Geotextile for Soakaway

1. Efficient Water Infiltration: Uniform pores quickly channel rainwater into the ground, preventing water accumulation and improving soakaway drainage efficiency.

2. Filtration and Anti-clogging: Intercepts fine soil particles, preventing blockage of infiltration channels and maintaining long-term drainage.

3. Corrosion Resistance and Durability: Acid, alkali, and biodegradable, it adapts to humid underground environments and extends the life of the soakaway.

4. Easy Installation and Adaptability: Lightweight and flexible, it conforms to irregular seepage areas and is easy to cut, simplifying installation and reducing installation costs.

Products Introduction:

Geotextile for Soakaway (Geotextile for Infiltration Systems) is a functional geosynthetic designed specifically for subsurface infiltration systems (Soakaway). Made from polypropylene (PP) or polyester (PET) filaments, it is needle-punched and non-woven. Some products are treated for biodegradability and acid and alkali resistance. Its core function is to be laid between the filler (such as gravel and pebbles) and the surrounding soil in infiltration pits and trenches. By providing the dual functions of "efficient water infiltration + precise filtration," it addresses the critical issue of soil particles blocking the infiltration channels and reducing drainage efficiency in infiltration systems. It ensures that rainwater, surface water, or light sewage can quickly infiltrate the ground, while protecting the infiltration filler layer from contamination by the surrounding soil. It is a core supporting material for maintaining the long-term stable operation of infiltration systems.

Product Features:

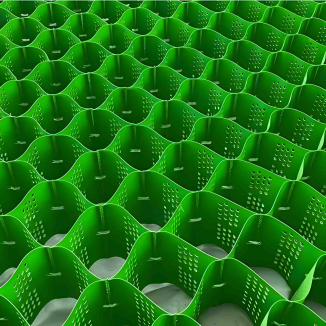

1. Multi-dimensional reinforcement to prevent slip and collapse: The geogrid's directional reinforcement (longitudinal and transverse tensile strength of 20-100 kN/m) forms a composite structure with the soil, enhancing slope shear resistance, distributing the soil's own weight and external loads, and effectively preventing slope slip and collapse. Combined with the geonet's three-dimensional structure, it further strengthens the integrity of the surface soil and reduces the risk of localized instability.

2. Anti-scouring and water filtration, erosion control and soil conservation: The geotextile layer provides precise filtration (pore size 0.1-0.5 mm), filtering fine soil particles carried by rainwater and preventing soil erosion. It also allows water to penetrate and drain, preventing surface water from softening the soil. It can withstand erosion at speeds of 3-5 m/s, and its erosion protection is 3-5 times that of traditional sandbags.

3. Ecological compatibility and synergistic restoration: The materials themselves (such as biodegradable geotextiles and eco-grids) are environmentally friendly and provide a support for grass seeds and shrubs to attach and grow. Later, vegetation roots penetrate the materials and intertwine with the soil, forming a "plant-geotextile" composite protective layer. This not only enhances protection but also restores the slope's ecological landscape, resolving the "ecological fragmentation" problem associated with traditional hard protection.

4. Flexible adaptability and efficient construction: Lightweight (50-300g per square meter), it can be cut and spliced to suit slope gradients (0-60°) and topography (convex, concave, or zigzag), eliminating the need for large equipment. The modular design supports "one layer of protection + multiple layers of reinforcement," adapting to various needs, from temporary rescue to permanent protection. Construction efficiency is over 50% higher than mortar masonry.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

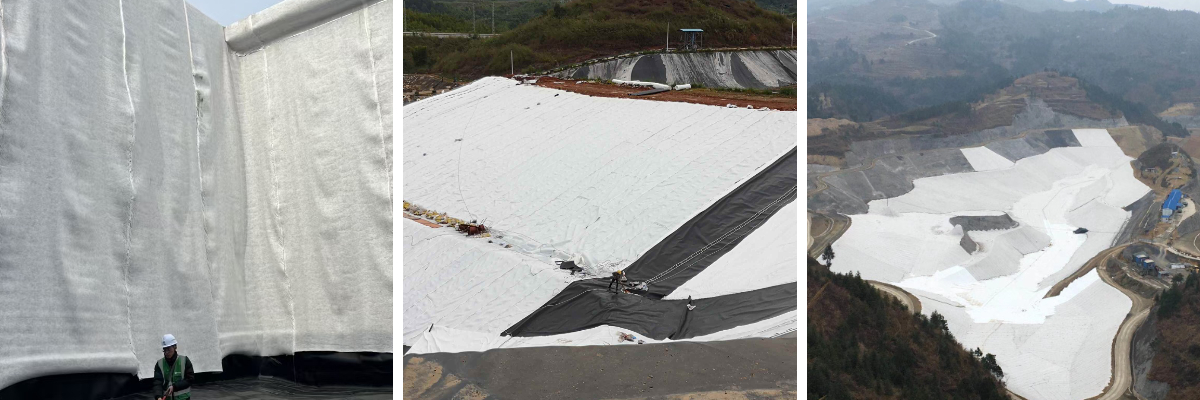

1. Highway and Railway Slope Protection: On fill/cut slopes of highways and railways, a combination of "geogrid + geotextile + sprayed greening" is used to protect against slope instability caused by rain erosion and vehicle vibration. It also restores slope vegetation, reducing maintenance costs and is suitable for road sections with complex terrain, such as mountainous and hilly areas.

2. Mine and Quarry Reforestation: For exposed rock slopes after mining, a "geogrid + eco-bag (filled with soil)" base protection layer is constructed. This stabilizes the topsoil and allows for the planting of pioneer plants, gradually restoring the slope ecology, preventing rock slides and soil erosion, and assisting in the acceptance of mine ecological restoration.

3. River and Reservoir Slope Protection: Used on the waterfront slopes of rivers and reservoirs, a combination of "anti-scour geotextile + geogrid" is employed to resist erosion during floods and protect the banks from collapse. Combined with aquatic plant planting, this approach balances flood control with ecological landscape, aligning with urban river management and protecting the surrounding ecosystems of reservoirs.

4. Municipal and Industrial Park Slope Protection: Used on municipal road slopes, park landscape slopes, and industrial park fill areas, this system utilizes "lightweight geonet + turf" to prevent soil loss caused by daily rainwater erosion while also providing beautification through vegetation cover, meeting the dual requirements of "safety + landscape" for municipal projects.

Geosynthetic Slope Protection, with its core advantages of multi-dimensional reinforcement, erosion control, ecological synergy, and flexibility and efficiency, transcends the limitations of traditional slope protection, which prioritizes engineering over ecology and has high costs and limited adaptability. Whether it's for highway and railway safety protection or ecological restoration of mining and river channels, Geosynthetic Slope Protection leverages material combinations and functional synergy to ensure slope stability while simultaneously restoring the ecological landscape. Combining safety, affordability, and sustainability, Geosynthetic Slope Protection is easy to install and adaptable to a variety of scenarios. It is an ideal solution for balancing protection effectiveness and ecological value in modern slope engineering, advancing slope protection from "hard barriers" to "flexible synergy."