Woven vs. Non-Woven Geofabric: Which Type is Right for Your Project?

When planning a development or landscaping project, the substances you select for the basis are simply as crucial as these you see on the surface. Among the most crucial foundational substances is material geotextile. But with distinctive kinds available, how do you choose? The debate frequentlycomes down to two important contenders: woven geotextile cloth and Non-Woven Geofabric.

Selecting the incorrect kind can lead to venture failure, drainage issues, or needless expenses. This complete information will ruin down the key differences, properties, and best purposes for every kindof geotextile fabric, empowering you to make the ideal desire for your precise needs.

Understanding the Core Difference: Manufacturing Makes the Material

The essential distinction between woven and non-woven geotextiles lies in their manufacturingprocess, which without delay dictates their bodily residences and performance.

What is Woven Geotextile Fabric?

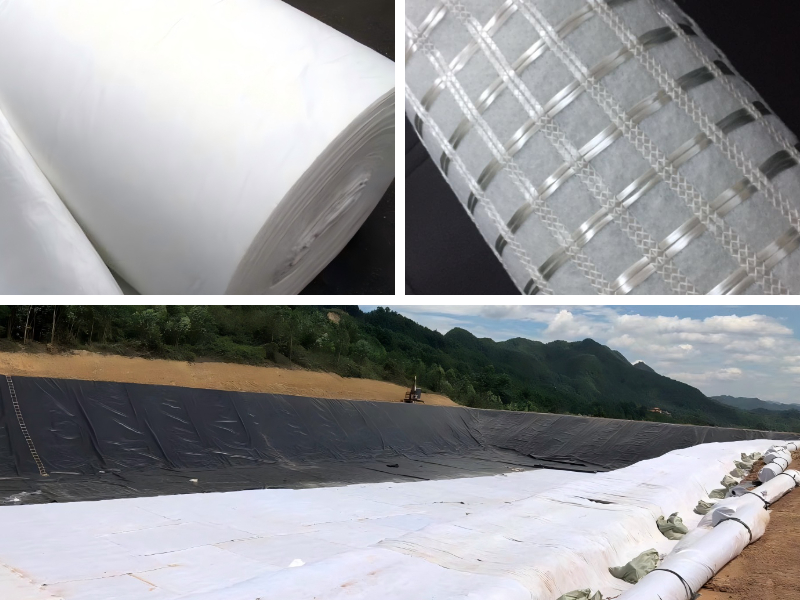

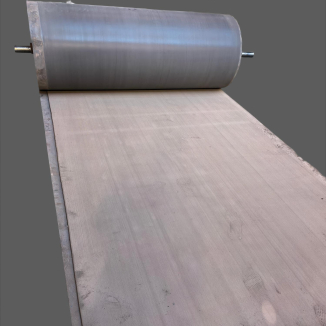

Woven geotextile cloth is manufactured with the aid of interlacing parallel units of flat or spherical artificial tapes or filaments—typically polypropylene or polyester—on a loom, plenty like typical apparel textiles. This technique creates a regular, sheet-like shape with a awesome pattern. The end result is a very strong, dimensionally stable, and porous material. Its foremost characteristic is reinforcement and separation, making it a heavyweight champion for high-stress applications.

What is Non-Woven Geofabric?

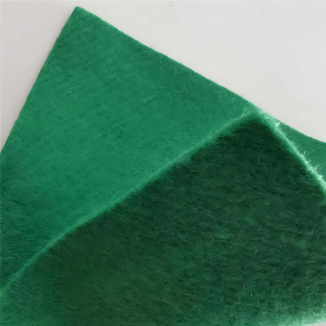

Non-Woven Geofabric is created via a absolutely distinct process. Instead of being woven, brief or non-stop artificial fibers are randomly organized into a web-like structure. This net is then bonded collectively thru one of two predominant methods: needle-punching (mechanically entangling the fibers with barbed needles) or heat-bonding. This random fiber association offers Non-Woven Geofabric its signature felt-like texture and makes it an splendid desire for filtration, drainage, and protection.

Key Performance Characteristics Compared

To make an knowledgeable decision, you want to recognize how every material geotextile performs below precise conditions.

1. Tensile Strength and Load Capacity

This is the place woven geotextile material sincerely excels. The interlocking weave sample gives brilliant tensile strength, which means it can stand up to full-size pulling forces barring stretching or tearing. This excessive tensile power makes it best for reinforcing vulnerable subgrades, such as tender soil, and for assisting heavy hundreds in functions like parking lots, get right of entry to roads, and embankments. If your task entails stabilizing soil beneath sizeable weight, a woven geotextile material is regularly the most excellent choice.

Conversely, Non-Woven Geofabric has decrease tensile power in contrast to its woven counterpart of the identical weight. Its random fiber shape is much less high-quality at resisting high-tensile forces. It is now not usually used for foremost reinforcement but can grant secondary stabilization and is terrificfor protection roles.

2. Permeability and Water Flow

Water waft is a integral aspect in many projects.

Woven geotextile cloth has a greater structured, sieve-like pore structure. It approves water to bypass thru whilst stopping soil particles from migrating. However, its go with the flow fee (permittivity) is typically decrease than that of non-woven materials. It is designed for separation and stabilization the place water go with the flow is a secondary concern.

Non-Woven Geofabric is the champion of water management. Its random, felt-like shape has a excessive float price each perpendicular and parallel to its plane. This permits it to effectively acquireand transport water, making it the go-to cloth geotextile for French drains, subsurface drainage systems, erosion control, and different purposes the place managing water is the important goal.

