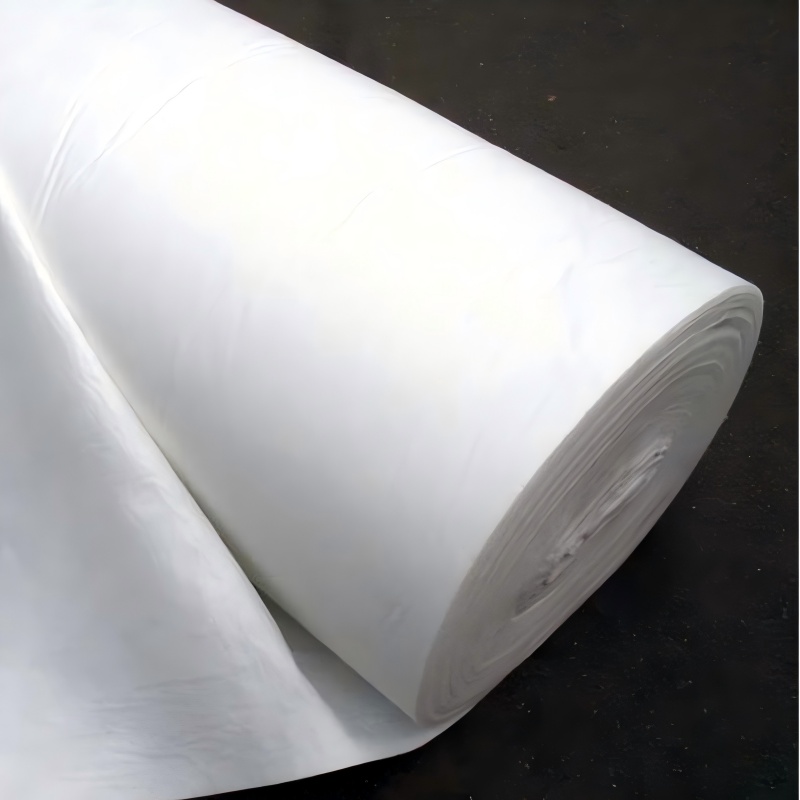

Non Woven Geo Fabric

1.Excellent filtering performance:It can intercept soil particles, sand and gravel, allow water to pass through, prevent soil loss from causing structural damage, and is suitable for scenarios such as water conservancy dams.

2.Outstanding drainage capacity:There are many pores, which can quickly drain accumulated water, reduce soil pressure, and minimize settlement problems in highway subgrade and other engineering projects.

3.Significant reinforcement effect:High tensile strength, enhances soil stability, restrains deformation, and protects railway subgrades from cracking and collapse.

4.Reliable protective effect:Isolate different materials, buffer impacts, reduce water flow erosion on riverbanks, and protect engineering and ecology.

5.Good economic viability:Lightweight, easy to transport and lay, fast construction, long lifespan, low maintenance costs, and better overall cost-effectiveness than traditional materials.

Product Introduction

Basic attributes

Non Woven Geo Fabric are made from synthetic fibers such as polyester and polypropylene through processes such as needle punching, weaving, or spunbonding. It is lightweight and flexible, with good water permeability, allowing water and gas to pass through. At the same time, its chemical properties are stable, acid and alkali resistant, and corrosion-resistant, making it suitable for different engineering environments.

Core functions

The core functions are reflected in filtration, drainage, reinforcement, and protection. When filtering, it can intercept soil particles, allow water infiltration, and prevent soil loss; Drainage can quickly drain accumulated water through internal pores, reducing soil pressure; Reinforcement can enhance the tensile performance of soil and reduce deformation; Protection can isolate different soil layers, avoid mixing, and buffer external impacts.

Main features

It has diverse functions and can meet the different needs of various projects such as water conservancy, highways, railways, etc., with a wide range of applications. Convenient construction, light weight, easy transportation and laying, simple splicing, and can shorten the construction period. Good economy, long service life, low maintenance costs in the later stage, high comprehensive cost-effectiveness, and can save costs for the project.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

Water conservancy engineering

In dam construction, geotextile is laid between the dam body and the foundation to play a filtering role, intercept soil particles, and prevent leakage of the dam body due to water flow erosion; At the same time, its drainage function can timely discharge the accumulated water inside the dam body, reduce water pressure, and ensure the stability of the dam structure. In channel engineering, it can isolate different soil layers, avoid channel collapse, and reduce the erosion of water flow on the bottom of the channel.

Highway and Railway Engineering

During the construction of highway subgrade, geotextile is laid between the subgrade soil and the sand and gravel cushion layer to isolate the two and prevent soil particles from infiltrating the cushion layer and causing deformation of the subgrade; Its reinforcement effect can enhance the bearing capacity of the roadbed and reduce road surface settlement. Laying geotextile underneath railway tracks can cushion the impact of train travel, protect track foundations, and extend the service life of railways.

Municipal Engineering

In sewage treatment plants, geotextiles can be used as filter layers in sedimentation tanks and sludge treatment areas to intercept solid particles in sludge and purify water quality; In a landfill site, it can isolate the landfill material from the surrounding soil, prevent harmful substances from infiltrating and polluting groundwater, and assist in the discharge of leachate generated by the landfill site.

Agricultural and Environmental Engineering

In agricultural irrigation channels, geotextiles can prevent channel leakage, improve water resource utilization, and protect channel slopes from water erosion. In ecological restoration projects, such as river regulation, laying geotextiles can stabilize riverbeds, provide a good environment for the growth of aquatic plants, and help restore ecosystems.

Geotextiles play a crucial role in various fields such as water conservancy, highways and railways, municipal engineering, agriculture and environmental protection, thanks to their functions of filtration, drainage, reinforcement, and protection. It can not only improve the stability and durability of engineering structures, but also contribute to environmental protection and resource conservation, making it an indispensable and important material in various types of engineering construction.