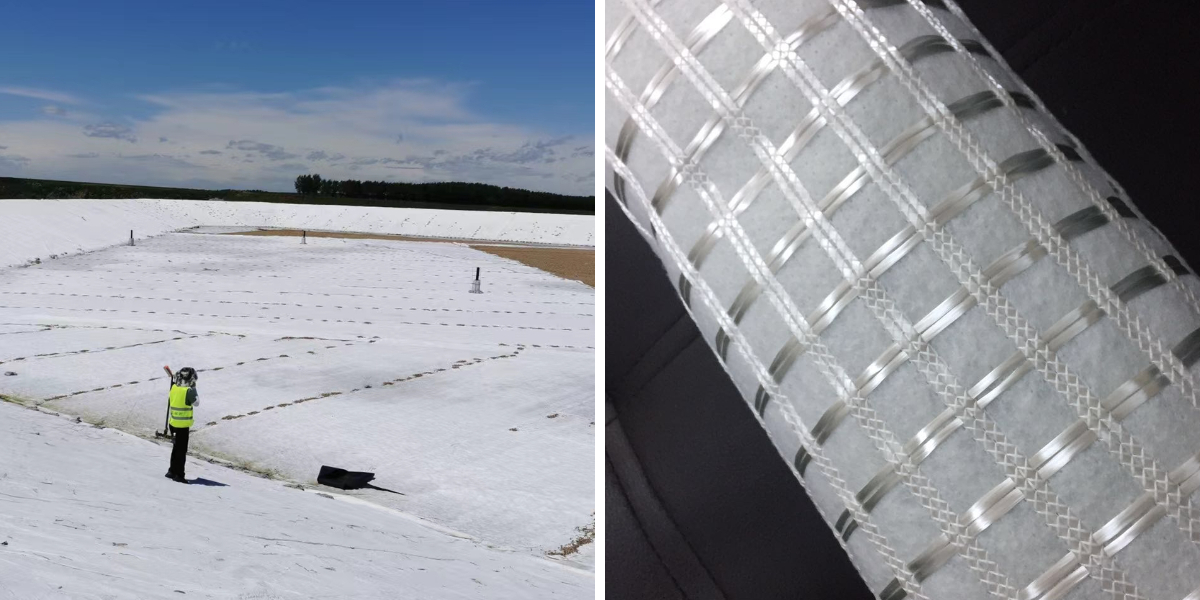

Woven Monofilament Geotextile Fabric

High tensile strength: With excellent tensile and tear strength, it can effectively disperse soil stress and adapt to long-term load-bearing scenarios such as roadbeds and dams.

Precise filtration and drainage: Uniform woven pores can accurately intercept soil particles, while ensuring rapid infiltration and drainage of water, avoiding structural damage caused by soil sedimentation or water accumulation.

Excellent weather resistance and corrosion resistance: Made of polymer monofilament raw materials, it has the ability to resist ultraviolet rays, acid and alkali corrosion, and biodegradation.

Stable dimensional form: The weaving process results in low shrinkage and strong dimensional stability of the product, which can maintain integrity and protective effect for a long time.

Convenient construction adaptation: The material is lightweight, easy to cut and splice during laying, and can adapt to complex construction terrains, reducing construction difficulty and time costs.

Product Introduction:

Woven Monofilament Geotextile Fabric is a high-performance geosynthetic material developed specifically to address the needs of soil stability, protection, and environmental remediation in engineering construction. This product is made of polymer monofilament as raw material through precision weaving technology. With its unique structural design, it combines four core advantages: high strength and tensile resistance, precise filtration and drainage, excellent weather resistance and corrosion resistance, and stable size and shape. It can maintain stable performance for a long time under complex working conditions, providing reliable guarantee for various projects.

