Geotextile Fabric under Gravel Driveway

1. Isolation and anti mixing: Separate the gravel from the base soil, prevent soil from upwelling and polluting the gravel, and avoid lane settlement and deformation.

2. Reinforced load-bearing: enhances structural integrity, disperses vehicle loads, reduces ground subsidence caused by crushing, and extends lane life.

3. Drainage and flood prevention: quickly drain rainwater, prevent water accumulation from softening the base layer, and avoid muddy and bumpy lanes.

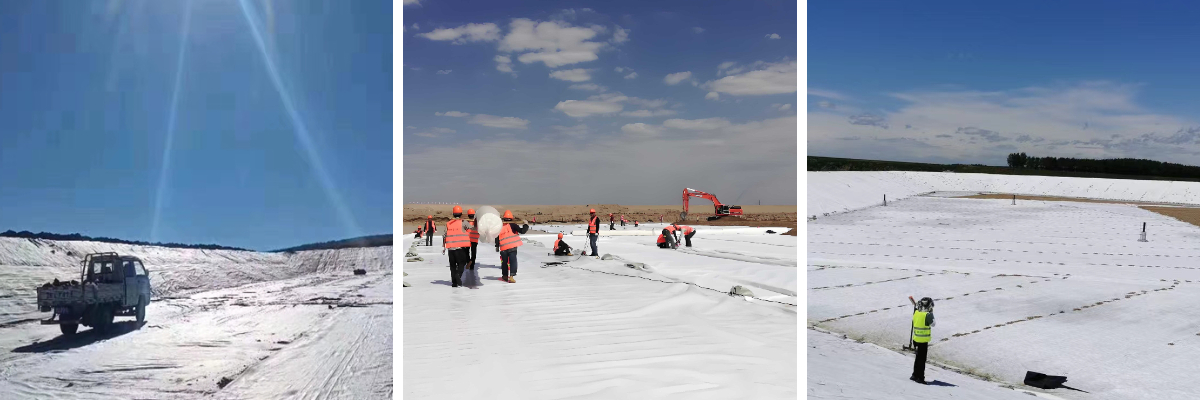

4. Easy to construct: easy to lay, closely attached to the ground, no need for complex processes, reducing laying costs and project duration.

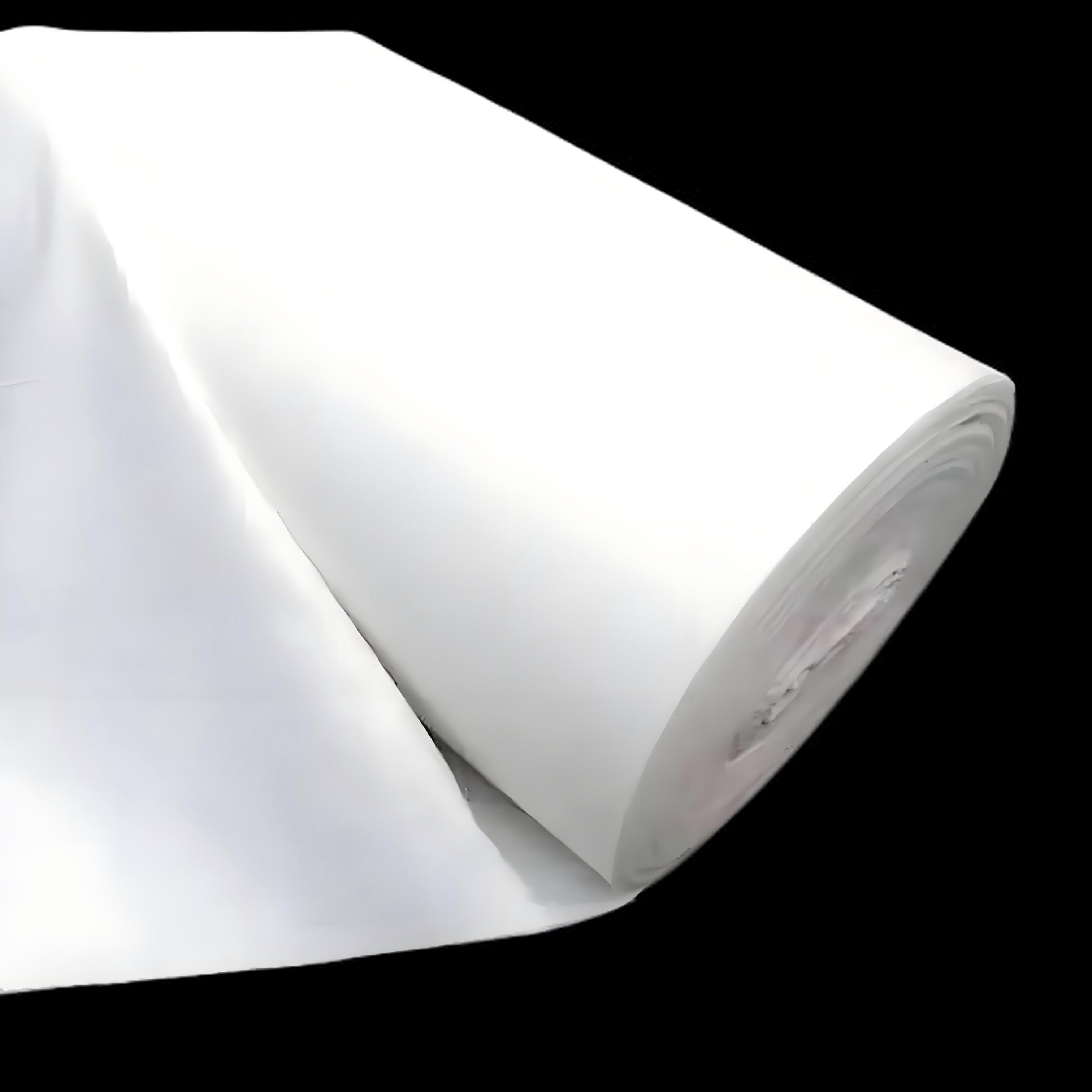

Products Introduction:

