Municipal Sewer & Stormwater Projects: Geotextile Cloth for Filtration & Drainage

Municipal sewer and stormwater buildings are the backbone of metropolis infrastructure, responsible for managing wastewater, stopping flooding, and defending public health. In these projects, geotextile fabric performs an integral function in filtration, drainage, and soil stabilization—solving usual challenges like clogging, erosion, and gadget inefficiency. This facts explores how geotextile filter material and geotextile drainage material optimize municipal projects, their key benefits, applications, and choice requirements to assist engineers and contractors grant durable, high-performance systems.

1. Geotextile Cloth Types: Tailoring to Sewer & Stormwater Needs

Not all geotextile material is created equal. The typical overall performance of geotextile filter fabric and geotextile drainage fabric relies upon on their cloth composition, weave structure, and design, which need to align with the unique wants of municipal sewer and stormwater projects.

1.1 Woven Geotextile Cloth: Strength for Structural Stability

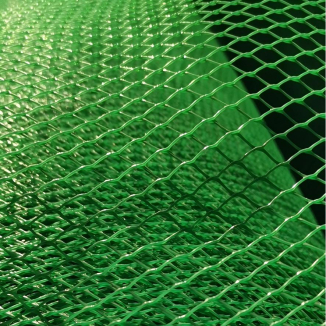

Woven geotextile cloth is crafted from polypropylene or polyester fibers interlaced in a tight grid pattern, imparting superb tensile strength, tear resistance, and dimensional stability. This type excels in features requiring load-bearing capacity and soil separation, making it a staple in municipal projects. For sewer lines, woven geotextile cloth is used to separate backfill material from the pipe bedding, stopping soil particles from infiltrating and detrimental pipe joints.

As a geotextile filter fabric, woven variants furnish managed filtration—allowing water to miss by means of even as keeping soil solids, which is integral for stormwater drainage systems. Their rigid structure resists clogging below immoderate glide rates, making certain long-term filtration efficiency. Additionally, woven geotextile cloth is ideal for reinforcing stormwater detention basins and sewer trenches, decreasing soil contract and extending the lifespan of underground infrastructure.

1.2 Non-Woven Geotextile Cloth: Superior Filtration & Drainage

Non-woven geotextile cloth is made from bonded synthetic fibers, creating a porous, felt-like cloth that prioritizes filtration and drainage over structural strength. This variety is the go-to geotextile drainage material for municipal projects, as its immoderate permeability lets in rapid water waft even as trapping exquisite soil particles. In stormwater systems, non-woven geotextile cloth prevents sediment from clogging drainage pipes, culverts, and permeable pavements.

As a geotextile filter fabric, non-woven variations grant uniform pore dimension distribution, making certain regular filtration during the entire surface. They are widely used in sewer lateral installations, the area they wrap spherical pipe perforations to filter wastewater and end root intrusion. Non-woven geotextile cloth is moreover flexible, conforming to irregular pipe shapes and trench contours, making it reachable to set up in complex metropolis environments.

1.3 Composite Geotextile Cloth: Combined Performance Advantages

Composite geotextile material integrates woven and non-woven layers, merging structural energy with higher filtration and drainage. This hybrid reply is ideal for high-demand municipal projects, such as stormwater inexperienced infrastructure (rain gardens, bioswales) and large-diameter sewer lines. The woven layer gives soil separation and reinforcement, at the same time as the non-woven layer acts as a geotextile filter fabric and geotextile drainage fabric, optimizing water waft and sediment control.

Composite geotextile fabric is moreover resistant to chemical degradation from wastewater and harsh environmental conditions, making positive sturdiness in sewer buildings dealing with industrial and residential effluent. Its versatility makes it a fairly priced wish for duties requiring extra than one geotextile functions, reducing the desire for separate supplies and simplifying installation.

2. Key Applications in Municipal Sewer & Stormwater Projects

Geotextile cloth, alongside with geotextile filter fabric and geotextile drainage fabric, is built-in into nearly every and each area of municipal sewer and stormwater projects—addressing filtration, drainage, erosion control, and structural stability needs.

2.1 Sewer Line Installations: Protection & Filtration

Sewer traces are susceptible to soil infiltration, root intrusion, and sediment buildup, which can cause blockages and pipe failure. Geotextile fabric mitigates these risks thru performing as a barrier between the pipe and surrounding soil. When wrapping perforated sewer pipes, non-woven geotextile filter fabric prevents fantastic soil particles from coming into the pipe, while allowing wastewater to go with the float freely—reducing clogging and preservation costs.

In trench backfilling, woven geotextile fabric separates the pipe bedding (sand or gravel) from native soil, stopping soil sickness of the bedding material and making certain uniform load distribution. This protects pipe joints from stress and settlement, extending the provider existence of sewer infrastructure. For corrugated plastic pipes, geotextile cloth moreover reduces friction between the pipe and backfill, simplifying set up and minimizing damage.

