Geotextile Dewatering Tubes

High strength (tensile strength 10 - 300kN/m), acid and alkali resistance / anti - aging, service life of 10 - 20 years;

The flexible structure can adapt to irregular terrain and has strong resistance to foundation settlement.

High dewatering efficiency: The moisture content of the slurry can be reduced from 90% to less than 50%, and the speed is 3 to 5 times that of the sedimentation tank.

Convenient construction: Precast production, only need to be filled on-site, the construction period is shortened by more than 50%, and it is suitable for complex terrains (such as tidal flats and swamps).

Product Introduction:

Geotextile Dewatering Tubes are flexible tubular structures woven from synthetic fibers such as polypropylene (PP) or polyester (PET), and they have the following core characteristics:

Material properties: High strength (tensile strength of 10 - 300 kN/m), aging resistance, good water permeability, and the ability to intercept fine particles (minimum 0.01mm).

Functional advantages: By filling with sediment, slurry, etc., a flexible engineering structure is formed, enabling functions such as dewatering solid waste (water content can be reduced from 90% to less than 50%), coastal protection, and slope soil stabilization.

Application scenarios: Widely used in projects such as river dredging, tailings treatment, coastal breakwaters, and ecological restoration. The construction is convenient, and the cost is 30% - 50% lower than that of traditional concrete solutions, combining both economic and environmental benefits.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

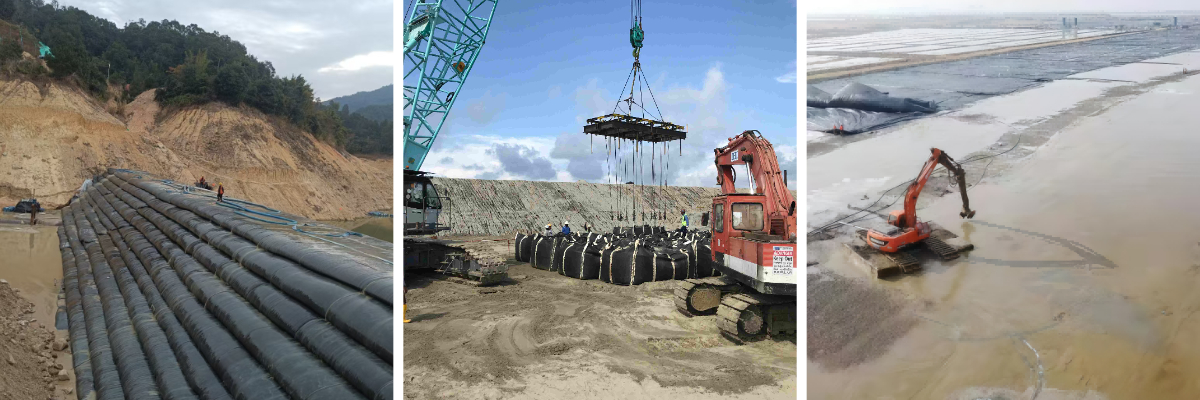

Product Applications:

1.Environment and Solid Waste Treatment

Municipal and Industrial Sludge Treatment: Rapid filtration and dewatering (permeability rate 0.1 - 1m/day), solidify sludge with a moisture content of over 90%, reducing transportation volume and landfill space occupation.

Tailings and Slag Disposal: Fill tailings slurry in mines to form a closed stockpile, prevent heavy metal leakage, and provide a base for reclamation (such as copper mine tailings treatment).

Landfill Closure: Serve as a cover layer to isolate garbage, cooperate with vegetation planting to control odor and rainwater infiltration.

2.Water Conservancy and Water Environment Governance

River and Lake Dredging: Directly fill the dredged slurry for dewatering and solidification, replacing the sedimentation tank, reducing land occupation and treatment costs (such as the Yangtze Estuary Waterway Dredging Project).

Coastal and Dike Engineering: Fill with sand to form breakwaters and revetment retaining walls, with a wave dissipation rate of 70%-90%, suitable for coastal areas (such as the Dutch Delta Coastal Protection).

Reservoir and Dam Seepage Prevention: As an anti-filtration layer to wrap the dam foundation, prevent piping, or be used for cofferdam construction (such as the hydropower station closure project).

3.Civil Engineering and Special Scenarios

Soft Soil Foundation Treatment: Filled sand bags are used as cushion layers or subgrades of embankments to enhance the bearing capacity of the foundation and adapt to poor geological conditions such as swamps and tidal flats (e.g., coastal highway construction).

Emergency Rescue Projects: Pre - fabricated empty bags can be quickly filled with sand for flood control and prevention (e.g., blocking pipe bursts in river embankments), or for building temporary retaining walls after an earthquake.

Aquaculture and Reclamation: They are used to enclose aquaculture ponds or salt pans. The flexible structure can adapt to water level changes, and the cost is lower than that of traditional stone - built dams.

4.Ecological Restoration Projects

Cultivation of Coastal Wetlands and Mangroves: Fill sand and sediment into geotextile bags to form artificial islands or embankments, providing a stable substrate for mangrove seedlings and promoting coastal ecological restoration (such as the wetland restoration in the Pearl River Delta).

Slope Greening and Soil and Water Conservation: Stack into a stepped structure, fill with imported soil, and then plant vegetation, which is used for ecological soil fixation on the slopes of highways and mines (such as the slope protection of the Qinghai-Tibet Railway).