Common Geomat Installation Mistakes & How to Avoid Them

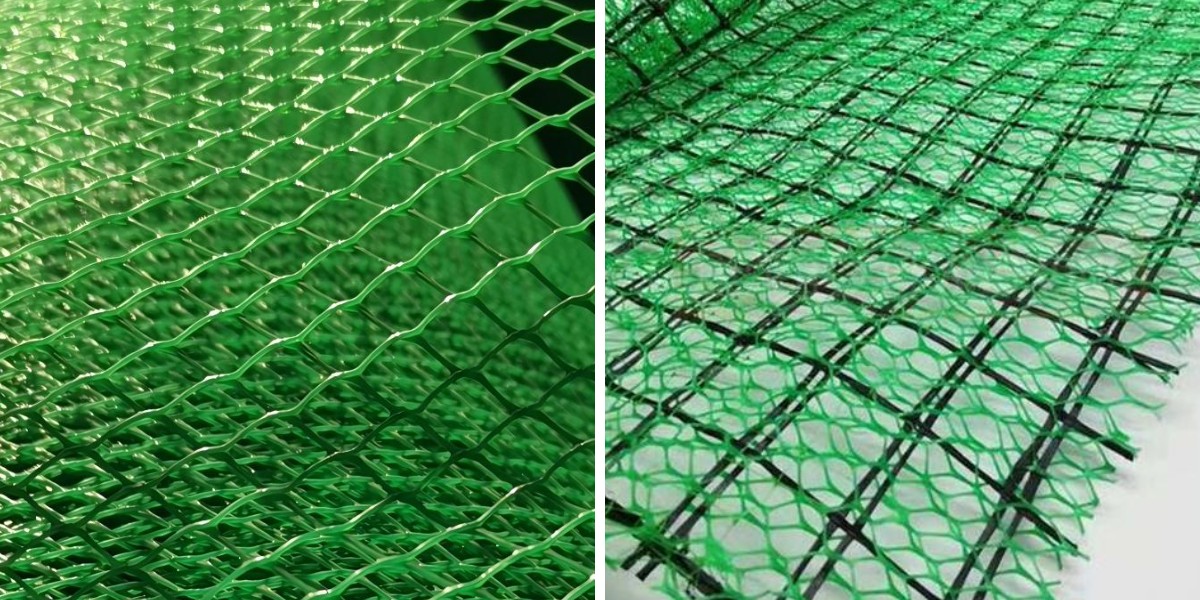

Geomat, specially 3D geonet, has end up a cornerstone in geosynthetic engineering for erosion control, drainage, and soil stabilization. Its special 3D shape and long lasting fabric supply tremendous performance—when set up correctly. However, even skilled contractors regularly fall prey to avoidable set up errors that compromise geomat’s effectiveness, main to task delays, extended costs, and untimely failure. This article highlights 4 frequent geomat set up errors, explains their consequences, and affords actionable options to make certain your 3D geonet or geomat challenge achieves superior results.

1. Inadequate Subgrade Preparation: Undermining the Foundation

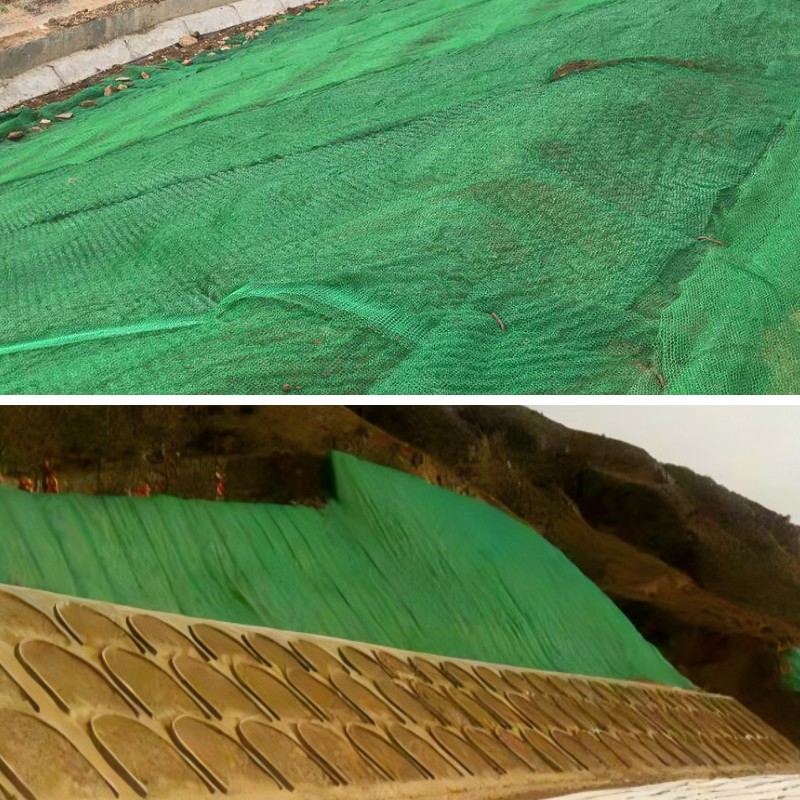

One of the most established and adverse errors is neglecting suited subgrade practise earlier than laying geomat. Many groups rush to set up geomat on unprocessed soil, unaware that uneven, unstable, or debris-covered surfaces immediately sabotage the material’s performance. For 3D geonet specifically, its honeycomb-like 3D shape depends on a flat, compacted base to distribute masses evenly and preserve drainage efficiency.

