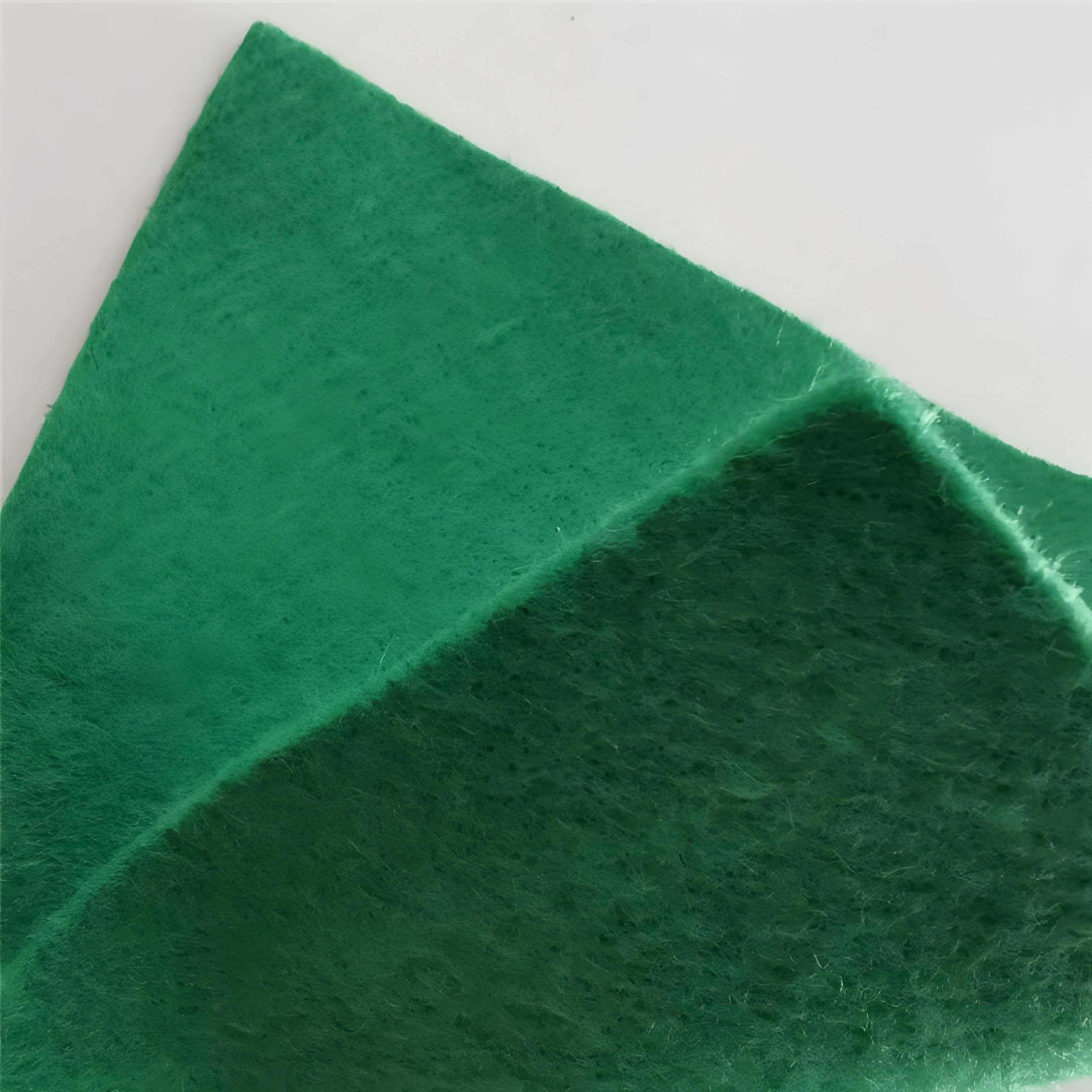

Biodegradable Geotextile Fabric

1. Long term isolation effect: Laying geotextiles between soil layers with different characteristics can effectively isolate them, prevent them from mixing with each other, maintain their respective structural integrity and design functions, thereby improving the overall stability of the structure.

2. Reliable reinforcement effect: disperses the load on the soil, limits the lateral displacement of the soil, thereby improving the bearing capacity and deformation resistance of the soil, just like adding "steel bars" to the soil.

3. Efficient drainage and filtration function: In the drainage system, geotextile is wrapped around the drainage material, which can ensure the smooth discharge of groundwater into the drainage body and prevent the surrounding fine-grained soil from flowing into the drainage system and blocking it, ensuring the long-term effectiveness of the drainage facilities.

Product Introduction:

Biodegradable Geotextile Fabric is a textile material specifically used in civil engineering. It is usually defined as a planar fiber structure material made of permeable, high molecular weight polymers such as polypropylene and polyester. It is not an ordinary 'cloth', but an industrial product that has been specially designed and produced with specific engineering properties such as filtration, isolation, drainage, reinforcement, protection, etc. According to different manufacturing processes, geotextiles are mainly divided into two categories: woven geotextiles (made by weaving or weaving fibers in a certain direction) and non-woven geotextiles (made by randomly or directionally arranging fibers and then using needle punching, thermal bonding, or chemical bonding). They play an indispensable "multifunctional role" in engineering, silently enhancing the quality, durability, and safety of the project.

