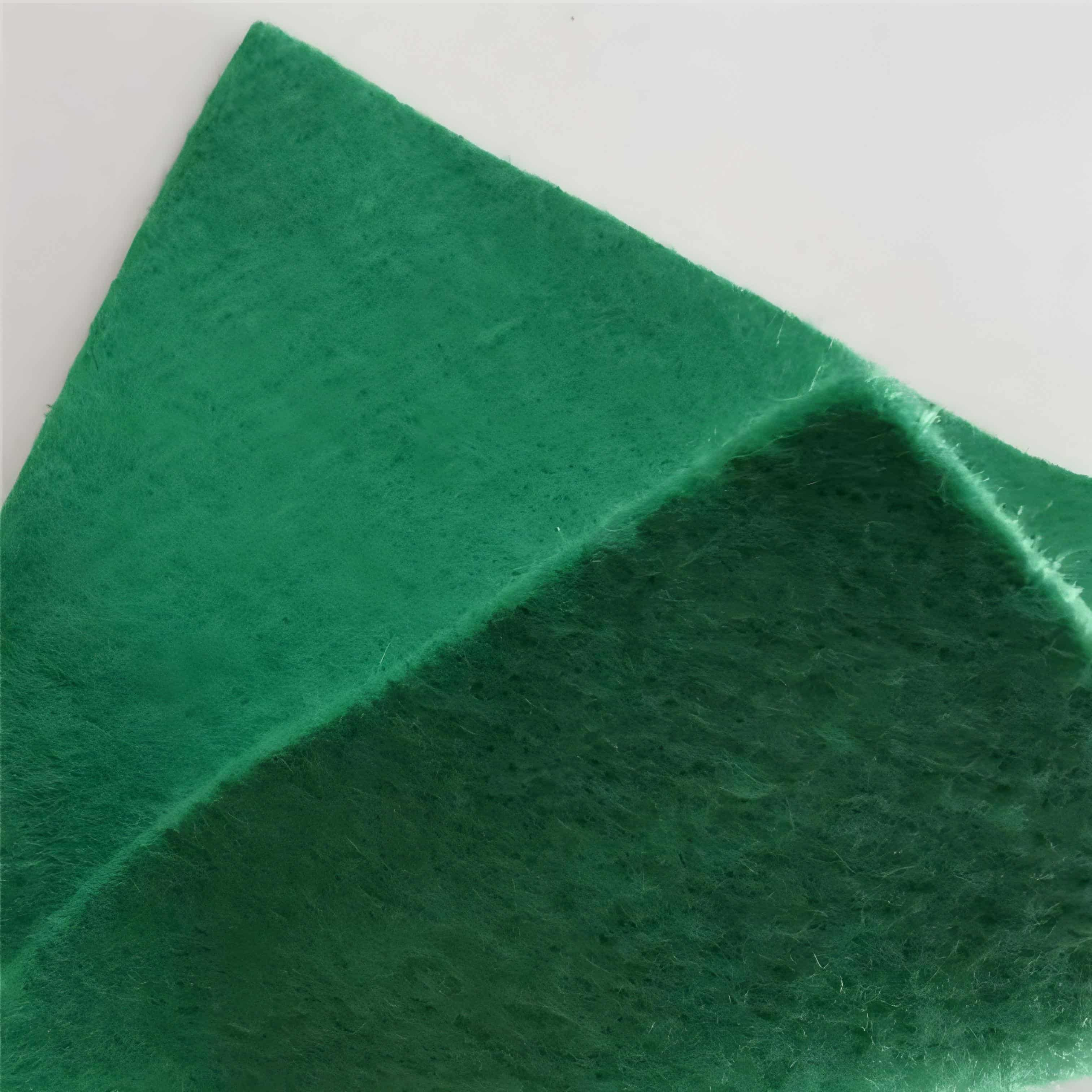

Geotextile Layer

1.Excellent filtering performance:It can effectively intercept soil particles, allow smooth water flow, and prevent soil erosion. It is commonly used as a filter layer in water conservancy and transportation engineering.

2.Good drainage effect:By using its own porous structure to channel water flow, accelerate soil drainage, reduce pore water pressure, and enhance engineering stability.

3.Significant isolation effect:It can separate materials such as sand, gravel, and soil with different particle sizes to avoid mixing and affecting the performance of engineering structures, such as isolating soil and sand in roadbeds.

4.Strong reinforcement ability:Enhance the shear strength of soil, constrain soil deformation, and strengthen the bearing capacity and stability of structures such as slopes and embankments.

5.Convenient construction:Lightweight texture, easy to cut and lay, suitable for complex terrain, can improve construction efficiency and reduce construction costs.

