Cement Blanket Curing Process: Time, Temperature & Moisture Requirements

1. Understanding Cement Blanket and Its Curing Essentials

Cement blanket, a progressive development material, combines the flexibility of cloth with the sturdiness of concrete. At its core, it is a cement impregnated fabric—fibrous fabric infused with specifically formulated cement powder that hardens upon contact with water. This modern cloth has won recognition in slope stabilization, erosion control, emergency repairs, and small-scale building initiatives due to its ease of use and fast placing properties. However, reaching most effective electricity and sturdiness relies upon closely on suitable curing. The curing system regulates the hydration of cement particles inside the blanket, and elements like time, temperature, and moisture at once have an impact on the ultimate performance. Concrete curing tarps play a vital function in preserving these conditions, making sure the cement blanket develops its full structural integrity barring cracks or weaknesses.

1.1 What Is Cement Impregnated Fabric? Core Properties

Cement impregnated material is the basis of cement blanket, consisting of a sturdy fibrous matrix saturated with dry cementitious compounds. The cloth component—often a high-tensile artificial or herbal fiber—provides flexibility earlier than hydration, permitting the blanket to conform to irregular surfaces, curves, and complicated terrains with ease. Once water is applied, the cement particles activate, initiating a hydration response that binds the fibers collectively and types a dense, water-resistant concrete layer. Unlike regular concrete, this fabric eliminates the want for on-site mixing and heavy equipment, streamlining installation. Key residences of cement impregnated material encompass resistance to UV degradation, chemical erosion, and mechanical impact, making it appropriate for each indoor and outside applications. To retain these homes in the course of curing, keeping constant environmental stipulations is essential, and concrete curing tarps are instrumental in defensive the fabric from severe climate and moisture loss.

1.2 Why Proper Curing Matters for Cement Blanket Performance

Proper curing is non-negotiable for cement blanket, as it immediately influences energy development, crack resistance, and long-term durability. The hydration method of cement requires a constant grant of moisture and steady temperature to proceed fully. Insufficient moisture leads to incomplete hydration, ensuing in a weak, porous structure inclined to cracking and untimely deterioration. Fluctuations in temperature can speed up or retard hydration—too high, and the blanket can also set too quickly, forming interior stresses; too low, and hydration might also stall, leaving the fabric underdeveloped. Additionally, wrong curing can compromise the cement blanket’s water-proof capabilities, a necessary characteristic for purposes like drainage structures and slope protection. Concrete curing tarps tackle these challenges with the aid of developing a managed microclimate, conserving moisture and regulating temperature to help most beneficial hydration from begin to finish.

2. Key Curing Factors: Time, Temperature & Moisture

The curing manner for cement blanket is ruled by using three interdependent factors: time, temperature, and moisture. Each thing have to be cautiously managed to make certain the hydration response proceeds uniformly, ensuing in a strong, long lasting remaining product. While cement blanket is designed for fast setting, speeding the curing method or neglecting environmental stipulations can undermine its performance. Whether used in emergency repairs or deliberate construction, adhering to advocated curing parameters—supported by using equipment like concrete curing tarps—ensures the fabric meets its structural specs and provider existence expectations. Below is a distinct breakdown of every quintessential issue and its affect on cement blanket curing.

2.1 Temperature & Moisture Requirements for Optimal Hydration

Temperature and moisture are the most influential elements in cement blanket curing, as they without delay manage the fee and completeness of hydration. Ideal temperatures for curing vary from reasonable to warm, as this speeds up hydration except inflicting speedy moisture loss. Extreme warmth can dry out the cement blanket too quickly, halting hydration and growing floor cracks. Conversely, freezing temperatures can harm the fabric through increasing moisture inside the matrix earlier than hydration is complete. Moisture administration is equally critical—once water is utilized to set off the cement blanket, the floor need to stay persistently damp during the curing period. Concrete curing tarps are the desired answer for moisture retention; they structure a breathable barrier that prevents water evaporation whilst permitting air circulation, keeping off mildew growth. For hot or arid environments, tarps may additionally be paired with periodic misting to fill up moisture, making sure the cement impregnated cloth retains the hydration vital for full energy development.

