Geotextile Fabric for Road Construction

1. Enhance soil stability: Geotextiles can effectively separate different soil layers, prevent their mixing and interference, reinforce soil structures, significantly improve the stability of road foundations, and effectively reduce road deformation and damage caused by soil displacement.

2. Extend the service life of roads: It can evenly distribute the pressure borne by the road surface, reduce the probability of ruts and cracks, greatly extending the service life of roads and reducing maintenance and repair costs.

3. Efficient drainage function: Geotextiles have good permeability and can quickly drain accumulated water from road structures, preventing problems such as loose and weak road foundations and reduced strength caused by water immersion, ensuring the structural stability and driving safety of roads in rainy or humid environments.

4. Adapt to complex terrains: This product is lightweight, soft, and easy to transport and lay. Whether in mountainous areas with undulating terrain or areas with complex geological conditions.

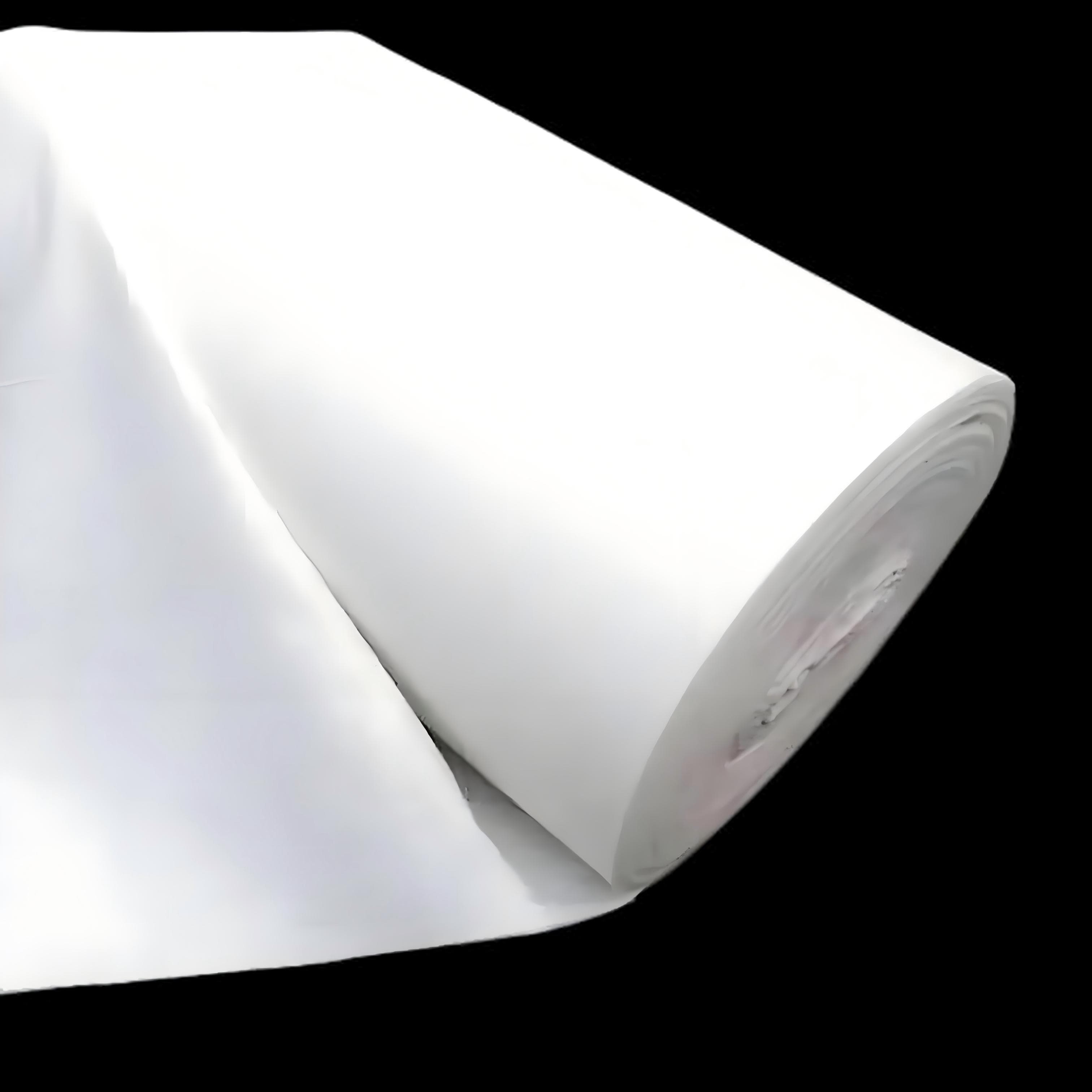

Products Introduction:

Geotextile Fabric for Road Construction is a new type of polymer composite material product designed specifically for road engineering. It is usually made of polymer materials such as polypropylene and polyester through processes such as needle punching, weaving, or bonding. It combines strength and flexibility, playing a key role in road construction, and can provide multiple functions such as protection, reinforcement, and drainage for road structures. It is an indispensable and important material in modern road engineering.

Product Features:

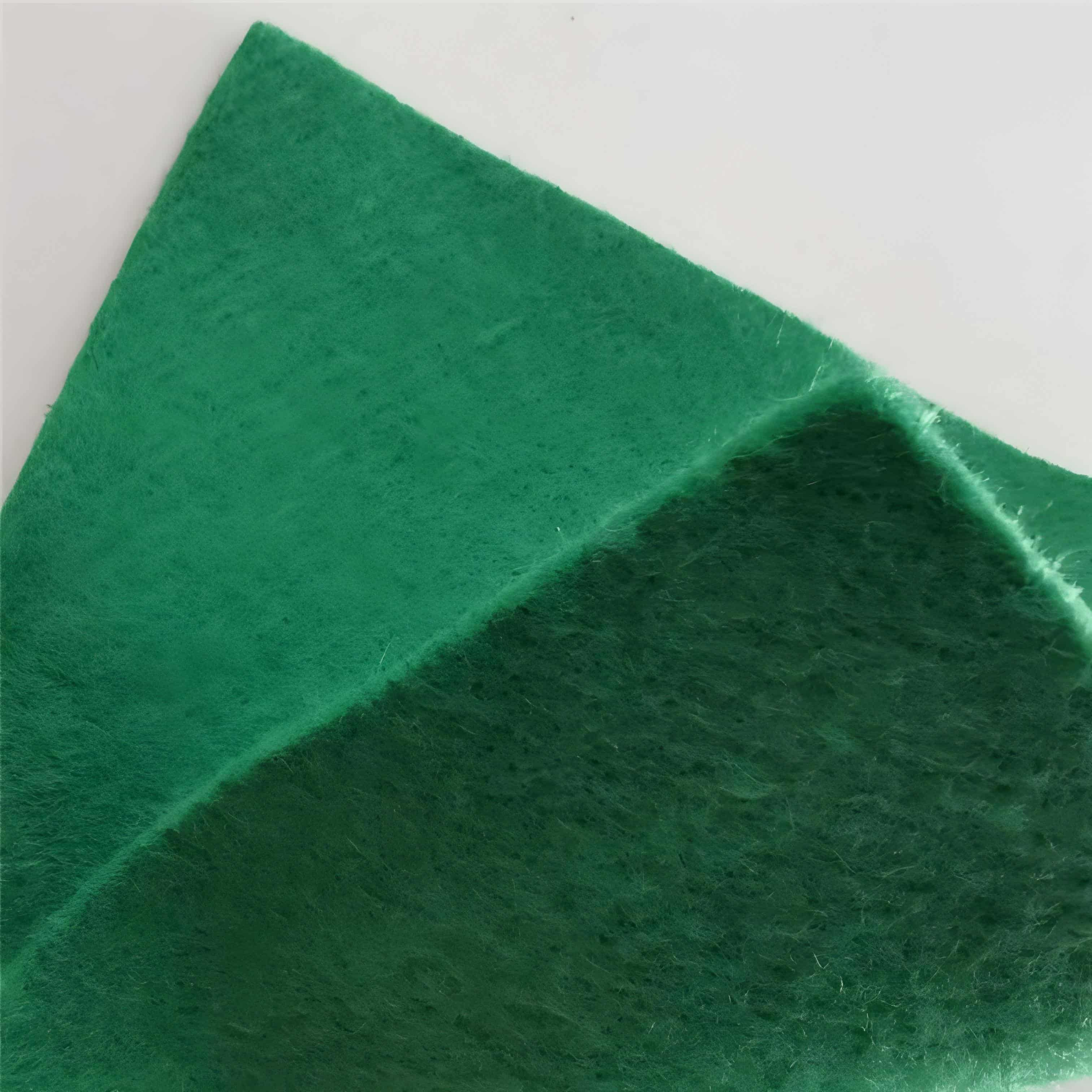

1. High strength and durability: Made of high-quality polymer materials, it has high tensile strength and tear strength, and can withstand various external forces during road construction and use. At the same time, it has excellent aging resistance, acid and alkali resistance, and wear resistance, and can work stably for a long time in different climates and geological environments.

2. Excellent permeability and filtration: It has a large number of evenly distributed pores inside, which can effectively prevent soil particles from passing through while ensuring smooth water flow, playing a good filtering role. This feature enables it to quickly drain accumulated water from road structures, prevent soil erosion, and maintain the integrity of road foundations.

3. Lightweight and easy to construct: The product has a lightweight texture, much lower weight than traditional road reinforcement materials, and low transportation costs and convenience. Moreover, it has good flexibility and can be cut and spliced according to construction needs. The laying process is simple and efficient, and can adapt to different construction sites and terrains, greatly shortening the construction period.

4. Good economy: Although geotextile has a certain procurement cost, in the long run, it can reduce the frequency of road maintenance and repair, extend the service life of roads, and reduce overall project costs. At the same time, its construction process is time-saving and labor-saving, and can indirectly save labor and machinery costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

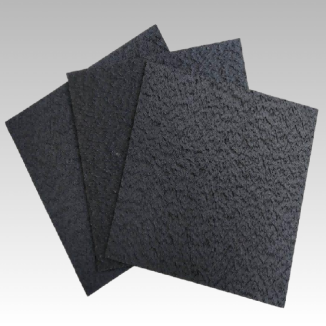

1. Roadbed reinforcement: In road roadbed construction, laying geotextile in the roadbed soil can enhance the bearing capacity of the roadbed, reduce roadbed settlement and deformation, prevent uneven settlement of the roadbed and damage to the road surface, and is suitable for various types of roadbeds, such as filled soil roadbeds, soft soil roadbeds, etc.

