Geotextile Fabric Behind Retaining Wall

1. Anti filtration and loss prevention: intercepting fine particles of backfill soil, preventing loss of voids, and ensuring smooth drainage to maintain structural integrity.

2. Stress relief wall: Drain accumulated water to reduce pore water pressure, relieve lateral pressure on the soil, and reduce wall cracking and tilting.

3. Isolation and wear reduction: Separate the wall from the backfill material, prevent sharp objects from wearing the wall, and avoid material mixing affecting strength.

4. Easy to lay and adapt: Flexible and adaptable to irregular contours, easy to cut and assemble, fast to construct, compatible with multiple types of retaining walls.

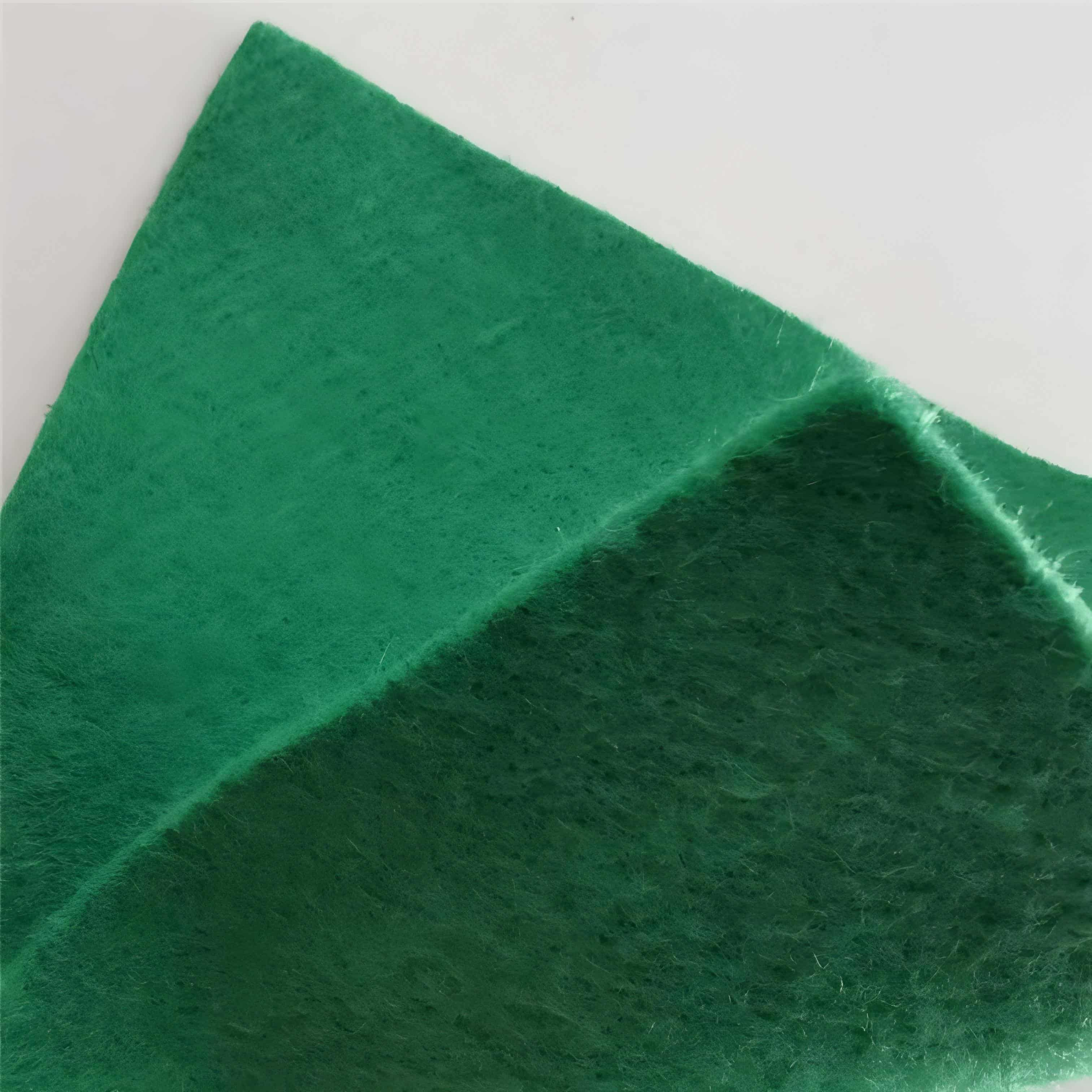

Products Introduction:

Geotextile Fabric Behind Retaining Wall is a functional geosynthetic material specially designed for retaining wall structure. It is made of polypropylene (PP) or polyester (PET) as raw materials through needle punched non-woven, woven and other processes. Some products are anti-aging, acid and alkali resistant to adapt to complex environments. Its core function is to be laid between the main body of the retaining wall and the backfill soil behind it, and to solve the problem of structural instability caused by soil erosion and excessive water pressure behind the retaining wall through the three functions of "reverse filtration and drainage, isolation and protection, and auxiliary reinforcement". It extends the service life of the retaining wall and is a key supporting material for various retaining wall projects (such as gravity type, cantilever type, and reinforced soil type).

