the accumulated water in the trench, avoiding pipeline corrosion caused by water immersion.

Landfill engineering: As an important component of the anti-seepage lining layer, it is laid at the bottom and periphery of the landfill to prevent the infiltration of leachate and pollution of soil and groundwater, providing protection for environmental sanitation.

4.Ecological engineering field

Slope protection and greening: In ecological restoration projects such as mine greening, river slope, and highway slope, laying geotextile can fix the soil, prevent soil erosion, and provide a suitable environment for plant seed germination and growth due to its permeability and breathability, helping to restore slope vegetation.

Wetland construction project: used for anti-seepage and isolation in wetland terrain shaping, controlling wetland water level, maintaining water balance of wetland ecosystem, and providing a good living environment for wetland animals and plants.

50 meter long geotextile plays a key role in various engineering fields such as water conservancy, transportation, municipal engineering, and ecology due to its characteristics of anti-seepage, load-bearing, permeable, durable, and convenient construction. It can ensure the stability and safety of engineering structures, reduce losses caused by leakage, settlement and other problems, and also meet the needs of ecological environment protection. It provides reliable material support for the efficient construction and long-term operation of various projects, and is one of the indispensable important materials in modern engineering construction.