How HDPE Geomembrane Ensures Effective Waterproofing in Construction Projects

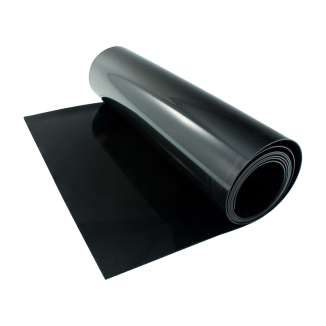

Waterproofing is a cornerstone of lengthy lasting construction, as even minor moisture intrusion can lead to structural decay, mold growth, and costly repairs. High-Density Polyethylene (HDPE) geomembrane has emerged as a game-changer in this field, offering a exceptional blend of strength, flexibility, and impermeability. Whether referred to as hdpe membrane, high density polyethylene geomembrane, or geomembrana in hdpe, this material has emerge as essential for projects where dependable waterproofing is non-negotiable. Let’s discover its key attributes and how it delivers consistent consequences throughout diverse applications.

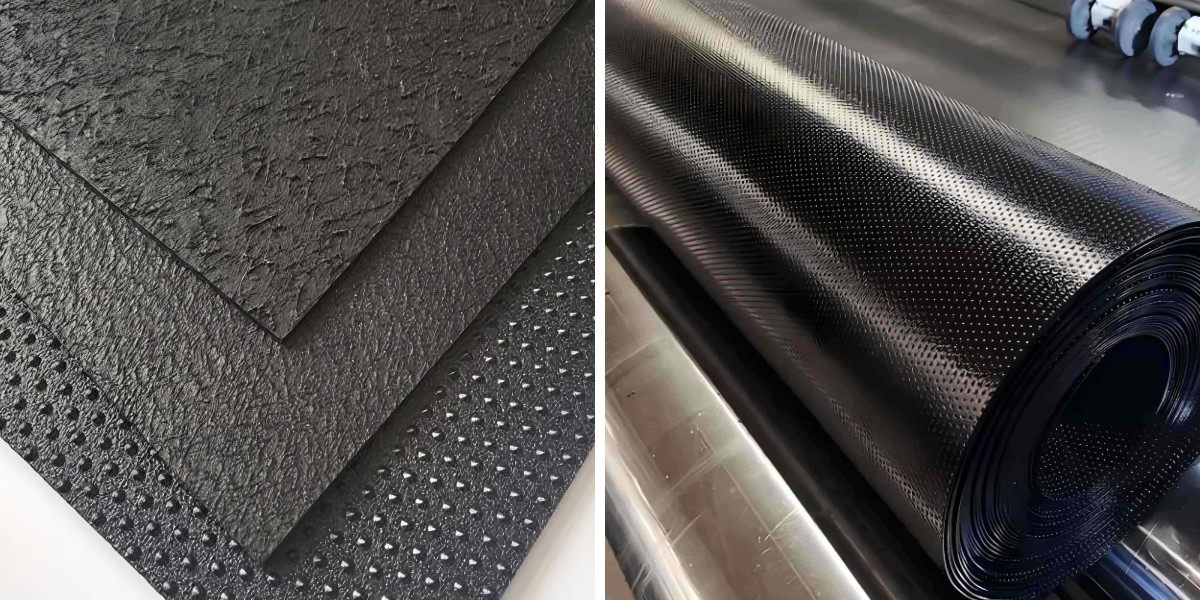

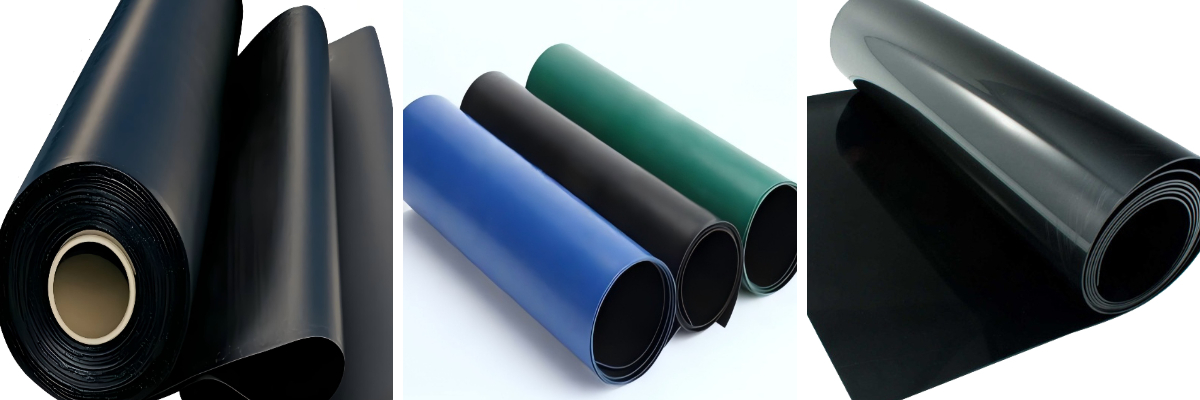

1. The Science Underpinning HDPE Geomembrane's Impermeability

At the heart of HDPE geomembrane’s effectiveness is its molecular structure. High-density polyethylene is polymerized below excessive pressure, creating a linear chain of molecules with minimal branching. This tight packing leaves no gaps for water molecules to penetrate, resulting in an noticeably low permeability rate—between 10⁻¹¹ and 10⁻¹³ cm/s. To put this in perspective, a 1mm-thick sheet of excessive density polyethylene geomembrane can withstand the pressure of 30 meters of water except permitting significant leakage, a feat unmatched by ordinary substances like clay or asphalt.

Manufacturers enhance this base structure with imperative additives. Carbon black (2–3% via weight) acts as a UV stabilizer, absorbing harmful radiation and preventing photo-oxidation, which is why geomembrana in hdpe stays functional even after many years of direct sunlight publicity in desert or coastal areas. Antioxidants are also integrated to face up to degradation from oxygen, ensuring the material retains flexibility in extreme temperatures—from -60°F in Arctic areas to 140°F in desolate tract climates.

