HDPE Geocell for Road Base Reinforcement: Stabilizing Weak Soils & Reducing Rutting

Weak soil foundations and rutting are two of the most power challenges in avenue building and maintenance. Roads constructed on gentle or unstable soils frequently go through from uneven settlement, cracking, and untimely failure, whilst rutting—caused by way of repeated heavy car loads—compromises security and requires widely wide-spread repairs. Traditional options like over-excavation and substitute with gravel or concrete are costly, time-consuming, and environmentally unfriendly. Enter HDPE Geocell: a modern geosynthetic cloth that transforms avenue base reinforcement by way of improving soil balance and resisting rutting. This article explores 4 key methods HDPE Geocell elevates street performance, explaining why geocell technological know-how has grow to be a staple for engineers and contractors worldwide.

1. Superior Material & Structural Advantages: The Foundation of Road Base Stability

The effectiveness of HDPE Geocell in street base reinforcement begins with its excellent fabric composition and modern cell structure. HDPE (High-Density Polyethylene) is a sturdy thermoplastic famend for its strength, durability, and resistance to environmental stress—qualities that make it perfect for geosynthetic applications. Unlike low-grade geosynthetics that degrade quickly, HDPE Geocell is engineered to stand up to harsh conditions, together with severe temperatures, chemical erosion from soil contaminants, and UV radiation.

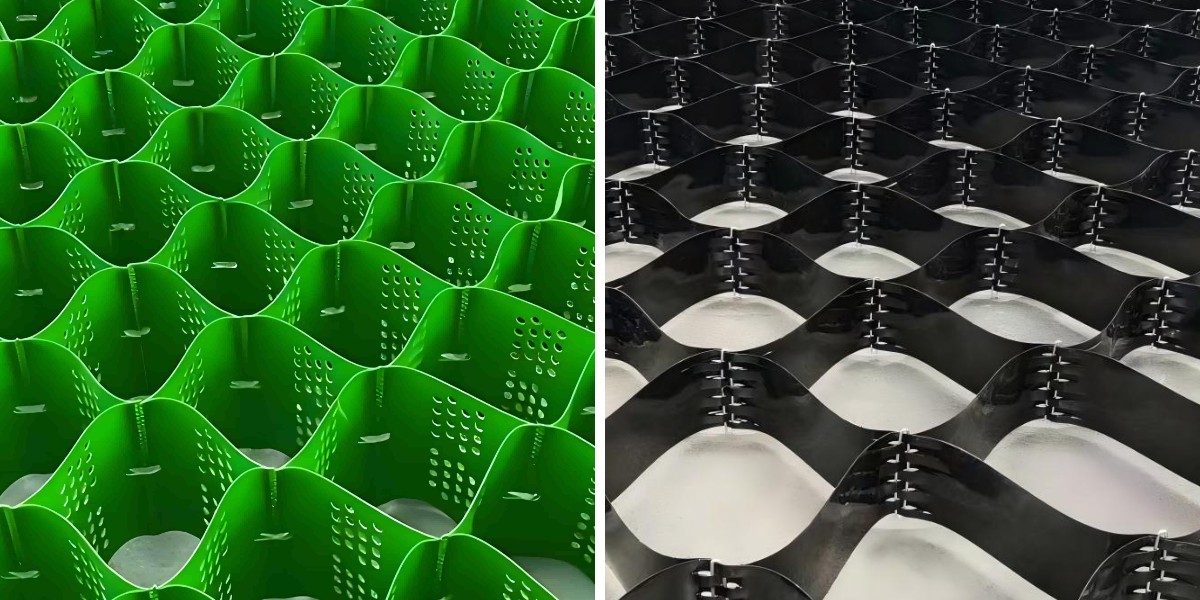

The defining feature of HDPE Geocell is its honeycomb-like mobile structure. When expanded, the geocell types a 3D grid of interconnected cells that can be stuffed with neighborhood soil, gravel, sand, or recycled aggregates. This shape creates a rigid, load-distributing platform that anchors the street base to the underlying soil. HDPE Geocell normally has a tensile energy of 20-30 MPa and a carrier lifestyles of 50+ years, some distance exceeding typical reinforcement substances like woven geotextiles. Its flexibility when unexpanded and tension when stuffed make it adaptable to various terrain whilst retaining structural integrity.

