Using Geotube for Mining Tailings and Mineral Slurry Management.

Introduction: The Mounting Challenge of Mining Tailings

The international mining enterprise faces a defining mission of the twenty first century: the accountable administration of tailings. For each and every ton of ore processed, enormous portions of water-saturated mineral slurry and fine-grained waste are generated. Traditional storage in large, moist impoundments poses vast environmental, safety, and economic risks, inclusive of conceivable dam disasters and long-term liability. In this context, dewatering and solidification have turn out to be paramount objectives. Advanced Geotube dewatering technology, utilising high-strength dewatering baggage for sludge, affords a transformative, engineering-led strategy to changing liquid tailings into stable, manageable solids, essentially altering the paradigm of mine waste management.

The Geotube Dewatering Process: From Slurry to Solid

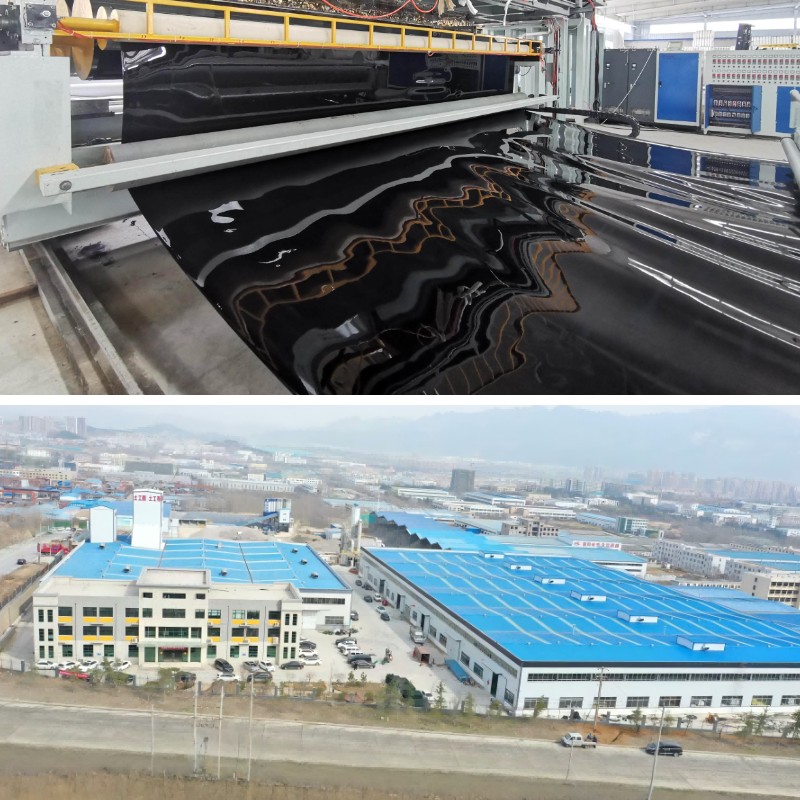

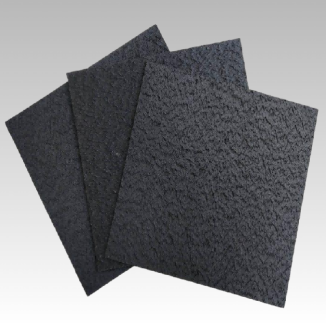

A Geotube container is a large, engineered sediment filter bag made from high-performance, permeable geotextiles. The dewatering procedure is a continuous, bodily separation technique that is each stylish and surprisingly effective.

Conditioning and Pumping: Mining tailings slurry is first combined with polymeric flocculants. This essential step reasons the ultrafine particles to clump collectively into large aggregates or "flocs." These flocs are imperative for environment friendly dewatering as they forestall the first-class particles from blinding the pores of the sediment filter bag.

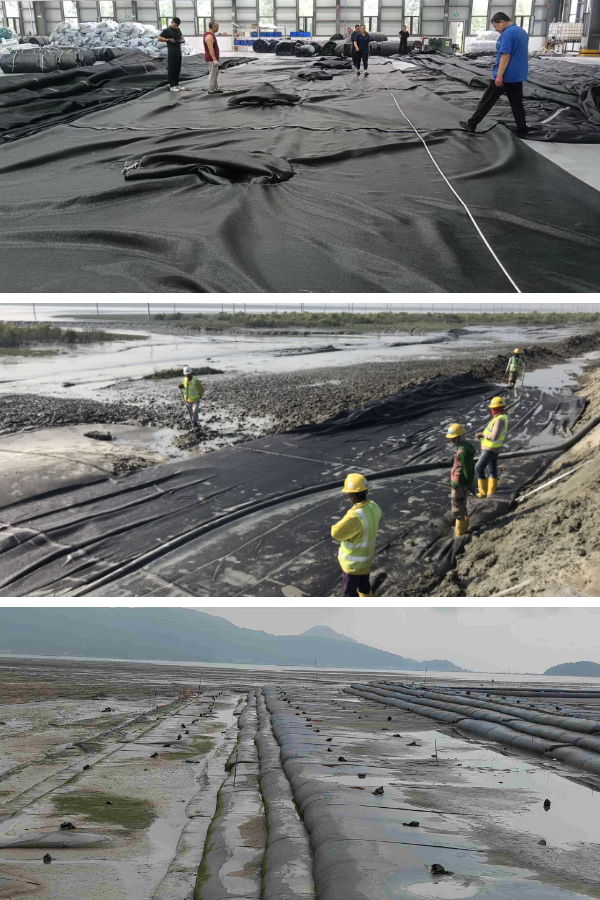

Filling and Filtration: The conditioned slurry is pumped into the dewatering luggage for sludge. As the containers fill, hydrostatic strain forces the technique water to exude thru the geotextile's tiny pores. The specifically engineered cloth acts as a particular filter, preserving the strong flocs inner whilst releasing clarified effluent.

