What is a Geotextile Fabric? A Beginner's Guide to Functions and Types

Introduction: The Invisible Engine of Modern Construction

Beneath the roads we power on, at the back of the partitions protecting lower back hillsides, and inside the foundations of our infrastructure lies an unsung hero: geotextile fabric. Often known as a "technical textile," this permeable artificial or herbal cloth is a fundamental element in civil, environmental, and geotechnical engineering projects. At its core, a geotextile is designed to have interaction with soil and rock to beautify stability, supply protection, and enhance performance. If you've got ever questioned what offers durability to a gravel driveway or prevents erosion on a steep slope, the reply regularly entails a layer of geotextile. This information will demystify these versatile fabrics, explaining what they are, how they work, the one of a kind kinds available—including famous choices like polypropylene non woven geotextile and sustainable selections like coir geotextile—and the place they are essential.

Defining Geotextile Fabric: More Than Just Cloth

A geotextile material is a planar, permeable material fabric especially manufactured for use in contact with soil, rock, earth, or any different geotechnical material. Unlike everyday fabric, these substances are engineered with particular homes to function one or greater key mechanical, hydraulic, or protecting features in a project. They can be made from artificial polymers, such as polyester or polypropylene, or from herbal fibers like coconut, jute, or straw. The preference of cloth immediately influences its durability, strength, and suitability for special environments. For instance, a sturdy polyester geotextile cloth is regularly chosen for its excessive tensile power and resistance to creep in everlasting reinforcement applications. Understanding this engineered motive is the first step to appreciating its position as a essential geosynthetic.

The Core Functions: What Does Geotextile Fabric Do?

Geotextiles are multifunctional, however their roles can be distilled into 4 foremost functions: separation, filtration, drainage, and reinforcement.

Separation: This is one of the most frequent uses. A geotextile positioned between two varied soil layers (like gravel and gentle subgrade) prevents them from mixing. For example, in a avenue base, it maintains the mixture from sinking into the smooth soil beneath, preserving the road's structural integrity and extending its life.

Filtration: Geotextiles permit water to waft thru their airplane whilst conserving soil particles. This is indispensable in drainage applications, like at the back of a conserving wall or round a perforated pipe, the place water wishes to get away besides washing away the surrounding soil. A polypropylene non woven geotextile is regularly used right here due to its extremely good filtering characteristics.

Drainage: Some geotextiles, specially thick nonwovens, can transmit water inside their very own plane. This permits them to acquire and channel drinks or gases to an outlet, relieving pore strain and growing steadiness in embankments or at the back of structures.

Reinforcement: By introducing tensile power into a soil mass that has little to none, geotextiles act as a reinforcing element. This precept is used in steep slope reinforcement, soil conserving walls, and over very smooth ground. High-strength woven or knitted fabrics, such as a polyester geotextile fabric, excel in this characteristic due to their excessive modulus and low elongation.

A Deep Dive into Geotextile Types: Woven vs. Non-Woven

The two broadest classes are described by way of their manufacturing process, which dictates their shape and best applications.

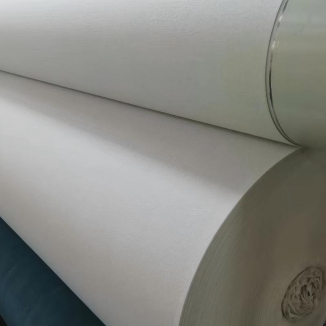

Woven Geotextiles: These are made by way of interlacing yarns or tapes on a loom, comparable to normal apparel textiles. This creates a regular, grid-like pattern. Woven geotextiles are acknowledged for their excessive tensile strength, low elongation (they do not stretch much), and tremendous load distribution. They are chiefly used for reinforcement and separation in high-stress purposes like roads, parking lots, and basis support. Monofilament and slit-film woven sorts provide one-of-a-kind balances of electricity and permeability.

