Maximizing Filtration Efficiency: Tips for Proper Slurry Loading

Slurry dewatering is a imperative technique throughout industries like construction, mining, agriculture, and wastewater treatment—its purpose is to separate solids from drinks efficiently, decreasing waste quantity and enabling protected disposal or reuse of each fractions. The cornerstone of profitable dewatering lies in filtration efficiency, and nothing influences this greater than ideal slurry loading. Whether the use of Dewatering Bags, Sludge Dewatering Bags, or integrating with Erosion Control Tubes for website management, how you load slurry without delay influences processing time, solids capture, and normal cost-effectiveness. This information dives into the artwork and science of acceptable slurry loading, exploring key techniques, frequent pitfalls to avoid, and how to leverage dewatering options to their full potential.

The Link Between Slurry Loading and Filtration Efficiency

Filtration effectivity in dewatering relies on a refined balance: the slurry need to be allotted evenly to maximize contact with the filter medium (like the geotextile of Dewatering Bags), whilst keeping off overloading that clogs pores or reasons structural stress. When slurry is loaded incorrectly—too quickly, unevenly, or with inconsistent solids content—the filter can grow to be saturated, liquid drainage slows, and solids might also skip the filter, lowering the best of each the separated liquid and strong cake.

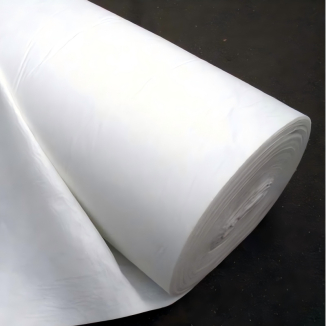

Sludge Dewatering Bags and Dewatering Bags are designed with permeable geotextile fabric that entice solids whilst permitting water to drain. Proper loading ensures the fabric’s pores stay open lengthy sufficient to entire dewatering, as an alternative than turning into blocked by means of a centred mass of solids. Additionally, when dewatering web sites are paired with Erosion Control Tubes to manipulate runoff from the bags, environment friendly loading minimizes extra liquid that ought to weigh down erosion manage measures, developing a extra cohesive and advantageous website system.

Key Preparation Steps Before Slurry Loading

Maximizing filtration effectivity starts offevolved earlier than the first drop of slurry enters the bag. Taking these preparatory steps units the stage for easy loading and most appropriate performance:

1. Assess Slurry Characteristics

Not all slurries are the same—their solids content, particle measurement distribution, and viscosity differ widely. For example, mining slurry can also have coarse, dense solids, whilst agricultural sludge is finer and extra organic. Understanding these qualities helps pick out the proper Sludge Dewatering Bags (e.g., with excellent geotextile pore size) and decide loading parameters. A slurry with excessive solids content material might also require pre-thinning to keep away from instantaneous clogging, while a low-solids slurry may want slower loading to stop uneven distribution.

2. Select the Right Dewatering Solution

Match the dewatering device to the slurry and venture needs:

Dewatering Bags: Ideal for medium to low-solids slurries (e.g., building website runoff, agricultural manure). Their bendy plan contains varying volumes and is convenient to transport.Sludge Dewatering Bags: Engineered for high-solids, dense slurries (e.g., wastewater sludge, mining tailings). They characteristic thicker, greater long lasting geotextiles to manage heavier masses and face up to tearing.

For giant sites, pair these baggage with Erosion Control Tubes positioned round the dewatering location to seize any overflow or runoff, making sure environmental compliance and website online safety.

3. Prepare the Dewatering Site

Clear the web page of rocks, debris, or sharp objects that should puncture Dewatering Bags. Level the floor and lay a geotextile underlay to forestall soil illness and enhance drainage. If the use of a couple of bags, house them evenly to permit air circulation and get entry to for monitoring. Install Erosion Control Tubes alongside the site’s perimeter or drainage paths to redirect extra liquid away from touchy areas—this step is fundamental for stopping erosion whilst the luggage dewater.

