Seaming HDPE Geomembranes: Extrusion vs. Wedge Welding Techniques

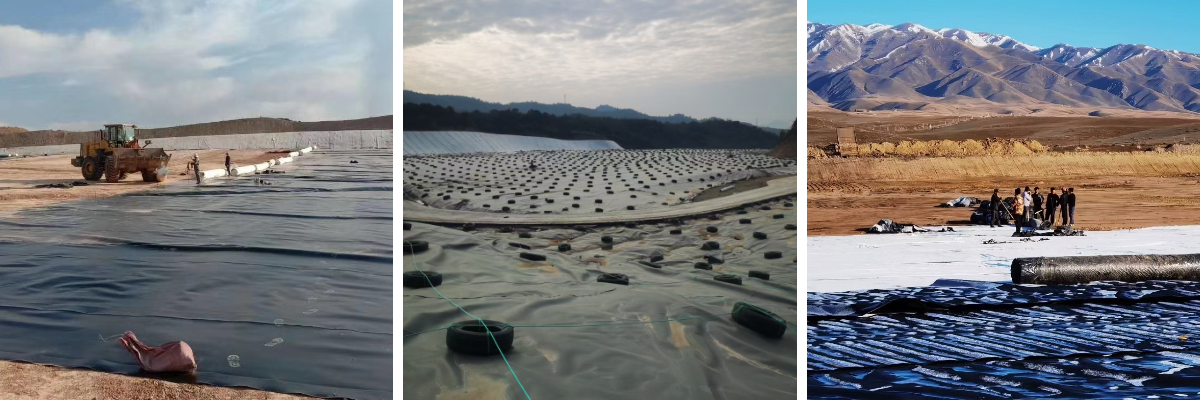

The overall performance of an hdpe geomembrane—a cornerstone of containment structures for landfills, water reservoirs, wastewater facilities, and mining sites—depends totally on seam integrity. A vulnerable or poorly sealed seam can undermine the whole system, inflicting leaks, environmental harm, and steeply-priced repairs. Two main welding strategies dominate hdpe geomembrane seaming: extrusion welding and wedge welding. Each has wonderful strengths, uses, and requirements, so deciding on the proper one hinges on task important points like geomembrane thickness, website online conditions, and overall performance needs. This information compares each techniques, breaking down their processes, pros, cons, and perfect applications, whilst emphasizing the function of a nice hdpe geomembrane welding laptop in growing a dependable impermeable geomembrane.

Why Seams Are Make-or-Break for HDPE Geomembrane Performance

HDPE geomembrane is prized for its brilliant impermeability, durability, and chemical resistance—traits that make it the pinnacle desire for containment. But even the highest-grade geomembrane fails if seams aren’t right welded. Seams are the most inclined components of any containment system, as they join character rolls into a single, non-stop barrier. A well-welded seam ought to healthy or exceed the geomembrane’s strength, making sure no liquid or fuel leakage. This is the place welding approach and hdpe geomembrane welding desktop fine emerge as critical. Whether for a landfill liner, irrigation pond, or industrial tank, the purpose is usually a seamless impermeable geomembrane that meets strict rules and lasts for decades.

Wedge Welding: The Go-To for Standard HDPE Seaming

Wedge welding (or hot wedge welding) is the most frequent hdpe geomembrane seaming technique, liked for its speed, efficiency, and suitability for most every day applications. It makes use of an hdpe geomembrane welding computer with a heated wedge to soften overlapping geomembrane edges, then strain rollers compress the molten fabric to shape a molecular bond as it cools.

The Wedge Welding Process

Preparation: Clean overlapping edges (typically 15–30 cm) to take away dirt, debris, or moisture—contaminants that weaken seams. Secure the hdpe geomembrane flat to stop motion at some point of welding.

Heating: Heat the machine’s warm wedge to the most reliable temperature (calibrated for geomembrane thickness and density). Position the wedge between overlapping layers to soften internal surfaces.

Compression: As the laptop strikes alongside the seam, stress rollers at the back of the wedge press molten layers together, removing air pockets for full fusion.

Cooling: The seam cools quickly, forming a strong, uniform bond. Test the cooled seam to affirm leak resistance.

Advantages of Wedge Welding

Speed & Efficiency: Machines function at steady speeds, making them best for large-scale initiatives the place time is key.

