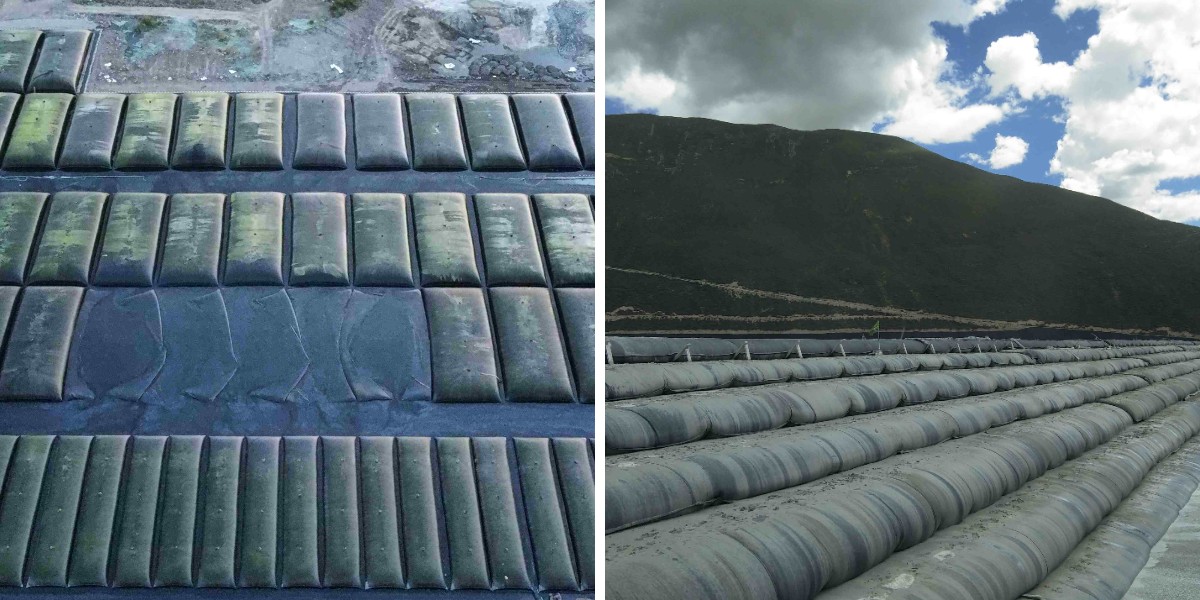

Coastal Protection Geotextile Tubes

1. Resource recycling

It can effectively handle dredging sludge, industrial waste and other waste, achieve the goal of "turning waste into treasure", reduce landfill land occupation and environmental pollution.

2. Low cost

Compared to traditional sand and gravel filling or concrete structures, geotextile bag materials have lower costs and can be used on-site to reduce transportation costs.

3. Strong durability

Geotextiles have strong resistance to corrosion and biological erosion, and the stability of the consolidated structure is high, with a service life of several decades.

4. Eco friendly

During the construction process, there is no dust or noise pollution. After consolidation, vegetation can be planted on the surface to restore the ecological environment, making it suitable for ecological engineering construction.

Product Introduction:

Coastal Protection Geotextile Tubes are large tubular enclosure made of high-strength geotextile fabric (such as polypropylene) through special weaving or sewing processes. Its diameter and length can be flexibly customized according to engineering requirements, with a maximum length of tens of meters. The interior is filled with materials such as silt, sludge, and sludge, and after dehydration and consolidation, a stable structure is formed. It is widely used in fields such as water conservancy, environmental protection, and marine engineering.

characteristic

1. High strength and durability

The tensile strength reaches 45-200kN/m and can withstand high-pressure filling and long-term loads.

UV resistant, acid and alkali resistant (pH 2-13), suitable for harsh environments.

The suture site has high strength, low risk of bag bursting, and a service life of over 10 years.

2. Flexibility and customizability

The size can be adjusted as needed, and the diameter and length are flexible and adaptable to different site conditions.

Stackable transportation, saving space and reducing logistics costs.

3. Environmental Protection and Safety

Fully enclosed construction, no noise pollution, avoiding secondary pollution (such as silt leakage).

The dehydrated water can be reused and meets environmental standards.

4. Efficient dehydration and consolidation

The pores of geotextiles allow water to seep out while retaining solid particles, achieving mud water separation.

The volume of sludge can be reduced by over 90% within one month, and the solidified material can be used for backfilling or resource utilization.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1. Water conservancy engineering

Embankment and dam construction: replacing traditional stone throwing embankments for coastal protection, breakwaters, and river embankment reinforcement.

Cofferdam and interception: Quickly construct temporary water retaining structures, such as construction cofferdams and river interception.

2. Environmental Engineering

Sludge dewatering and disposal: treating urban sludge, industrial waste, and river sludge to achieve reduction and harmlessness.

Polluted sediment treatment: used for dredging projects in lakes, reservoirs, and ports to prevent the spread of heavy metals and organic matter.

3. Ocean Engineering

Artificial islands and land reclamation: For example, the Amwaj Islands project in Saudi Arabia utilized geotextile bags to build embankments and reclaim 620 hectares of land.

Shore protection and wave barrier: resist tidal and wave erosion, and protect the stability of the coastline.

4. Agriculture and ecological restoration

Saline alkali land improvement: By filling with freshwater silt, reducing soil salinity and improving the quality of cultivated land.

Wetland restoration: Construct ecological slope protection, promote vegetation growth, and restore aquatic ecosystems.

5. Industry and Mining

Tailings treatment: Solidify mining waste to reduce environmental pollution.

Fly ash disposal: Processing waste from power plants to achieve resource utilization.

Geotube bags have become an indispensable geosynthetic material in modern engineering due to their high strength, environmental friendliness, economy, and flexibility. From water conservancy protection to environmental governance, from ocean development to ecological restoration, its application scope continues to expand, providing innovative solutions for sustainable development. With technological advancements, geotextile bags will be further optimized in terms of material properties, construction processes, and intelligent management, driving the industry towards a more efficient and green direction.