In terms of application scenarios, this product covers multiple fields of engineering construction: highway and railway engineering, water conservancy and waterway engineering, municipal and environmental engineering, mining and energy engineering. Whether it is heavy load bearing, water protection, or harsh environmental tolerance scenarios, Woven Monoreinforcement Geotextile Fabric can reduce engineering risks, shorten construction periods, and improve overall project quality through scientific functional adaptation. It is an indispensable key material in modern engineering construction.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1、 In the field of highway and railway engineering

Layered reinforcement of roadbed: laid between the layered rolling layers of roadbed filling materials (such as sand, gravel, and soil), utilizing their high-strength tensile properties to disperse the vertical stress and horizontal thrust generated by vehicle travel, avoiding settlement and cracking of roadbed genes under long-term loads, especially suitable for the construction of high-grade highways and heavy-duty railways;

Slope protection: Lay along the slopes on both sides of the highway/railway, and fix them with anchor rods or grids to effectively prevent the slope soil from sliding down. At the same time, achieve rainwater infiltration and drainage through precise pores to prevent slope collapse caused by rainwater erosion;

Road base isolation: placed between the road base layer (such as cement stabilized crushed stone) and the roadbed soil to form a physical isolation layer, preventing fine particles in the roadbed soil from infiltrating into the base layer with moisture, preventing the base layer from hardening and reducing strength, and extending the service life of the road surface.

2、 In the field of water conservancy and waterway engineering

Dam anti-seepage reinforcement: As an auxiliary layer of the dam anti-seepage system, it is laid between the anti-seepage membrane (such as HDPE membrane) and the dam soil. On the one hand, it protects the anti-seepage membrane from being pierced by sharp particles in the dam body. On the other hand, it discharges the accumulated water inside the dam body through pores, reduces the seepage line of the dam body, and improves the anti sliding stability of the dam body;

River and Channel Slope Protection: Used in conjunction with ecological grids, precast concrete blocks, and other slope protection materials, it is laid between the slope protection structure and the river soil, intercepting soil particles to prevent river siltation, while guiding the normal infiltration of river water to avoid collapse of the slope protection structure caused by soil hollowing out below the slope protection;

Port and dock yard: In the foundation treatment of port yard, it is laid between the gravel cushion layer and the soft soil foundation to play a filtering role in preventing soft soil particles from entering the cushion layer, while enhancing the overall bearing capacity of the foundation and adapting to heavy-duty scenarios such as container stacking.

3、 In the field of municipal and environmental engineering

Municipal road and pipe network construction: In urban road renovation and expansion, as well as underground pipe network (such as rainwater pipes and sewage pipes) laying projects, it is laid between the backfill soil and the original soil around the pipeline to prevent settlement of the backfill soil and deformation of the pipeline. At the same time, the drainage function accelerates the consolidation of the backfill soil and shortens the construction period;

Landfill anti-seepage system: As the protective layer and drainage layer of the landfill lining system, it is laid above the anti-seepage membrane to isolate the leachate from the anti-seepage membrane, prevent sharp garbage from puncturing the membrane body, and guide the leachate into the collection pipe network to prevent soil and groundwater pollution;

Artificial lakes and landscape water systems: In water feature projects such as artificial lakes and landscape rivers, they are laid between the anti-seepage layer and backfill soil at the bottom of the lake to protect the anti-seepage layer and assist in drainage, preventing soil softening caused by accumulated water at the bottom of the lake and ensuring long-term stability of the water feature structure.

4、 Mining and Energy Engineering

Mine tailings pond anti-seepage: laid between the tailings pond dam body and tailings slag, forming a filtering isolation layer to prevent fine particles in the tailings slag from infiltrating and polluting the surrounding soil and groundwater with rainwater, while enhancing the anti-seepage performance of the dam body and reducing the risk of tailings pond collapse;

Foundation treatment of photovoltaic power station: during the construction of support foundation of photovoltaic power station (especially photovoltaic power station in mountainous area and mudflat), it is laid between the foundation filler and undisturbed soil, and uses high-strength characteristics to disperse support load, prevent the foundation settlement from causing the photovoltaic panel to tilt, and at the same time meet the weather resistance requirements of long-term outdoor exposure and temperature difference changes;

Oil and gas pipeline protection: In the construction of long-distance oil and gas pipeline roadbeds, it is laid under and around the pipeline to protect it from sharp stones in the soil. At the same time, the drainage function is used to keep the soil around the pipeline dry and prevent pipeline corrosion.

Woven Monofilament Geotextile Fabric is widely used in four major fields: highway and railway, water conservancy and transportation, municipal environmental protection, mining and energy. It can achieve functions such as roadbed reinforcement, slope protection, dam seepage prevention, pipeline protection, and tailings pond isolation. With its high strength, weather resistance, corrosion resistance, filtration and drainage characteristics, it ensures the stability of various engineering structures, reduces risks, and extends service life.