2.2 Curing Timeframes for Cement Blanket

Curing time for cement blanket varies based totally on environmental conditions, however a structured timeline ensures most beneficial energy gain. Initial placing usually happens inside hours of water application, at some stage in which the cloth transitions from bendy to semi-rigid. However, full curing—where the blanket reaches its most strength—requires extra time. During the first 24 hours, the hydration response is most active, and the cement blanket develops a big element of its closing strength. It is essential to maintain the fabric included with concrete curing tarps throughout this length to stop moisture loss. While the blanket may also be walkable or usable for mild functions inside a day, prolonged curing (several days to a week) is encouraged for heavy-duty purposes like load-bearing surfaces or erosion manage in high-flow areas. The cement impregnated material continues to harden and bond over time, and extended curing enhances its resistance to wear, chemicals, and environmental stressors. Even in favorable temperatures, skipping or shortening the curing timeframe can end result in decreased energy and durability.

3. Best Practices for Cement Blanket Curing

Implementing first-class practices for the duration of curing maximizes the overall performance of cement blanket, making sure it promises on its structural and purposeful promises. The system starts straight away after water application, with the strategic use of concrete curing tarps to create a managed environment. Proper tarp placement—ensuring full insurance and impenetrable edges to forestall wind displacement—is fundamental to keep steady moisture and temperature. For uneven surfaces or vertical applications, tarps ought to be draped loosely to conform to the cement blanket’s structure barring inflicting friction or damage. Additionally, fending off foot visitors or mechanical stress in the course of the preliminary curing segment prevents floor harm and inner cracking. Regular inspections of the tarp and underlying fabric assist pick out moisture loss or temperature fluctuations early, permitting for changes like misting or repositioning the tarp to fix most advantageous conditions.

Conclusion: Mastering Curing for Superior Cement Blanket Results

The curing system is a indispensable step in unlocking the full viable of cement blanket, with time, temperature, and moisture working in concord to make sure strength, durability, and performance. Cement impregnated cloth depends on acceptable hydration to radically change from a bendy sheet to a strong concrete barrier, and concrete curing tarps are imperative equipment in managing this transformation. By grasp the core houses of the fabric and adhering to endorsed curing practices, contractors, landscapers, and DIY lovers can make certain their cement blanket initiatives stand the check of time. Whether used for erosion control, emergency repairs, or ornamental applications, investing time and care in curing will end result in a exquisite end that meets structural necessities and exceeds long-term sturdiness expectations. As cement blanket continues to achieve traction in sustainable construction, studying its curing technique stays key to profitable mission outcomes.

Contact Us

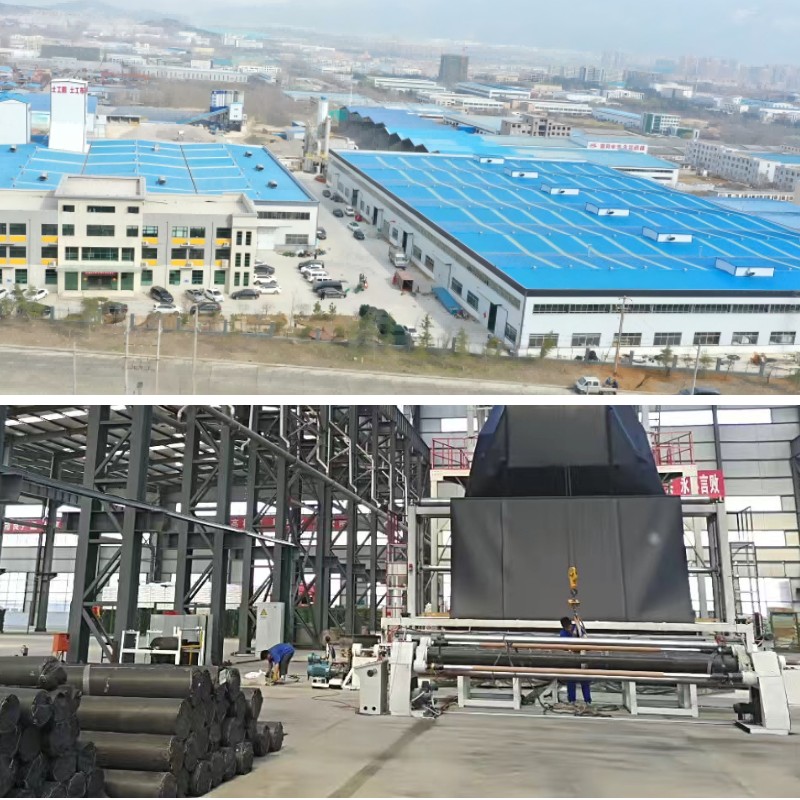

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province