3. Filtration and Separation

Both kinds operate separation and filtration, however they do so in unique ways.

Woven geotextile material acts as a sharp separation barrier. Its unique pore openings are tremendousfor stopping the intermixing of two distinctive soil kinds (e.g., gravel and smooth subsoil), which is integral for retaining the integrity and load-bearing capability of mixture layers.

Non-Woven Geofabric offers gold standard filtration in dynamic situations. Its tortuous, multi-directional pore shape is higher at stopping soil particles from clogging the cloth geotextile itself, a phenomenon recognized as "blinding." This makes it best for use in the back of preserving partitionsor in drainage trenches the place regular water glide should clog a much less forgiving material.

Choosing the Right Geofabric for Your Project

Now that we recognize the properties, let's follow this know-how to real-world scenarios. Choosing the right cloth geotextile is the key to long-term task success.

When to Choose Woven Geotextile Fabric

Select a woven geotextile material when your project's main want is energy and stabilization. Its excessive tensile power makes it necessary for:

●Road and Pavement Construction: Placed between the subgrade and the base aggregate, it prevents the stone from sinking into gentle soil, considerably extending the lifestyles of driveways, parking lots, and get entry to roads.

●Parking Lots and Heavy Load Areas: It reinforces the floor to assist the steady stress from vehicles.

●Embankment and Slope Reinforcement: It offers the tensile power wanted to maintain soil in area on steeper slopes.

●Underneath Railroad Tracks: It stabilizes the ballast and sub-ballast layers.

In all these applications, the important position of the woven geotextile cloth is to create a stable, separated platform that can undergo heavy, long-term loads.

When to Choose Non-Woven Geofabric

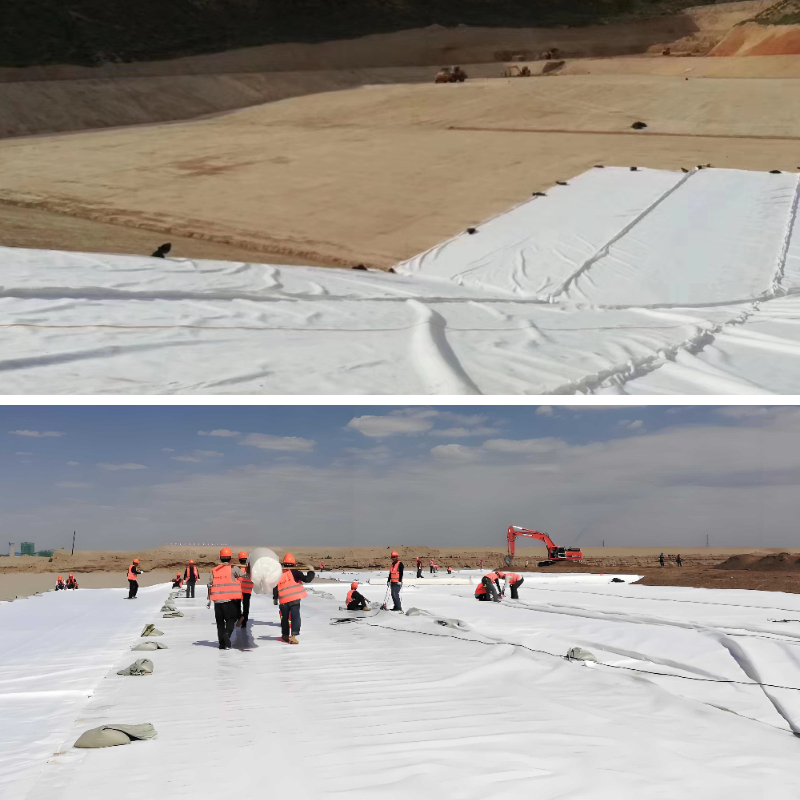

Choose a Non-Woven Geofabric when your project's focal point is on drainage, filtration, or protection. Its most suitable water dealing with skills make it ideal for:

●French Drains and Subsurface Drainage: This is the basic use for Non-Woven Geofabric. It wraps rounda perforated pipe and aggregate, permitting water to filter in whilst maintaining soil and particles out.

●Erosion Control: It is used underneath riprap (rock armor) on slopes or seashores to forestall soil erosion whilst permitting for water passage.

●Landfill and Pond Liners Protection: Placed under a geomembrane liner, the cushioning impact of Non-Woven Geofabric protects the liner from puncture by using sharp stones in the subgrade.

●Asphalt Overlay: Used as a pavement interlayer, it helps manipulate cracking and affords a moisture barrier.

If your venture includes managing water or cushioning touchy materials, Non-Woven Geofabric is nearly constantly the right answer.

Conclusion: It’s All About Function

There is no generic "best" kind of material geotextile—only the high-quality one for your particularproject. The preference between woven geotextile material and Non-Woven Geofabric is a useful one, dictated with the aid of the predominant venture you want to solve.

●For Strength and Stabilization: The structured, high-tensile nature of woven geotextile cloth is your exceptional bet.

●For Drainage and Filtration: The felt-like, high-flow homes of Non-Woven Geofabric are unmatched.

Before you purchase, cautiously examine the major motive of the geotextile cloth in your project. Are you constructing a robust foundation, or are you managing water flow? By matching the material's inherent strengths to your project's core requirements, you make certain a durable, successful, and in your price range outcome. Investing in the proper cloth geotextile from the start is an investment in the toughness of your complete project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province