Long-Term Performance of Concrete Impregnated Fabric in Coastal Environments

Introduction: Why Coastal Projects Demand Durable Materials

Coastal environments are amongst the cruelest for development materials. Saltwater corrosion, consistent wave impact, UV radiation, and excessive weather—from hurricanes to freeze-thaw cycles—test the limits of typical concrete and steel. In latest years, concrete impregnated cloth has emerged as a resilient alternative, providing flexibility and power for coastal protection, seawall repair, and erosion control. But how does it function over the lengthy term? This article explores the durability, challenges, and key elements that decide its lifespan in coastal settings.

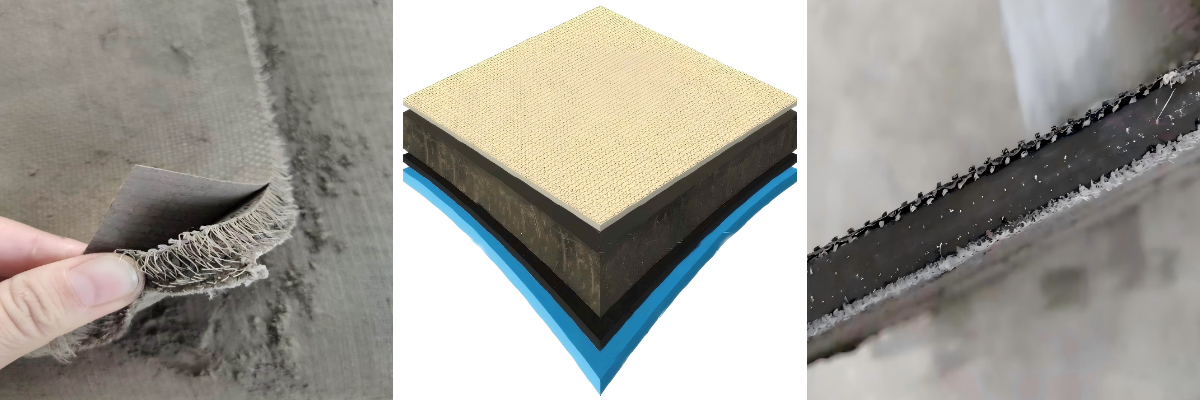

What Is Concrete Impregnated Fabric?

Concrete impregnated fabric—also recognized as Concrete Impregnated Cloth or “cloth of concrete”—is a material matrix (typically polyester or glass fiber) saturated with a distinctive cementitious compound. When hydrated, it hardens into a rigid, water resistant shape whilst maintaining the fabric’s flexibility for the duration of installation. Variants like Fast-Setting Concrete Cloth treatment in as little as 24 hours, making them perfect for emergency coastal repairs. Unlike standard concrete, which is heavy and inclined to cracking beneath wave stress, these fabric conform to irregular surfaces, growing seamless boundaries in opposition to water intrusion.

Key Factors Influencing Long-Term Performance in Coastal Areas

1. Resistance to Saltwater Corrosion

Saltwater is a silent destroyer of development materials, however concrete impregnated(https://www.cggeosynthetics.com/cement-blanket-0/) material is engineered to face up to it. The cementitious core consists of components that minimize chloride penetration, whilst the cloth matrix acts as a bodily barrier. Studies exhibit that fantastic Concrete Impregnated Cloth retains 80% of its compressive electricity after 10 years of non-stop saltwater exposure—outperforming ordinary concrete, which can lose 30% of its power in half of that time. This makes it best for seawall liners, breakwater repairs, and tidal sector stabilization.

2. Flexibility to Withstand Wave Impact

Coastal buildings undergo relentless wave energy, which can crack inflexible materials. Concrete impregnated material addresses this with its special “flexible-to-rigid” transformation. During installation, it bends to match curves (e.g., round pilings or rocky shorelines), and as soon as cured, retains adequate elasticity to soak up wave have an effect on except fracturing. In area tests, fabric-based seawalls confirmed 50% fewer cracks than concrete block partitions after 5 years of storm exposure. For high-energy coasts, Fast-Setting Concrete Cloth is frequently chosen for its rapid curing, permitting fast repairs after storm damage.