Product Features:

1. Precise filtration to prevent soil erosion: The fabric pores are scientifically designed (0.05-0.2mm) to efficiently intercept fine particles (such as clay and silt) in the backfill soil, preventing them from seeping into the surface of the retaining wall with water flow and forming voids; At the same time, it allows for smooth drainage of moisture, avoids fine soil particles blocking drainage channels, ensures the integrity of backfill soil structure, and reduces the settlement risk of retaining walls caused by "soil loss" from the root.

2. Drainage and pressure reduction, stable retaining wall: With excellent permeability (permeability coefficient ≥ 1 × 10 ⁻ cm/s), it can quickly divert rainwater and groundwater behind the retaining wall, reduce the pore water pressure of backfill soil, avoid the increase in soil weight and strength caused by water accumulation, effectively alleviate the lateral pressure of soil on the retaining wall, reduce hidden dangers such as wall cracking and tilting, especially suitable for rainy areas or scenarios with high groundwater levels.

3. Isolation and protection to reduce material wear: It can effectively separate the main body of the retaining wall (such as concrete and stones) from the backfill material behind (such as sand and gravel, miscellaneous fill), avoiding structural damage caused by sharp crushed stones directly rubbing against the wall surface; At the same time, it prevents the mixing of backfill soil with different gradations (such as sand and clay mixing), maintains the bearing capacity of backfill soil, and extends the overall service life of retaining walls.

4. Auxiliary reinforcement, strong overall stress: High strength models (tensile strength ≥ 15kN/m) can form a "composite stress system" with backfill soil, assisting in dispersing lateral pressure on the soil, enhancing the shear resistance of the soil behind the retaining wall, especially suitable for complex scenarios such as high fill and soft soil foundation, and improving structural stability.

5. Easy to lay and adapt, reducing construction costs: with flexible texture and light weight (100-400g/m ²), it can be flexibly cut and spliced according to the contour behind the retaining wall (such as arc and line shapes), and can fit irregular base layers; No professional equipment is required for laying, and manual overlap (overlap width ≥ 10cm) can be completed. It is compatible with various retaining wall construction processes and can shorten the construction period by 20% -30% compared to traditional protective materials.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Highway subgrade engineering: It is laid between the subgrade and the pavement base to provide isolation and prevent the mixing of different soil materials from affecting structural stability. At the same time, it enhances the deformation resistance of the subgrade, reduces pavement cracking, and is suitable for new construction and maintenance projects of various levels of highways.

2. Water conservancy embankment protection: It is laid on the upstream or downstream slope of the embankment, utilizing its anti erosion and anti filtration properties to resist the erosion of water flow on the soil of the dam body, prevent the loss of fine particles, and at the same time guide the seepage of the dam body to ensure the safety of the embankment. It is suitable for reinforcing small and medium-sized reservoirs and river embankments.

3. Landfill isolation: As an anti-seepage auxiliary layer of the landfill, it is laid below or above the anti-seepage membrane to isolate the garbage from the surrounding soil, prevent the infiltration and diffusion of pollutants, and filter impurities in the leachate to protect the groundwater environment.

4. Agricultural irrigation and drainage system: It wraps around the inner walls of farmland irrigation channels or drainage ditches, filters sediment in the water flow, prevents channel blockage, protects the soil on the channel walls from erosion, extends the service life of irrigation and drainage facilities, and is suitable for farmland water conservancy renovation projects.

5. Building foundation pit drainage: Lay on the slope or bottom of the building foundation pit to quickly drain the accumulated water in the pit, reduce soil moisture content, enhance slope stability, prevent collapse, and filter fine soil particles to avoid blockage of the drainage system and ensure construction safety.

Geotextile Fabric Behind Retaining Wall focuses on the core protection scenarios behind retaining walls, with the core advantages of "anti filtration and anti loss, drainage and pressure reduction, isolation and wall protection, and easy construction", accurately solving pain points such as "structural instability, short service life, and complex construction" in retaining wall engineering. Whether it is the foundation protection of traditional gravity retaining walls or the reinforcement of high fill retaining walls in complex terrains, they can all construct reliable "protective barriers" behind the retaining walls through scientific performance design. The product combines functionality and economy, improving structural safety while reducing construction and maintenance costs. It is an ideal supporting material for ensuring long-term stability in various retaining wall projects.