Another key advantage is chemical resistance. Hdpe membrane can withstand publicity to industrial solvents, acids (pH 2–12), and hydrocarbons, making it ideal for chemical storage amenities or industrial waste sites. Unlike rubber liners, which can swell or degrade when in contact with such substances, high density polyethylene geomembrane keeps its structural integrity, ensuring long-term waterproofing even in harsh chemical environments.

2. Applications Spanning Multiple Construction Sectors

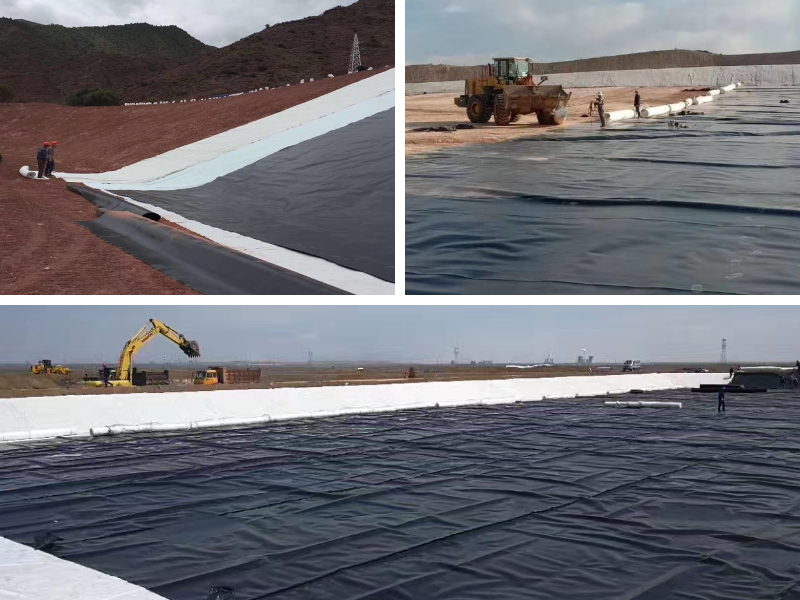

2.1 Municipal Waste Management

Landfills pose a substantial environmental risk due to leachate—toxic liquid fashioned by decomposing waste. Without suited containment, leachate can contaminate groundwater and soil, endangering ecosystems and public health. This is where hdpe membrane shines: contemporary landfills use a multi-layer system with at least two layers of excessive density polyethylene geomembrane. The primary layer sits immediately on the compacted subgrade, while a secondary layer (with a drainage community in between) acts as a failsafe. This design reduces leakage hazard to less than 0.001% annually.

A notable instance is the Fresh Kills Landfill in New York, as soon as the largest in the world. After closure, it was included with a 2mm-thick geomembrana in hdpe, paired with a drainage layer and soil cap. Post-installation monitoring confirmed a 99% reduction in leachate migration, proving the material’s effectiveness in long-term waste containment.

2.2 Water Resource Management

Efficient water storage and distribution are critical, especially in water-scarce regions. HDPE geomembranes play a necessary position in reservoirs, canals, and irrigation systems. High density polyethylene geomembrane liners in reservoirs reduce seepage by up to 95% in contrast to unlined structures, conserving thousands and thousands of gallons annually. For instance, a 50-acre reservoir lined with hdpe membrane in California saves enough water to furnish 10,000 households yearly.