Proper Slurry Loading Techniques for Maximum Efficiency

With coaching complete, focal point on these loading strategies to optimize filtration:

1. Control Loading Rate and Pressure

The largest mistake in slurry loading is speeding the process. High-pressure pumping or speedy filling can crush Sludge Dewatering Bags, inflicting the geotextile to stretch, pores to clog, or even the bag to burst. Instead, use a low-pressure pump (typically 5–10 psi) and preserve a steady, sluggish loading rate. This approves the liquid to drain steadily as solids accumulate, stopping saturation and making sure even solids distribution throughout the bag’s surface.

2. Distribute Slurry Evenly

Uneven loading creates “hot spots”—areas the place solids pile up, blockading drainage, whilst different components of the bag stay underutilized. To keep away from this, use a diffuser or a couple of inlet factors when filling Dewatering Bags. If the usage of a single inlet, cross the hose periodically (while preserving low pressure) to unfold the slurry throughout the bag’s interior. Aim for a uniform solids layer—this maximizes the filter location in use and speeds up ordinary dewatering time.

3. Monitor Solids Concentration and Adjust as Needed

Slurry traits can alternate mid-process (e.g., if a new batch of cloth is added). Regularly take a look at the solids content—if it will become too high, skinny the slurry with water (in moderation) to preserve flowability. If solids are too low, enable the modern-day load to dewater barely earlier than including more, to keep away from diluting the filter cake. Consistent monitoring ensures the Sludge Dewatering Bags aren’t compelled to cope with slurry backyard their sketch parameters.

4. Avoid Overfilling the Bags

It’s tempting to fill Dewatering Bags to their most capacity, however overfilling stretches the geotextile, reduces its filtration efficiency, and will increase the chance of tearing. Most dewatering luggage are designed to be crammed to 70–80% of their volume—this leaves room for solids to settle and liquid to drain besides placing excessive stress on the bag. Follow the manufacturer’s recommendations for fill peak and volume, as these are tailor-made to the bag’s fabric electricity and size.

Post-Loading Practices to Maintain Filtration Efficiency

Loading doesn’t give up when the bag is filled—these post-loading steps make sure filtration continues smoothly:

1. Allow Adequate Drainage Time

Patience is key. After loading, let the Sludge Dewatering Bags take a seat undisturbed to permit full drainage. The time required varies via slurry kind and bag size, however dashing this step consequences in a wetter filter cake that’s more difficult to dispose of or reuse. Monitor the drainage rate—when liquid glide slows to a trickle, the cake is prepared for removal.

2. Inspect and Maintain the Site

While the luggage dewater, test the surrounding area. Ensure Erosion Control Tubes are functioning properly, shooting any runoff and stopping soil erosion. Clear particles from the tubes if wished to keep flow. Also, look at the dewatering baggage for signs and symptoms of harm (e.g., tears, bulging) and tackle small problems right away with patches to forestall similarly problems.

3. Harvest and Reuse/Dispose of Filter Cake

Once dewatering is complete, get rid of the stable filter cake from the bags. Depending on the industry, this cake can be reused (e.g., as fill fabric in construction, as fertilizer in agriculture) or disposed of safely. Empty Dewatering Bags can regularly be reused for a couple of cycles, as lengthy as the geotextile stays intact—this reduces waste and lowers undertaking costs.

Conclusion: Proper Loading = Efficient Dewatering

Maximizing filtration effectivity in slurry dewatering isn’t about high priced equipment—it’s about getting to know the fundamentals of acceptable loading. By grasp slurry characteristics, choosing the proper Dewatering Bags or Sludge Dewatering Bags, and following controlled, even loading techniques, you can appreciably enhance processing time, solids capture, and cost-effectiveness.

When paired with Erosion Control Tubes for web site management, perfect slurry loading creates a holistic dewatering device that’s efficient, environmentally responsible, and effortless to maintain. Whether you’re coping with development sludge, agricultural waste, or mining tailings, these hints will assist you get the most out of your dewatering solutions—turning a messy waste move into manageable, reusable resources. Invest time in appropriate loading, and you’ll see returns in quicker dewatering, much less waste, and a smoother, greater worthwhile process.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province