Characteristics of Geotextile

The reason why geotextiles can be widely used in modern engineering is due to their excellent physical and mechanical properties:

1. Excellent physical and mechanical properties: Geotextiles have high tensile strength, tear resistance, and burst strength, which can withstand various external forces during construction and use, and are not easily damaged.

2. Good permeability and filtration: This is one of the core characteristics of geotextiles. It allows water to pass smoothly through its surface while effectively preventing excessive loss of soil particles, forming a perfect filter layer that is only permeable and does not leak soil, preventing soil piping and erosion.

3. Chemical corrosion resistance and biodegradation: Geotextiles made of synthetic fibers have good resistance to chemicals such as acid, alkali, salt, and oil, and are not affected by mold and insect infestation. They have a long service life and can adapt to various harsh soil and environmental conditions.

4. Flexibility and adaptability: Geotextiles have a soft texture and good deformation ability, which can tightly adhere to uneven foundations or complex shaped structures, adapting to the settlement and deformation of the foundation.

5. Easy construction and high efficiency: Geotextiles are supplied in the form of rolls, which are lightweight, easy to cut and lay, and can greatly shorten the construction period and reduce labor costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy and hydropower engineering: This is one of the most core application areas of geotextiles, mainly used in projects such as dams, reservoirs, channels, hydropower stations, etc., to play a role in filtration, drainage, and protection. For example:

Dam anti filter layer: Lay geotextile between the soil on the upstream or downstream slope of the dam and the permeable layer to prevent the soil of the dam from being washed away by water flow, and discharge the accumulated water inside the dam to avoid pipe surge and landslide;

Channel anti-seepage and protection: Laying geotextile (often combined with geomembrane) on the inner wall of the channel not only prevents channel leakage (saves water resources), but also protects the channel slope from water flow erosion, reducing channel maintenance;

Protection of Reservoir Stilling Pool: Geotextile is laid at the bottom of the reservoir's flood discharge and dissipation pool to cushion the impact of water flow on the pool bottom and protect the concrete bottom plate from erosion.

2. Transportation engineering: including highways, railways, airport runways, ports and docks, mainly used for roadbed reinforcement, isolation, drainage, and improving the bearing capacity and stability of roads or sites. For example:

Highway/railway subgrade: Laying geotextile on soft soil foundation to enhance the tensile strength of the subgrade, reduce subgrade settlement and uneven deformation, and avoid pavement cracking; Laying geotextile between roadbed filling (such as gravel) and soft soil to isolate different materials and prevent gravel from sinking into soft soil;

Airport runway base layer: Lay geotextile between the runway base layer and cushion layer to drain the accumulated water in the base layer and prevent runway deformation caused by frost heave;

Port terminal yard: Lay geotextile on the ground base of the yard, reinforce the ground structure, improve the bearing capacity of the yard, and adapt to the heavy load of container trucks.

3. Construction and municipal engineering: mainly used for building foundations, underground garages, sewage treatment plants, landfills, etc., to play a role in anti-seepage, filtration, and isolation. For example:

Building foundation drainage: laying geotextile around the building foundation to drain accumulated water from the foundation soil, accelerate foundation consolidation, and prevent foundation settlement from causing cracking of the building;

Underground garage anti-seepage: Lay geotextile (composite with geomembrane) on the top or bottom plate of the underground garage to prevent groundwater leakage into the garage;

Landfill site: Geotextile is laid at the bottom and surrounding areas of the landfill site (as a protective layer and filter layer for the geomembrane) to prevent soil and groundwater pollution caused by leachate, and to discharge the leachate to the treatment system.

4. Environmental and ecological engineering: including slope protection, soil and water conservation, river ecological restoration, etc., mainly used to prevent soil erosion and protect the ecological environment. For example:

Slope protection: Laying geotextile (often combined with vegetation to form an ecological protection system of "geotextile+vegetation") on road, railway slopes or mine reclaimed slopes to fix the soil, prevent landslides caused by rainwater erosion, and provide a stable base for vegetation growth;

River ecological restoration: laying geotextiles on the bank slopes of rivers to protect the soil from erosion by river water, while allowing aquatic plant roots to penetrate and grow through the geotextiles, maintaining the integrity of the river ecosystem;

Soil and Water Conservation: Laying geotextiles in terraced fields and wasteland management in mountainous areas to reduce surface runoff, prevent soil erosion, and promote soil improvement.

5. Agricultural engineering: mainly used for agricultural water conservancy, greenhouse, aquaculture, etc., to play a role in drainage, filtration, and protection. For example:

Farmland drainage: laying geotextiles in low-lying areas of farmland to remove excess water from the soil, improve soil permeability, and increase crop yields;

Greenhouse foundation: Lay geotextile on the greenhouse foundation to isolate the soil from the greenhouse foundation materials, prevent foundation settlement, and drain accumulated water from the foundation to prevent moisture from affecting the greenhouse walls;

Aquaculture pond: Lay geotextile at the bottom of the pond to prevent soil leakage and filter the pond water to maintain clean water quality.

In summary, geotextile, as a new type of geotechnical engineering material, has revolutionized traditional engineering materials with its excellent performance and wide applications, providing a safer, more economical, and environmentally friendly solution for modern civil engineering construction. It is known as the "smart fabric in engineering".