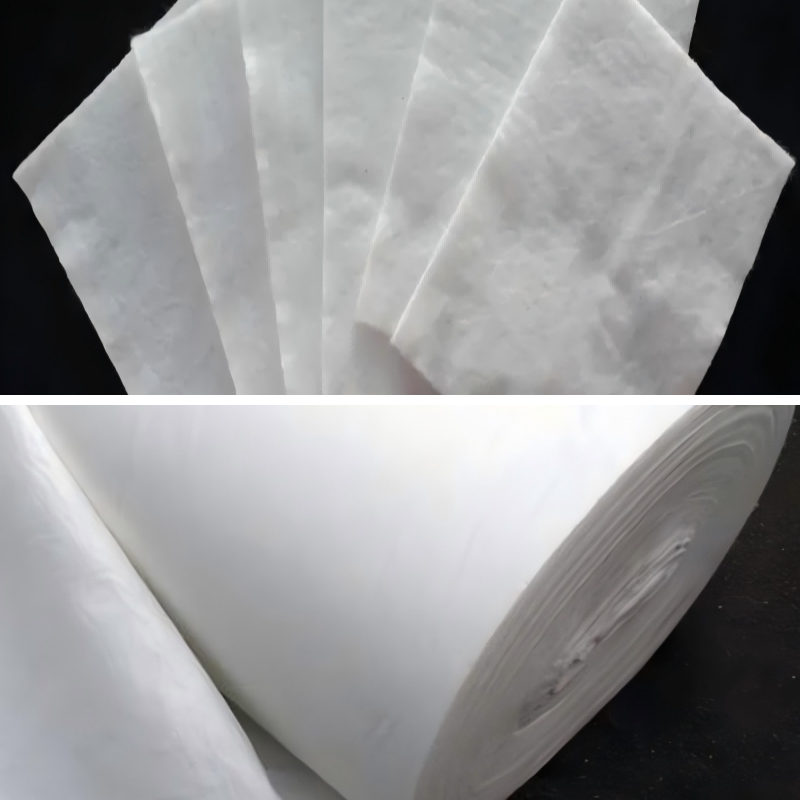

Non-Woven Geotextiles: These are made from brief or non-stop fibers that are bonded collectively via mechanical (needle-punching), thermal, or chemical means. This outcomes in a felt-like, fuzzy fabric. Needle-punched non-wovens are the most common. They are greater bendy and conformable than wovens and are valued for their filtration, drainage, and safety capabilities. The traditional polypropylene non woven geotextile is a workhorse for drainage at the back of walls, erosion manipulate below riprap, and as a protecting cushion for geomembrane liners. Their thickness additionally gives great separation.

Material Matters: From Synthetics to Naturals

The polymer or fiber kind is a key determinant of a geotextile's residences and longevity.

Polypropylene: The most frequent artificial material, in particular for non-wovens. It is lightweight, chemically resistant (particularly to acids and alkalis), and cost-effective. However, it is inclined to UV degradation if left uncovered and requires stabilization for long-term projects. A polypropylene non woven geotextile is ubiquitous in drainage and filtration roles.

Polyester: Known for ultimate tensile strength, resistance to creep (stretching beneath long-term load), and higher UV resistance than polypropylene. It is much less chemically resistant to robust alkalis. Polyester geotextile fabric, frequently in woven form, is the desired preference for everlasting reinforcement functions like steep slopes and maintaining partitions the place long-term overall performance is critical.

Natural Fiber Geotextiles: Made from biodegradable substances like coconut (coir), jute, or straw. They are used in brief erosion manage and bioengineering. A coir geotextile, for example, is ideal for slope stabilization and revegetation projects. It holds soil in area for 2-5 years—long sufficient for vegetation to set up roots—before naturally decomposing, including natural count to the soil. This makes it an eco-friendly answer for appropriate applications.

Key Applications in Construction and Engineering

Geotextiles are versatile problem-solvers throughout severa fields:

Road and Railway Construction: Used for separation and stabilization between subgrade and mixture base, lowering rutting and extending upkeep cycles.

Drainage Systems: Wrapped round French drains and mixture drains to filter soil whilst permitting water into the pipe. Non-wovens are widespread here.

Erosion Control: On slopes, channels, and shorelines, geotextiles stabilize soil till vegetation grows. They are used beneath riprap (stone armor) or in the shape of biodegradable rolls like coir geotextile blankets.

Retaining Walls and Slopes: Provide reinforcement and drainage at the back of constructions to enhance steadiness and forestall water strain buildup. A high-strength polyester geotextile material is regularly distinctive for reinforcement layers in automatically stabilized earth (MSE) walls.

Landfill and Containment: Used as a protecting cushion and drainage layer for geomembrane liners in landfills, ponds, and mining operations.

Selection and Installation: Critical Considerations

Choosing the proper geotextile is no longer generic; it requires engineering judgment. Key specification residences include:

Grab Tensile Strength: Resistance to pulling force.

Elongation: How tons it stretches earlier than breaking.

Permittivity: The potential to enable water drift via its aircraft (filtration).

Apparent Opening Size (AOS): The high-quality pore dimension that controls soil retention.

UV Resistance: Critical if the cloth will be uncovered for greater than a brief period.

Installation is equally important. The subgrade should be proper prepared—smooth, compacted, and free of debris. The material have to be positioned barring immoderate wrinkles, with enough overlap (typically 12 to 36 inches) between rolls, and without delay blanketed with fill cloth to forestall UV harm and displacement. Proper set up ensures the polypropylene non woven geotextile or different chosen material performs its meant characteristic for the format existence of the project.

Conclusion: The Foundational Fabric for a Stable Future

From stabilizing a residential driveway to securing the basis of a big dam, geotextile fabric are a foundational issue of modern, resilient construction. They grant elegant, low cost options to age-old engineering troubles like soil instability, erosion, and bad drainage. By appreciation the awesome functions—separation, filtration, drainage, reinforcement—and the one of a kind types, from high-strength polyester geotextile cloth to the eco-friendly coir geotextile, you can admire their fundamental role. Whether you are a contractor, engineer, or DIY enthusiast, specifying the right geotextile is a choice that immediately affects the longevity, safety, and success of your project. When in doubt, seek advice from with a geotechnical engineer or official dealer to make certain you choose the proper cloth for the job, making sure your work stands on stable ground.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province