Another key gain is its light-weight design. HDPE Geocell rolls are convenient to transport and handle, decreasing logistics expenses in contrast to heavy gravel or concrete. A single roll of HDPE Geocell can cowl up to one hundred rectangular meters when expanded, making it environment friendly for large-scale street projects. This mixture of strength, durability, and practicality units the stage for its notable overall performance in avenue base reinforcement.

2. Stabilizing Weak Soils: Preventing Settlement & Cracking

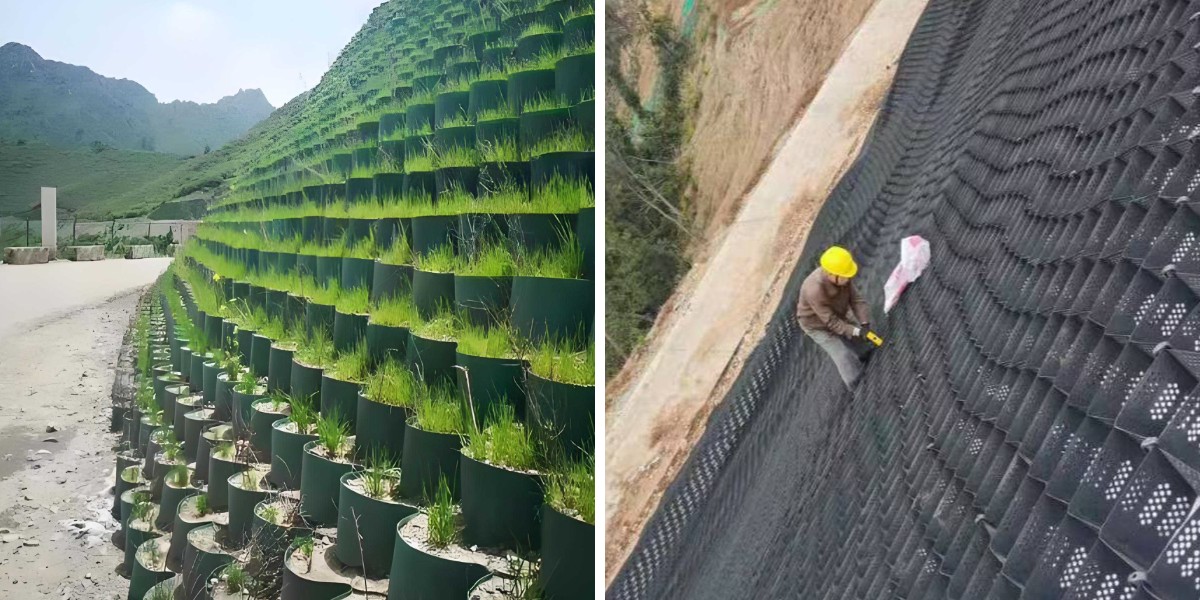

Weak soils—such as clay, silt, or natural soils—have low bearing capacity, making them inclined to agreement beneath street loads. HDPE Geocell addresses this with the aid of developing a strengthened composite layer that distributes hundreds evenly and restricts soil movement. This mechanism is some distance greater high quality than standard methods, which frequently solely masks soil weaknesses alternatively than resolving them.

When established in the avenue base, HDPE Geocell’s mobile shape acts as a "soil confinement system." The cells lure and compact the infill cloth (e.g., nearby gravel), stopping lateral motion and spreading of the soil. This confinement will increase the bearing potential of the susceptible soil by means of 300-500%, in accordance to geotechnical engineering studies. For example, a street constructed on clay soil with HDPE Geocell reinforcement experiences much less than 5mm of agreement over 10 years, in contrast to 25mm+ for unreinforced roads.