2.2 Stormwater Drainage Systems: Sediment Control & Flow Optimization

Stormwater buildings rely on surroundings pleasant drainage to prevent town flooding, and geotextile drainage cloth is quintessential to this function. In storm drains, culverts, and lure basins, non-woven geotextile cloth filters stormwater runoff, trapping sediment, debris, and air pollution in the past than they enter the system. This prevents clogging of pipes and reduces the threat of flooding at some factor of heavy rainfall.

Geotextile cloth is moreover integral in permeable pavement systems, which manipulate stormwater by using enabling it to infiltrate into the ground. Non-woven geotextile filter material located beneath the pavement layer filters runoff, stopping soil particles from clogging the permeable mixture and keeping drainage efficiency. In stormwater detention ponds, woven geotextile cloth reinforces the pond lining, stopping erosion and stabilizing the soil at the same time as allowing water to drain slowly into the groundwater table.

2.3 Green Infrastructure: Erosion Control & Sustainability

Modern municipal initiatives greater and extra undertake inexperienced infrastructure (GI) to manipulate stormwater sustainably, and geotextile fabric is a key thing of these systems. In rain gardens, bioswales, and inexperienced roofs, geotextile filter fabric prevents soil erosion even as facilitating water infiltration. Non-woven variations allow stormwater to seep into the soil, recharging groundwater, even as defending soil solids and stopping the outside mattress from washing away.

Geotextile drainage material moreover optimizes water go with the drift in GI systems, making positive greater stormwater is drained efficaciously to preserve away from waterlogging. For example, in inexperienced roofs, a layer of non-woven geotextile fabric beneath the drainage layer filters water and prevents root penetration into the drainage system. This enhances the universal performance of inexperienced infrastructure, lowering metropolis warmness island effects and improving water quality.

3. Critical Selection & Installation Tips for Optimal Performance

To maximize the effectiveness of geotextile fabric in municipal projects, ideal desire and set up are essential. Factors like assignment requirements, soil type, and environmental stipulations want to be considered to select the suitable geotextile filter fabric or geotextile drainage fabric.

3.1 Selection Criteria: Matching Material to Project Needs

The first step in identifying on geotextile fabric is defining the project’s indispensable goal—filtration, drainage, reinforcement, or erosion control. For filtration-focused features (e.g., sewer pipe wrapping), pick out non-woven geotextile filter cloth with a pore dimension nicely matched with the soil form (typically 0.05-0.2 mm for extremely good soils). For drainage functions (e.g., stormwater culverts), prioritize non-woven geotextile drainage material with immoderate permeability (≥100 m/s) to make positive fast water flow.

Soil sort moreover influences selection: cohesive soils (clay, silt) require geotextile cloth with finer pores to stop clogging, while granular soils (sand, gravel) can use coarser woven variants. Additionally, suppose about chemical resistance—sewer duties dealing with industrial wastewater choose geotextile cloth resistant to acids, alkalis, and herbal solvents to maintain away from degradation.

3.2 Installation Best Practices: Avoiding Common Pitfalls

Improper set up can negate the benefits of geotextile cloth, major to premature failure. Start thru getting equipped the set up site: forged off sharp rocks, debris, and vegetation that ought to puncture the geotextile. For trench applications, make positive the trench bottom is easy and compacted before than laying the geotextile cloth.

When placing in geotextile filter fabric or geotextile drainage fabric, overlap seams via 15-30 cm (6-12 inches) to end water from bypassing the filter. Use like minded fasteners (staples, pins) to tightly closed the geotextile to the soil, heading off nervousness that must tear the material. For sewer pipes, wrap the geotextile tightly spherical the pipe, making positive full insurance plan of perforations except overlapping excessively, which need to keep away from flow.

Post-installation inspection is critical: check for tears, punctures, or wrong seams, and fix any damage immediately. Avoid exposing geotextile cloth to direct sunlight hours for extended intervals previously than installation, as UV radiation can degrade synthetic fibers—store resources in shaded areas and set up promptly.

Final Takeaway: Geotextile Cloth as a Municipal Infrastructure Workhorse

Geotextile cloth, which encompass geotextile filter fabric and geotextile drainage fabric, is an necessary fabric in municipal sewer and stormwater projects. Its viable to optimize filtration, drainage, and soil stabilization enhances machine durability, reduces maintenance costs, and helps sustainable infrastructure goals. By figuring out on the acceptable geotextile variety and following appropriate set up practices, engineers and contractors can make positive municipal buildings function reliably for decades.

Whether for sewer line protection, stormwater management, or inexperienced infrastructure, geotextile material provides cost-effective, long-term preferences that address the distinctive challenges of metropolis infrastructure. Invest in excellent geotextile elements and professional set up to maximize mission success and shield public health and safety.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province