Cost-Effective: Equipment is greater inexpensive than extrusion welders, and operators want much less training.

Standard Thickness Suitability: Works especially nicely for geomembranes 0.5–2.0 mm thick—the most frequent vary for residential, commercial, and industrial use.

Reliable: Properly executed, it produces constant seams that meet or exceed enterprise requirements for energy and impermeability.

Limitations of Wedge Welding

Thickness Limits: Less wonderful for hdpe geomembrane over two mm thick, as the wedge may additionally no longer utterly soften the cloth via its depth.

Contour Challenges: Best for straight seams; slight curves work, however complicated shapes or tight corners may also want hand welding or choice methods.

Surface Sensitivity: Uneven surfaces or wrinkles can purpose uneven melting/compression, weakening seams.

Extrusion Welding: Heavy-Duty Seaming for Critical Applications

Extrusion welding is a specialised approach for thick hdpe geomembrane, seam repairs, or high-stress joints (e.g., pipes, corners, penetrations). Unlike wedge welding, which melts the geomembrane itself, it makes use of an hdpe geomembrane welding computing device to extrude a molten bead of virgin HDPE resin into the joint. This bead fuses with heated geomembrane edges, growing a bolstered seam.

The Extrusion Welding Process

1. Preparation: Clean the joint location and bevel geomembrane edges to create a V-shaped groove for the extruded bead—maximizing contact between resin and geomembrane.

2.Heating: Heat HDPE resin to its melting factor and extrude it as a non-stop bead. Simultaneously, warmness geomembrane edges to make certain fusion with the bead.

3.Application: Guide the computing device alongside the joint, depositing the bead into the groove. Use a curler to compress the bead, filling the groove and bonding tightly.

4.Curing: The bead cools and hardens, forming a thick, stress-resistant seam.

Advantages of Extrusion Welding

Thick Geomembrane Strength: Preferred for hdpe geomembrane over two mm thick, as the bead ensures full fusion via the material.

Versatility: Ideal for complicated joints, corners, pipe penetrations, and repairs. Can weld multiple geomembrane thicknesses.

Enhanced Durability: The extruded bead provides material, making seams extra resistant to abrasion, punctures, and environmental stress.

Critical Application Reliability: For high-risk initiatives (landfill closing covers, hazardous waste containment), it presents greater protection for the impermeable geomembrane.

Limitations of Extrusion Welding

Slower Speed: More labor-intensive than wedge welding, making it much less environment friendly for large, straight seams.

Higher Cost: Machines are pricier, and operators want specialised training.

Material Waste: Uses extra HDPE resin for the bead, growing fabric costs.

Choosing Between Extrusion and Wedge Welding

The proper method relies upon on 4 key factors:

1. HDPE Geomembrane Thickness

Wedge welding is great for 0.5–2.0 mm thicknesses. Extrusion welding is encouraged for over two mm or integral joints in thinner geomembranes.

2. Project Risk Level

Low-risk initiatives (residential irrigation ponds) use wedge welding. High-risk tasks (hazardous waste containment) want extrusion welding for integral seams.

3. Seam Geometry

Straight, large-area seams go well with wedge welding. Complex shapes, corners, or repairs require extrusion welding’s versatility.

4. Budget & Timeline

Prioritize velocity and cost? Choose wedge welding. Need most energy and durability? Opt for extrusion welding.

The Role of Quality HDPE Geomembrane Welding Machines

No remember the technique, the hdpe geomembrane welding computer dictates seam quality. A gorgeous computing device presents unique temperature control, regular pressure, and steady speed—essential for uniform, robust seams. Wedge welding machines want adjustable heat/pressure for one-of-a-kind thicknesses; extrusion welders want dependable resin feeding and temperature regulation. Pairing a reliable computing device with educated operators ensures an impermeable geomembrane that meets policies and mission needs.

Conclusion: Select the Right Seaming Technique

Both extrusion and wedge welding play fundamental roles in hdpe geomembrane seaming. Wedge welding excels at velocity and price for trendy projects, whilst extrusion welding grants energy for thick geomembranes and integral applications. By aligning approach preference with thickness, risk, geometry, and budget—and investing in a pleasant hdpe geomembrane welding machine—you’ll acquire a durable, impermeable geomembrane that protects your task and the surroundings for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province