2. Road surface isolation: used for isolation between road surface structural layers, such as laying geotextiles between the base layer and the surface layer, and between the base layer and the sub base layer, which can avoid the mixing of materials from different structural layers, ensure the stability of the performance of each structural layer, and improve the overall strength and stability of the road surface.

3. Drainage system: can be applied to drainage facilities on roads, such as side ditches, drainage ditches, infiltration ditches, etc. Laying it in the drainage channel can accelerate the drainage speed, prevent the drainage channel from being blocked by soil, and ensure the smoothness of the road drainage system, especially suitable for road engineering in rainy areas.

4. Slope protection: Laying geotextile on the slopes on both sides of the road can play a role in soil stabilization and slope protection, preventing landslides, collapses and other phenomena caused by rainwater erosion of the slope soil, protecting the ecological environment and road safety around the road, and suitable for slope protection of various slopes.

Geotextile for road construction is a high-performance and widely used engineering material. It plays an important role in road construction processes such as roadbed reinforcement, pavement isolation, drainage systems, and slope protection, thanks to its high strength, durability, permeability, and filtration characteristics. Its lightweight and easy to construct characteristics not only improve construction efficiency, but also reduce construction difficulty; And good economy can save costs for road engineering in the long run. In short, this product provides strong guarantees for the stability, safety, and durability of roads, and is an efficient and reliable ideal material in modern road construction.