Canals and irrigation ditches also benefit: the clean surface of geomembrana in hdpe reduces friction, permitting water to flow greater efficiently and reducing pumping costs via 15–20%. In arid regions like Australia’s Murray-Darling Basin, lined irrigation channels have accelerated water delivery effectivity from 60% to over 90%, supporting sustainable agriculture.

2.3 Building and Infrastructure Construction

Underground structures like basements, tunnels, and parking garages are in particular prone to groundwater intrusion. Hdpe membrane provides a robust solution: in basement construction, it is established as a pre-concrete barrier, conforming to uneven surfaces to block moisture. Its flexibility permits it to withstand minor ground shifts except cracking, a key benefit over rigid materials like concrete.

Tunnels, such as the Channel Tunnel linking the UK and France, use excessive density polyethylene geomembrane between concrete segments. This prevents water from seeping into the tunnel, decreasing corrosion of steel reinforcements and lowering renovation costs. Over 30 years of operation, the liner has averted an estimated 10,000+ gallons of water intrusion daily.

2.4 Industrial Applications

Industrial facilities handling hazardous materials take into account on geomembrana in hdpe for containment. Chemical plants use hdpe membrane to line storage tanks and secondary containment areas, ensuring spills of acids or solvents do not reap soil or water sources. In oil refineries, high density polyethylene geomembrane lines tank farms, withstanding exposure to crude oil and petroleum merchandise barring degradation.

A case study from a Texas chemical plant showed that switching to HDPE geomembrane decreased containment disasters by 80% compared to preceding rubber liners, ensuing in $2 million in annual savings from avoided cleanup charges and regulatory fines.

3. Installation Techniques for Optimal Waterproofing Performance

3.1 Surface Preparation

Proper floor preparation is critical to maximize the effectiveness of excessive density polyethylene geomembrane. For landfills, the subgrade is compacted to 95% Proctor density the usage of vibrating rollers, ensuring a stable base. Sharp rocks, roots, and particles are removed to forestall punctures—any remaining protrusions over 25mm are blanketed with a 5cm layer of sand or geotextile.

In building projects, concrete surfaces are cleaned and primed to enhance adhesion. For uneven substrates, a self-leveling compound may also be utilized to create a smooth base, ensuring the hdpe membrane lies flat and forms a continuous seal.

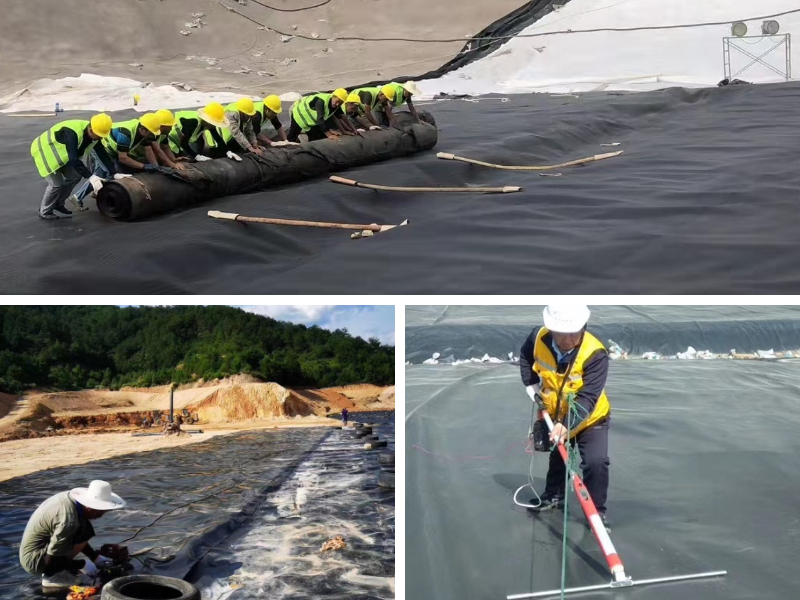

3.2 Welding and Seaming

Welding is the key to creating a seamless waterproof barrier. Extrusion welding is preferred for thick membranes (1.5mm+), the utilization of a heated nozzle to melt the membrane edges and a HDPE filler rod, forming a bond stronger than the membrane itself. Welding speed is managed at 1–3 meters per minute to make sure proper fusion.

For thinner membranes, hot air welding makes use of heated air (200–220°C) to melt overlapping edges, which are then pressed collectively with a roller. Post-welding, every seam is tested: vacuum trying out (drawing 25kPa of pressure) detects leaks, with any defects repaired immediately. A 10,000m² installation normally requires 500+ weld tests to make certain integrity.

3.3 Anchoring and Edge Treatment

Anchoring prevents geomembrana in hdpe from shifting due to water stress or wind. In landfills, edges are buried in 30cm-deep trenches filled with compacted soil, or secured with concrete “deadmen” (30cm x 30cm blocks) spaced each and every two meters. For vertical applications like retaining walls, mechanical fasteners (stainless metal screws with washers) are used, with sealant utilized around each fastener to forestall leaks.