Geotextile Fabric under Gravel Driveway is a high-performance geosynthetic material designed specifically for the base layer of gravel lanes. It is made from polypropylene (PP) or polyester (PET) and processed through needle punched non-woven or woven techniques. Its core function is to be laid between the gravel layer and the underlying soil base, and to solve the pain points of short service life and frequent maintenance caused by soil upwelling, load sinking, water accumulation and mud in the gravel lane through the triple functions of "isolation and protection, reinforcement and load-bearing, and drainage and diversion". This product is suitable for various grade lane scenarios such as residential and commercial, and can significantly improve the stability of lane structures and reduce maintenance costs in the later stage. It is an indispensable supporting material in grade lane paving.

Product Features:

1. Strong isolation and prevention of soil material mixing: The fabric pores are fine and uniform (0.05-0.2mm), which can effectively separate the gravel layer from the underlying soil base, prevent soil particles from rushing up to the gravel gap with vehicle compaction or rainwater infiltration, avoid gravel being "polluted" and compacted, maintain lane breathability and drainage, and reduce settlement deformation caused by soil mixing from the root.

2. Reinforcement and anti load settlement: Made of high-strength fiber weaving, the longitudinal/transverse tensile strength reaches 10-30kN/m, and the tear resistance is excellent. After laying, it forms a "composite stress system" with the gravel layer and soil base, which can disperse the pressure generated by vehicle loads (especially heavy vehicles), enhance the overall load-bearing capacity of the lane, reduce the situation of gravel being crushed and sunk, and local potholes, extending the service life of the lane by 3-5 years.

3. Drainage and moisture prevention, stable protection of the base layer: It has good permeability (permeability coefficient ≥ 1 × 10 ⁻ cm/s), can quickly divert rainwater or surface runoff, prevent water from lingering between the grade layer and the soil base layer, avoid soil base softening and bearing capacity reduction due to accumulated water, and thus prevent overall settlement of the lane; At the same time, reduce the erosion of soil base by rainwater and maintain the integrity of the base structure.

4. Durable and easy to lay, reducing construction costs: After being treated with UV resistance and acid and alkali resistance, it can withstand long-term outdoor sun and rain exposure, with a service life of 5-10 years; The texture is flexible (thickness 1-3mm), lightweight (100-300g/m ²), and can quickly fit the undulations of the ground. When laying, only simple overlapping is required (overlap width ≥ 15cm), without the need for professional equipment. It is compatible with the gravel laying process, and the construction efficiency is 40% higher than traditional sand and gravel isolation layers, with lower material costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Residential grade lane: It is laid in the private grade lane of a family residence, separating the grade lane from the soil in the courtyard to prevent soil from being carried to the grade layer when vehicles enter and exit, resulting in lane compaction. At the same time, it enhances the load-bearing capacity of the lane, adapts to the daily crushing of private cars and small trucks, and reduces potholes caused by frequent use of the lane.

2. Commercial ground level lane: A level lane used in commercial areas such as shopping malls, industrial parks, and warehouses. Through reinforcement and drainage functions, it can cope with the repeated loads of heavy vehicles such as logistics trucks and forklifts, prevent lane sinking and deformation, and quickly drain accumulated water during the rainy season to avoid muddy and slippery traffic and ensure safe passage.

3. Gravel sections of rural roads: used below the gravel paved sections of rural roads to isolate the gravel from the roadbed soil, resist the rolling of agricultural machinery, tractors and other vehicles, reduce the phenomenon of "mud flooding" caused by soil upwelling, and improve the road's resistance to rainwater erosion, reducing the frequency of rural road maintenance.

4. Gravel area of the parking lot: It is laid below the gravel laying area of the outdoor parking lot to enhance the overall structural stability of the parking lot, adapt to the load of multiple vehicles parked at the same time, prevent the gravel layer from being crushed and displaced, and divert rainwater to avoid water accumulation in the parking lot, keeping the site dry and clean.

Geotextile Fabric under Gravel Driveway focuses on the core requirements of gravel lanes, with the core advantages of "isolation and anti mixing, reinforced load-bearing, drainage and moisture resistance, durability and easy paving", accurately solving the pain points of "easy settlement, easy compaction, and difficult maintenance" of gravel lanes. Whether it is the daily use of residential private lanes or high-frequency load scenarios on commercial sites and rural roads, scientific performance design can significantly improve the structural stability and service life of grade lanes, reducing later repair costs. The product combines functionality and economy, with convenient construction and adaptability to various gravel laying processes. It is an ideal supporting material for achieving the goals of "low cost, long service life, and minimal maintenance" in gravel lane engineering, providing reliable guarantees for the efficient construction and long-term use of gravel lanes.