Product Introduction

1.Basic attributes

Geotextile Layer is made from high molecular weight materials such as polypropylene and polyester through processes such as needle punching, weaving, and thermal bonding. The form is mostly in the form of cloth like rolls, with a wide thickness range from a few millimeters to tens of millimeters. It has a certain degree of flexibility and tensile strength, and can adapt to different construction environments and engineering needs.

2.Core functions

Filtering function: Allows water to pass through while intercepting particles in the soil, preventing soil particle loss and ensuring stable seepage in hydraulic engineering, roadbed engineering, etc.

Drainage function: Relying on its own porous structure, it collects and discharges water in the soil, reduces the pore water pressure in the soil, and enhances the stability of the engineering structure.

Isolation function: It can separate materials with different particle sizes and properties to avoid mixing, such as isolating roadbed and foundation soil in road construction, and maintaining the performance of each layer of materials.

Reinforcement function: By enhancing the tensile and shear strength of the soil, constraining its deformation, and improving the bearing capacity and stability of structures such as embankments and slopes.

3.Main features

Geotextiles have good corrosion resistance and aging resistance, and can be used for a long time in complex environments such as acid, alkali, humidity, etc; Lightweight, flexible, easy to transport, lay and construct, adaptable to various terrains; Excellent permeability, which can effectively achieve filtration and drainage functions; In addition, it has the characteristics of relatively low cost and wide applicability, and is widely used in multiple fields such as water conservancy, transportation, municipal engineering, and environmental protection.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1.Water conservancy engineering

In dam construction, geotextile is often laid on the upstream face of the dam body or at the dam foundation as an anti filter layer to intercept soil particles in the dam body, prevent them from flowing away with seepage, and ensure that seepage smoothly enters the drainage system, avoiding hidden dangers such as piping and landslides caused by seepage deformation of the dam body. In channel engineering, whether it is an irrigation channel or a water conveyance channel, geotextile can be laid on the slope and bottom of the channel to resist the erosion of water flow on the channel wall. Especially in areas with loose soil, it can effectively reduce channel collapse, extend the service life of the channel, and improve the water conveyance efficiency of the channel with other materials.

2.Transportation Engineering

In highway construction, laying geotextile between the roadbed and the pavement base can isolate the roadbed soil from the base material, prevent the base aggregate from sinking into the weak roadbed, and use its tensile properties to disperse vehicle loads, reduce roadbed settlement, and lower the probability of pavement cracking; For the renovation and expansion of highways, geotextile can be used at the junction of old and new road surfaces to alleviate road damage caused by settlement differences. In railway track construction, geotextile is laid under the track bed to filter water seepage and prevent fine soil particles from entering the track bed and causing compaction, ensuring the elasticity and drainage of the track bed. In tunnel engineering, geotextile is laid in close contact with the surrounding rock of the tunnel, which can not only discharge water seepage from the surrounding rock, but also block debris from entering the drainage pipeline, protecting the tunnel structure from water damage.

3.Municipal Engineering

In the construction of sidewalks and non motorized vehicle lanes on municipal roads, geotextiles can isolate the base layer from the soil base to prevent the increase of soil moisture from affecting the strength of the base layer; Geotextiles can assist in drainage and prevent surface water from seeping into underground structures beneath hardened surfaces such as city squares and parking lots. When constructing artificial lakes and landscape rivers, geotextile is laid under the anti-seepage membrane to buffer the friction between the anti-seepage membrane and the base layer, avoiding damage to the anti-seepage membrane by sharp stones. Planting soil can be covered above for vegetation greening. At the same time, geotextile can guide the accumulated water under the membrane and prevent the membrane from being damaged due to excessive water pressure.

4.Environmental Protection Engineering

In the anti-seepage system of a landfill site, geotextile is located above the anti-seepage membrane as a protective layer to prevent sharp objects in the garbage from puncturing the anti-seepage membrane. Below it, it can be used as a filtering layer to filter the leachate from the landfill site and prevent impurities from blocking the drainage blind ditch. In the sludge treatment area of sewage treatment plants, geotextiles can be used for sludge dewatering and filtration, intercepting solid particles in the sludge, allowing water to be discharged through the fabric, and improving the dryness of the sludge; Geotextile can prevent soil pollution of the treated water in the walls and bottoms of facilities such as oxidation tanks and sedimentation tanks, while assisting in water circulation and filtration.

Geotextiles have diverse applications in fields such as water conservancy, transportation, municipal engineering, and environmental protection. Their functions of filtration, drainage, isolation, and reinforcement work together to provide important guarantees for the stable, safe, and efficient operation of various projects. From large-scale infrastructure to small-scale municipal projects, geotextiles play an irreplaceable role as key materials for improving engineering quality and reducing maintenance costs. With the development of engineering technology, their application scope will continue to expand.