HDPE Geocell additionally minimizes differential settlement, a frequent purpose of avenue cracking. By growing a uniform load-bearing layer, it ensures that heavy automobile masses are dispensed throughout a wider area, lowering stress on localized soil patches. This is in particular treasured in areas with variable soil conditions, the place unreinforced roads frequently advance cracks and potholes. Contractors working on rural roads in vulnerable soil areas document that geocell reinforcement eliminates the want for costly soil replacement, reducing fabric charges by means of 40%.

3. Reducing Rutting: Enhancing Load Resistance & Longevity

Rutting—permanent indentations in the avenue surface—costs governments and contractors billions annually in repairs. It is brought on by means of repeated shear stress from heavy trucks, in particular on roads with insufficient base reinforcement. HDPE Geocell combats rutting via strengthening the avenue base’s resistance to shear forces and preserving structural integrity underneath non-stop load.

The 3D mobile shape of HDPE Geocell acts as a inflexible framework that absorbs and distributes shear stress. When a heavy truck passes over, the geocell transfers the load from the floor layer to the underlying soil, decreasing the stress on the street base by using up to 60%. This prevents the base cloth from transferring and compacting into ruts. Field checks on highways with excessive truck site visitors exhibit that HDPE Geocell-reinforced roads boost rut depths of much less than 2mm after five years, in contrast to 15mm+ for unreinforced roads.

HDPE Geocell additionally enhances the sturdiness of the avenue floor by way of stabilizing the base. A steady base prevents the floor asphalt or concrete from cracking, which can speed up rutting by way of permitting water infiltration. In areas with heavy rainfall, this water resistance is critical—unreinforced street bases regularly grow to be waterlogged, dropping energy and growing ruts quickly. Geocell’s confinement of the base fabric continues it dry and stable, even in moist conditions, extending the road’s carrier existence via 2-3 times.

4. Easy Construction & Cost-Effectiveness: Delivering Value Across Projects

Beyond performance, HDPE Geocell stands out for its ease of set up and long-term cost-effectiveness—key elements for contractors and challenge managers working inside tight budgets and timelines. Unlike regular reinforcement techniques that require heavy equipment and professional labor, geocell set up is simple and efficient.

The set up technique includes three easy steps: getting ready the subgrade (clearing particles and leveling), increasing the HDPE Geocell rolls and securing them with anchors, and filling the cells with infill cloth (local aggregates are frequently sufficient). A crew of 3-4 employees can set up five hundred rectangular meters of HDPE Geocell per day, in contrast to 100-150 rectangular meters for concrete reinforcement. This reduces development time through 30-50%, minimizing visitors disruptions for avenue improvements and new builds.

Cost financial savings are big throughout the assignment lifecycle. Upfront, HDPE Geocell eliminates the want for costly soil excavation and imported gravel, reducing cloth expenses through 20-40%. Long-term, its sturdiness reduces preservation costs—geocell-reinforced roads require 70% fewer rutting repairs and resurfacing in contrast to unreinforced roads. A case find out about of a municipal avenue task in Europe observed that HDPE Geocell reinforcement decreased whole task prices by using 25% over 10 years, inclusive of preliminary development and maintenance.

Conclusion: HDPE Geocell—The Future of Road Base Reinforcement

For engineers, contractors, and municipal managers tasked with constructing durable, low in cost roads on susceptible soils, HDPE Geocell provides an unbeatable solution. Its optimal cloth and structural plan grant a secure foundation, its soil confinement mechanism eliminates contract and cracking, its 3D shape resists rutting, and its effortless set up offers giant price savings. Whether developing rural roads on clay soils, upgrading city highways with heavy traffic, or repairing rut-prone roads, geocell technological know-how persistently outperforms usual methods.

As infrastructure budgets tighten and the demand for long-lasting roads grows, HDPE Geocell is no longer an revolutionary option—it’s a realistic necessity. By selecting HDPE Geocell for your subsequent avenue base reinforcement project, you’ll construct roads that face up to susceptible soils, face up to rutting, and supply cost for decades. Make the swap to HDPE Geocell and increase your avenue development requirements today.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province