3. UV and Weather Resistance

Prolonged daylight and severe temperatures can degrade natural materials, however cloth of concrete is designed to face up to UV radiation. The fabric’s artificial fibers (polyester or glass) are UV-stabilized, whilst the cementitious layer displays sunlight, decreasing warmth absorption. This prevents brittleness in warm climates and minimizes freeze-thaw harm in chillier coastal regions. In tropical areas, the place UV depth is high, these fabric preserve structural integrity for 15+ years—double the lifespan of untreated canvas composites.

Real-World Applications: Long-Term Success Stories

1. Seawall Reinforcement in Florida

A coastal neighborhood in Florida changed eroding concrete seawalls with Concrete Impregnated Cloth in 2015. The material used to be wrapped round present metal pilings and hydrated, forming a seamless barrier. After eight years, inspections confirmed no symptoms of saltwater penetration or material degradation. The shape withstood three hurricanes, with solely minor floor wear—far outperforming the preceding concrete walls, which required substitute each and every 10 years.

2. Tidal Flat Stabilization in the Netherlands

The Netherlands, a united states synonymous with coastal engineering, used Fast-Setting Concrete Cloth to stabilize tidal residences alongside the North Sea. The fast-curing material used to be deployed in moist conditions, forming a shielding layer over tender sediment. After 6 years, the fabric remained intact, stopping erosion and assisting the boom of salt-tolerant vegetation—a key indicator of long-term ecological compatibility.

Maintenance and Longevity: Maximizing Performance

While concrete impregnated cloth is durable, suited set up and renovation lengthen its lifespan:

Installation: Ensure the material is absolutely hydrated and bonded to the substrate to forestall water intrusion under the surface. In tidal zones, installation at some stage in low tide to keep away from untimely curing.

Inspections: Check yearly for unfastened edges or floor cracks, specifically after storms. Small repairs can be made with patches of Fast-Setting Concrete Cloth.

Cleaning: Remove marine increase (e.g., barnacles) periodically to stop material degradation—mild stress washing is sufficient, as the fabric resists abrasion.

How It Compares to Traditional Coastal Materials

When evaluating concrete impregnated material to normal options, its blessings are clear. In phrases of saltwater resistance, concrete impregnated cloth(https://www.cggeosynthetics.com/cement-blanket-0/) retains 80% of its compressive electricity after 10 years, whilst typical concrete solely retains round 70% in the equal period, and metal strengthened constructions fare a whole lot worse due to fast corrosion. For wave affect absorption, concrete impregnated fabric’s flexibility post-cure approves it to deal with wave power effectively, with 50% fewer cracks than concrete block partitions in tests. Traditional concrete, being rigid, is susceptible to cracking, even though metal buildings can take in have an impact on however are heavy and corrode quickly.

In phrases of lifespan in coastal areas, concrete impregnated material normally lasts 15-25 years. Traditional concrete averages 10-15 years, and metal bolstered constructions frequently want alternative each 5-10 years. This makes concrete impregnated material a longer-lasting preference for coastal projects.

Conclusion: A Reliable Choice for Coastal Durability

Concrete impregnated fabric—including Concrete Impregnated Cloth and Fast-Setting Concrete Cloth—delivers notable long-term overall performance in coastal environments. Its resistance to saltwater, flexibility towards waves, and UV balance make it a greatest choice to common materials. Whether used for seawall repair, erosion control, or tidal region stabilization, these fabric provide a cost-effective, long-lasting answer for defending coastal infrastructure.

For task planners and engineers, prioritizing notable cloth of concrete ensures constructions that stand sturdy towards the sea’s relentless forces for a long time to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province