Geotextile Weed Barrier

1. High strength and durability: Synthetic fibers have high tensile strength, tear and burst resistance, corrosion resistance, microbial erosion resistance, and long service life.

2. Good permeability: It has good permeability, allowing water to pass smoothly within or through the plane, while effectively preventing excessive loss of soil particles.

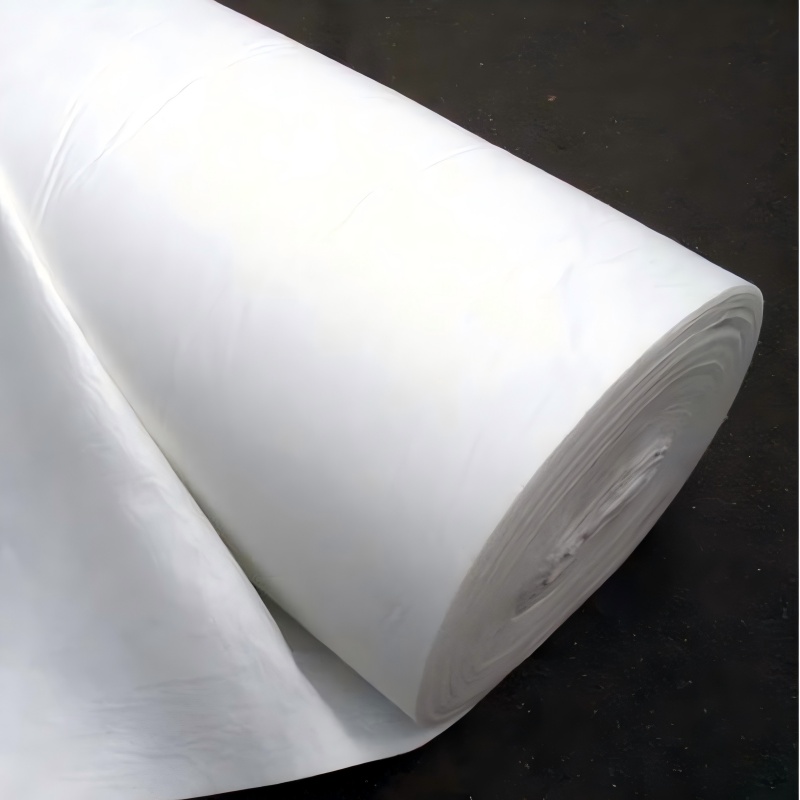

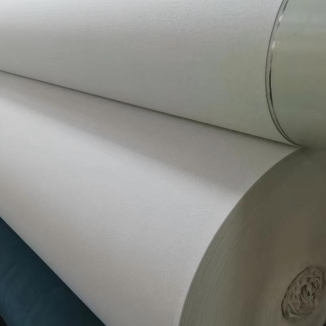

3. Easy construction and high efficiency: The finished product is a roll material, which is lightweight, easy to transport and lay, and can greatly shorten the construction period and reduce the construction intensity.

4. High cost-effectiveness: The material itself has a relatively low cost, coupled with fast construction and the ability to reduce the use of other building materials, the overall project cost is significantly reduced.

Product Introduction:

Geotextile Weed Barrier is a new type of composite material in geotechnical engineering, made from high molecular weight polymers such as polypropylene, polyester, polyethylene, etc., through processes such as spinning, needle punching, weaving, and thermal bonding. It has multiple functions such as filtration, drainage, isolation, reinforcement, and protection, and is widely used in geotechnical engineering fields such as water conservancy, transportation, construction, and environmental protection. It is one of the indispensable key materials in modern engineering construction.

Definition of Geotextile

From the dual dimensions of material properties and engineering functions, the core definition of geotextile can be summarized as: a flexible sheet material made of synthetic fibers or natural fibers as the substrate, processed by specific processes, which can work synergistically with soil, rocks, water and other media, improve the stability of engineering structures, extend the service life of engineering, and reduce engineering costs through its own physical and mechanical properties and functional characteristics.

Its essence is to solve the pain points of poor filtration, soil loss, and structural deformation in traditional geotechnical engineering through the interaction of "material medium structure". For example, in roadbed construction, it can replace traditional sand and gravel filter layers while achieving isolation and drainage functions.

Main characteristics of geotextile

According to the processing technology and functional focus, geotextiles can be divided into types such as needle punched geotextiles, woven geotextiles, and hot clay geotextiles. There are differences in the characteristics of different types, but they generally have the following common characteristics:

1.Physical and mechanical characteristics

High strength and toughness: The fracture strength can reach 10-50kN/m (far exceeding the traditional hemp cloth's 1-3kN/m), and the elongation is 10% -40%. It can adapt to small deformations of soil without breaking, avoiding material tearing caused by soil settlement.

