Geotextile Stabilization

Enhanced Load-Bearing Capacity: Geotextiles distribute loads over a wider area, reducing stress on the weak subgrade. This significantly increases the bearing capacity of the soil, allowing for better performance under traffic and heavy loads.

Superior Soil Separation: They act as a durable barrier between dissimilar soil layers (e.g., subsoil and gravel), preventing them from mixing. This maintains the integrity and design strength of the aggregate base, a critical factor for longevity.

Effective Erosion Control: By holding soil particles in place while permitting water flow, geotextiles effectively combat erosion from water or wind, protecting slopes, channels, and shorelines.

Cost and Time Efficiency: Reduce the amount of expensive aggregate fill material required. Minimize long-term maintenance and repair costs due to rutting, potholes, and base failure. Installation is quick and requires less heavy machinery.

Long-Term Durability: Our geotextiles are designed to withstand prolonged exposure to harsh underground conditions, providing a permanent stabilization solution that extends the service life of your project.

Products Introduction:

Is your construction or landscaping project struggling with weak, unstable soil? Geotextile stabilization is the engineered solution you need. Geotextiles are permeable synthetic fabrics, made primarily from polypropylene or polyester, designed specifically to separate, filter, reinforce, protect, or drain soils. When used for stabilization, these fabrics integrate with the soil to create a stronger, more durable composite material, solving a multitude of ground-related challenges.

This guide delves into the world of geotextile stabilization, exploring our premium products, their standout advantages, key technical features, and the vast array of scenarios where they deliver unparalleled performance.

Product Features:

High Tensile Strength: Measured in kN/m, ensuring they can withstand significant forces without tearing.

Optimal Pore Size (Apparent Opening Size - AOS): Allows for proper water permeability while preventing soil migration (piping).

Excellent Permittivity & Permeability: Ensures efficient in-plane and cross-plane water flow, preventing water pressure buildup.

Robust Puncture and Tear Resistance: Withstands installation stresses and long-term pressure from sharp aggregates.

UV Resistance: Treated for resilience against sunlight degradation during temporary exposure before being covered.

Roll Dimensions: Supplied in standard and custom roll sizes (widths and lengths) to suit project scales and minimize seams.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

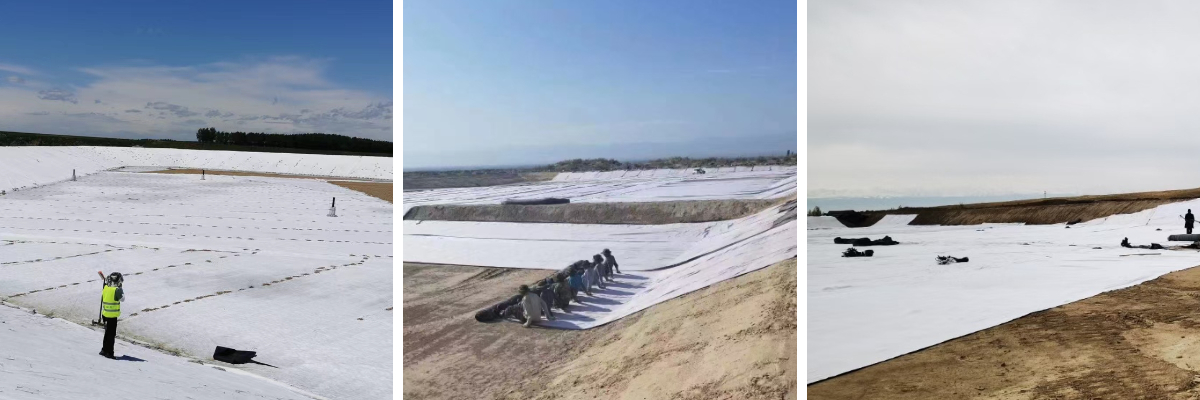

1.Road and Pavement Construction: Unpaved and paved roads, parking lots, airport runways. They stabilize the subgrade, reduce rutting, and prolong pavement life.

2.Railway Track Bed Support: Placed beneath the ballast layer to separate it from the subsoil, preventing contamination and maintaining track alignment and drainage.

3.Foundation and Embankment Support: Used beneath shallow foundations and within embankments over soft soils to improve overall stability and prevent differential settlement.

4.Erosion Control on Slopes: Stabilizes soil on steep slopes, under riprap, or in conjunction with retaining walls to prevent surface erosion and landslides.

5.Landscaping and Recreational Areas: Provides a stable base for gravel pathways, driveways, sport fields, and heavy-use lawn areas, preventing deformation.

6.Parking and Storage Areas: For temporary or permanent heavy equipment storage yards and truck parking areas, preventing ground failure under extreme loads.

Geotextile Stabilization, with its core advantages of "high-strength reinforcement, impact and corrosion resistance, flexibility and adaptability, and economic efficiency," accurately solves the core pain points of "insufficient structural bearing capacity, easy deformation, and high maintenance costs" in civil engineering. It is a key material for achieving "lightweight reinforcement and long-term stability" in various engineering projects. Whether it is roadbed protection in transportation engineering, dam reinforcement in water conservancy engineering, or ground stability in municipal projects, they can significantly improve structural stability and extend the service life of the project through the synergistic effect with the substrate.

Compared with traditional reinforcement materials and processes, geostable fabric has achieved triple optimization in "performance, cost, and construction efficiency" - breaking through the limitations of rigid materials, reducing overall project investment, and adapting to the needs of modern engineering for "green environmental protection and efficient construction". Its widespread application not only promotes the upgrading of civil engineering reinforcement technology, but also provides reliable support for reducing long-term operation and maintenance costs and ensuring engineering safety. It is an indispensable functional geotechnical material in modern infrastructure construction and ecological engineering.