Consequences of bad subgrade instruction encompass geomat punctures from rocks or roots, uneven stress distribution that reasons tearing, and blocked drainage channels in 3D geonet. A toll road slope stabilization venture in the Midwest, for example, failed inside 6 months due to the fact contractors laid geomat over unremoved tree stumps—roots punctured the material, main to soil erosion and slope slippage. The restore fee 3x the preliminary set up budget.

How to keep away from it: Prioritize three key subgrade steps. First, clear all particles (rocks, roots, development waste) and degree uneven areas with a grader. Second, compact the subgrade to a minimal 95% compaction rate—use a vibratory curler for giant areas or a hand tamper for tight spaces. Third, tackle drainage: for 3D geonet projects, make certain the subgrade has a mild slope (1-2%) to redirect extra water. A well-prepared subgrade extends geomat’s provider lifestyles via 50% or more.

2. Incorrect Laying & Overlapping: Creating Weak Zones

Geomat’s effectiveness relies upon on non-stop coverage—gaps or inadequate overlapping between geomat rolls creates vulnerable zones the place erosion, water infiltration, or soil motion can occur. This mistake is especially frequent with 3D geonet, as its inflexible accelerated shape makes contractors overconfident in "close enough" placement, ignoring producer overlap guidelines.

Common laying mistakes encompass overlapping geomat with the aid of much less than 150mm (the enterprise standard), stretching the cloth too tightly (causing anxiety cracks) or laying it loosely (creating wrinkles that lure water), and misaligning 3D geonet’s drainage channels. A residential drainage venture suffered essential flooding due to the fact 3D geonet rolls had been overlapped with the aid of solely 50mm—heavy rainwater seeped via gaps, saturating the underlying soil and inflicting basis damage.

How to keep away from it: Follow producer specs strictly. For most geomat types, hold a 150-200mm overlap between rolls; for 3D geonet used in high-water areas, expand overlap to 250mm. Use chalk traces to mark placement earlier than laying, making sure straight alignment and steady overlap. Avoid overstretching—unroll geomat gently and enable moderate slack to accommodate temperature changes. Secure overlaps with geotextile tape or anchor pins to forestall transferring in the course of infill placement.

3. Improper Securement: Letting Geomat Shift & Fail

Geomat, in particular 3D geonet, faces regular stress from soil pressure, water flow, and environmental factors. Failing to tightly closed it true leads to shifting, lifting, or detachment—undermining its stabilization and drainage functions. This mistake is rampant on slopes or uneven terrain, the place contractors underestimate the pressure of gravity and water runoff.

Improper securement consists of the use of inadequate anchor pins, putting pins too some distance apart, or ignoring side securing. On a 30-degree slope erosion manipulate project, contractors used 150mm anchor pins spaced two meters aside for geomat—within weeks, heavy rain washed away topsoil, and the geomat lifted at the edges, exposing naked soil. The right method would have used 300mm pins spaced 1 meter apart, with extra facet trenching.

How to keep away from it: Tailor securement to terrain and geomat type. For flat areas, use 150-200mm anchor pins spaced 1.5-2 meters apart. For slopes steeper than 20 degrees, improve to 300-400mm galvanized pins spaced 1 meter apart, and add a trench (150mm deep) alongside the pinnacle aspect to bury and anchor the geomat. For 3D geonet in drainage applications, tightly closed joints with stainless metal clips in addition to pins to preserve channel alignment. Always take a look at securement by means of pulling gently on geomat edges—no motion need to occur.

4. Neglecting Post-Installation Inspection & Maintenance

Many groups deal with geomat set up as a "set-it-and-forget-it" task, skipping post-installation inspections and ongoing maintenance. This oversight approves small troubles (like minor tears or blocked drains) to amplify into foremost failures. 3D geonet is specifically susceptible here, as its drainage channels can grow to be clogged with sediment or particles if now not checked regularly.

Consequences encompass clogged 3D geonet drainage channels main to waterlogging, unaddressed tears increasing into giant gaps, and UV degradation of uncovered geomat edges. A municipal park’s erosion manipulate device failed after two years due to the fact contractors didn’t check out the 3D geonet—leaves and sediment clogged its channels, inflicting water to pool and wash away the geomat’s infill material.

How to keep away from it: Implement a structured upkeep plan. Conduct a full inspection 24 hours after installation—check for shifts, free pins, and overlap gaps. Inspect once more after the first heavy rain or storm to take a look at drainage and securement. For ongoing maintenance, time table quarterly checks: clear 3D geonet channels of debris, restore small tears with geotextile patches, and change broken anchor pins. For geomat uncovered to direct sunlight, follow UV protectant each and every 3-5 years to lengthen durability.

Conclusion: Get Geomat Installation Right for Long-Lasting Results

Geomat and 3D geonet are effective equipment for erosion control, drainage, and soil stabilization—but their overall performance hinges on right installation. By fending off these 4 frequent mistakes—poor subgrade preparation, fallacious laying/overlapping, mistaken securement, and neglecting maintenance—you’ll make certain your task provides most durability, cost-effectiveness, and performance.

Whether you’re working on a motorway slope, residential drainage system, or business development site, prioritizing appropriate set up methods protects your funding and avoids expensive repairs. For complicated projects, seek advice from with geosynthetic specialists to tailor set up to your precise terrain and geomat type. With the proper approach, your geomat or 3D geonet set up will stand the check of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province