Good permeability: By controlling the fiber porosity (usually 70% -90%), a reasonable permeability rate (10-1000cm/s) can be achieved, which can quickly discharge excess water from the soil and prevent soil particle loss, balancing the contradiction between "drainage" and "filtration".

Good dimensional stability: Within the temperature range of -20 ℃ -80 ℃, the thermal shrinkage rate is less than 3%, avoiding material shrinkage and wrinkling caused by temperature changes and ensuring the flatness of the engineering structure.

2. Chemical stability characteristics

Corrosion and aging resistance: Synthetic fibers (such as polypropylene) have excellent chemical inertness and do not react with acids, bases, or salts; Some geotextiles also add anti ultraviolet (UV) agents, which can maintain a strength retention rate of over 80% within 5 years in outdoor exposure environments, solving the pain points of traditional materials that are prone to corrosion and aging.

Anti biological erosion: The fiber structure does not contain the nutrients required for the growth of microorganisms such as bacteria and fungi, and will not be biodegraded. When used in wetlands, sewage treatment plants, and other scenarios, there is no need to worry about the material being corroded or damaged.

3. Construction adaptation characteristics

Flexible adhesion: It can tightly adhere to irregular soil surfaces (such as slopes and excavation sidewalls) without obvious gaps, avoiding the problem of "gap water accumulation" between traditional rigid materials (such as concrete slabs) and soil.

Easy to splice: Large area seamless splicing can be achieved through methods such as hot welding, stitching, and adhesive bonding, with a splicing strength of over 80% of the parent material strength, ensuring the overall continuity and integrity of the project.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

Embankment and riverbank protection: Needle punched geotextile (weight 300-600g/㎡) is laid on the upstream slope of the embankment, and the surface is covered with sandbags or stone blocks. The "protection+reinforcement" function of geotextile is used to prevent soil loss caused by water flow erosion, enhance the overall anti sliding stability of the embankment, and reduce the risk of embankment failure.

Reservoir and channel filtration and drainage: Lay permeable geotextile at the bottom of the reservoir or on the side walls of the channel to prevent soil particles from entering the water body (to avoid reservoir sedimentation), while draining the permeable water in the soil, reducing the osmotic pressure of the channel slope, and preventing slope collapse.

2. Transportation Engineering

Highway and railway subgrade: A composite layer of "geotextile+geogrid" is laid between the subgrade fill and the foundation (geotextile is responsible for filtering, geogrid is responsible for reinforcing), isolating soil of different particle sizes (to prevent fine soil particles from infiltrating into the coarse soil of the foundation and causing subgrade settlement), while enhancing the bearing capacity of the subgrade, reducing the deformation of the subgrade caused by vehicle driving, and extending the service life of the highway.

Tunnel and bridge engineering: laying geotextile behind the tunnel lining (as a "buffer filter layer") to discharge water seepage from the tunnel surrounding rock and avoid lining cracking caused by accumulated water seepage; Laying geotextile in the backfill soil of the bridge abutment can reduce the settlement difference between the abutment and the roadbed, and solve the problem of "bridge head jumping".

3. Construction and Municipal Engineering

Building foundation pit drainage: Wrap geotextile in the gravel drainage blind ditch on the side wall of the foundation pit, filter out fine particles in the soil around the foundation pit, prevent blind ditch blockage, ensure smooth drainage of seepage, lower the water level in the foundation pit, and avoid foundation pit collapse.

Landfill anti-seepage system: Geotextile (as a "protective layer") is laid between the anti-seepage geomembrane (HDPE film) and the soil to prevent sharp particles (such as stones and tree roots) from piercing the geomembrane in the soil, and to discharge the accumulated water on the membrane, protecting the integrity of the anti-seepage system and preventing the leakage of garbage leachate from polluting groundwater.

4. Environmental Protection and Ecological Engineering

Sewage treatment plant filter: Geotextile is laid under the quartz sand filter layer of the filter as a "supporting filter layer" to prevent the loss of filter material and ensure the smooth passage of treated clean water, thereby improving filtration efficiency.

Slope ecological restoration: In mining restoration and road slope greening projects, geotextile (fixing the surface soil) is first laid, then covered with planting soil and sown. The "protection+water retention" function of geotextile is utilized to prevent soil loss caused by rainwater erosion and provide a stable environment for plant growth.

Geotextile, as a new type of geotechnical engineering material, has become an indispensable part of modern infrastructure construction due to its excellent performance and economic benefits. It cleverly solves many problems in traditional engineering through core functions such as isolation, filtration, drainage, reinforcement, and protection, improves engineering quality, reduces costs and maintenance expenses, and is conducive to environmental protection. The correct selection and laying of geotextile is crucial for the safety and durability of the project.