Consolidation and Curing: Once the filling cycle for a specific unit is complete, the contained solids proceed to densify beneath their very own weight. Further dewatering happens thru consolidation, regularly aided through the addition of extra layers on top. The remaining end result is a full-size quantity reduction, frequently by way of 50-90%, yielding a stackable, stable cake with a excessive solids content material that can be safely stored, reclaimed, or used in mine closure landscaping.

Key Applications in Mining and Mineral Processing

The versatility of this science makes it appropriate for a couple of indispensable functions inside a mining operation.

1. Tailings Dewatering and Dry Stacking

This is the most impactful application. Instead of pumping slurry to an impoundment, mines can dewater tailings continually the usage of a battery of dewatering luggage for sludge. The dewatered, strong cloth can then be transported through conveyor or truck to a "dry stack" facility. This technique significantly reduces the footprint of tailings storage, eliminates the want for giant dams and their related risks, and allows innovative rehabilitation.

2. Process Water Recovery and Reuse

In water-scarce regions, each drop counts. The effluent launched from the sediment filter bag is generally very clear and can be at once recirculated lower back into the processing plant. This closed-loop machine minimizes freshwater intake, reduces the quantity of water requiring therapy in settling ponds, and helps sustainable water stewardship goals.

3. Sediment Control for Runoff and Spill Containment

Silt luggage for dewatering are used in smaller-scale however integral environmental safety roles. They are deployed in silt traps, round drainage outlets, or as emergency boundaries to seize and dewater sediment-laden runoff from stockpiles or roads, making sure compliance with water discharge guidelines and stopping environmental contamination.

Strategic Advantages Over Conventional Tailings Management

Adopting a Geotube-based dewatering method provides mining corporations compelling benefits that tackle core operational and environmental risks.

Enhanced Safety and Risk Reduction: By transferring away from moist slurry storage to dewatered, strong stacks, the catastrophic hazard related with typical tailings dam screw ups is surely eliminated. This represents a quintessential enchancment in operational protection and social license to operate.

Significant Lifecycle Cost Savings: While requiring upfront capital for the dewatering system, the long-term financial savings are substantial. Costs associated to dam construction, maintenance, monitoring, and long-term legal responsibility insurance plan are dramatically reduced. The discount in storage footprint and less complicated closure requirements additionally make a contribution to decrease lifecycle costs.

Environmental Compliance and Closure Readiness: Dewatered tailings are greater geotechnically secure and much less inclined to acid mine drainage (AMD) technology due to constrained water and oxygen infiltration. This balance simplifies ultimate mine closure and capping, main to a greater predictable and sustainable post-mining landscape. The use of silt baggage for dewatering for website online runoff manage similarly demonstrates proactive environmental management.

Operational Flexibility and Scalability: A Geotube dewatering device is modular. Capacity can be without problems scaled up or down via including or eliminating dewatering luggage for sludge. This flexibility is perfect for mines with various manufacturing costs or for specific, momentary dewatering projects, such as cleansing out a settling pond.

Critical Considerations for Successful Implementation

Success hinges on extra than simply buying the sediment filter bags. Key elements include:

Site-Specific Testing: Bench-scale and pilot-scale trying out of the tailings cloth is non-negotiable. Tests decide the most suitable polymer kind and dosage, anticipated dewatering rates, last solids content, and effluent quality.

Geotextile Selection: The material should have the right pore dimension to hold fantastic particles whilst permitting fast water release. Its tensile and seam power have to stand up to the excessive pressures of filling and the abrasive nature of mineral solids.

Integrated System Design: The device have to be designed as a whole, which includes slurry feed, polymer make-down units, pumping infrastructure, and the format of the dewatering place with appropriate lining and effluent collection.

Conclusion: Pioneering a Sustainable Future for Mining

The administration of tailings is present process a imperative and profound transformation. Geotube dewatering technology, via the use of strong dewatering baggage for sludge, affords a practical, efficient, and safer pathway forward. It transforms tailings from a eternally managed liquid legal responsibility into a stabilized strong resource, enabling water recovery, decreasing environmental footprints, and essentially enhancing chance profiles.

For forward-thinking mining companies, investing in this technological know-how is no longer in basic terms an operational decision; it is a strategic dedication to accountable aid extraction, long-term monetary stability, and sustainable closure. By integrating structures ranging from large-scale tailings dewatering to focused silt luggage for dewatering, the mining enterprise can construct a extra resilient and environmentally sound future.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province