Corners and penetrations (e.g., pipes) are bolstered with 30cm-wide patches, creating a double-sealed junction. This “patch and weld” method ensures no susceptible factors in critical areas.

3.4 Quality Control and Inspection

Rigorous inspections are conducted all through installation. During laying, visible checks identify tears or folds; after welding, digital leak detection (using a high-voltage probe) finds pinholes as small as 0.01mm. A third-party inspector verifies 100% of seams, with documentation saved digitally for compliance audits.

Post-installation, a final inspection consists of a “flood test” for reservoirs (filling with water and monitoring for 72 hours) or pressure checking out for industrial tanks. Any problems are addressed before project handover, making sure the hdpe membrane device meets performance standards.

4. Long-Term Durability and Cost-Effectiveness

4.1 Lifespan and Performance

With proper installation, excessive density polyethylene geomembrane has a provider life of 50+ years. Accelerated aging exams exhibit it retains 80% of its tensile strength after 20 years of UV exposure, far exceeding the 10–15 12 months lifespan of asphalt or rubber liners. Its resistance to organic growth (mold, roots) also eliminates degradation from natural activity, a frequent issue with natural materials.

In bloodless climates, hdpe membrane’s flexibility prevents cracking at some stage in freeze-thaw cycles, while in tropical regions, its chemical stability resists degradation from humidity and fungi. This versatility ensures consistent standard performance across global environments.

4.2 Maintenance Requirements

HDPE geomembrane requires minimal maintenance. Annual inspections test for punctures (e.g., from equipment) or seam damage, with repairs accomplished quickly using extrusion-welded patches. Unlike concrete liners, which want regular patching, geomembrana in hdpe typically requires less than 1 hour of upkeep per 1,000m² annually.

A learn about of 100 landfill liners found that HDPE required 70% fewer repairs than clay liners over 20 years, lowering long-term operational expenses significantly.

4.3 Cost-Effectiveness

While initial costs for hdpe membrane are greater than clay (2–3x), long-term financial savings are substantial. A 100,000m² landfill liner costs \(300,000–\)400,000 upfront however avoids $2–3 million in replacement fees (compared to asphalt liners needing alternative every 15 years).

Water initiatives see similar savings: a lined irrigation canal in India reduced water loss by way of 80%, reducing pumping costs by $50,000 annually. Over 50 years, these financial savings outweigh the preliminary investment in high density polyethylene geomembrane by 5–10x.

Conclusion

HDPE geomembrane—whether referred to as hdpe membrane, excessive density polyethylene geomembrane, or geomembrana in hdpe—sets the standard for waterproofing in construction. Its scientific design, versatile applications, precise set up techniques, and long-term durability make it a affordable solution for defending infrastructure, the environment, and public health. As construction demands grow, HDPE geomembrane will stay a fundamental tool in building resilient, sustainable buildings that stand the check of time.

Contact Us

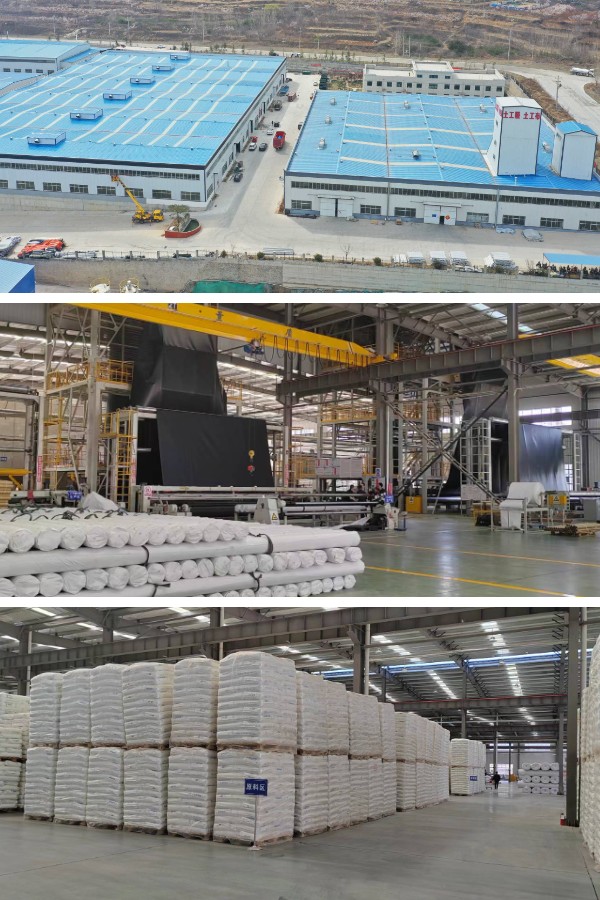

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province