Troubleshooting Slow Dewatering: Causes and Effective Solutions

Dewatering is a imperative step in construction, wastewater treatment, mining, and environmental remediation projects—efficient water elimination ensures website online stability, reduces undertaking timelines, and complies with environmental regulations. Tools like Dewatering Bags, Erosion Control Tubes, and Polypropylene geotextile tube luggage are broadly used for their capability to separate solids from water whilst containing sediment. However, sluggish dewatering is a frequent frustration that can halt progress, enlarge costs, and compromise task outcomes. This information breaks down the root reasons of sluggish dewatering and affords centered options to restoration efficiency, with a focal point on optimizing the overall performance of your geotextile dewatering systems.

Why Slow Dewatering Happens: Key Causes

Before addressing solutions, it’s vital to diagnose the underlying problems slowing down water removal. Most troubles stem from fabric selection, operational errors, or website online prerequisites that influence how water drains via Dewatering Bags and associated systems.

1. Incompatible Geotextile Material Selection

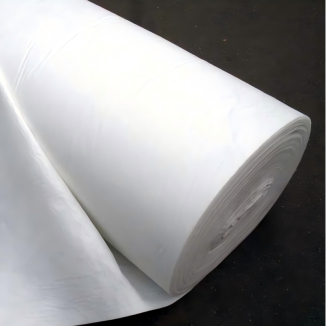

The kind of geotextile used in Polypropylene geotextile tube luggage or Erosion Control Tubes at once impacts dewatering speed. Using a material with too tight a pore shape (e.g., a fine-filter geotextile for high-solids sludge) clogs quickly, whilst overly porous cloth can also let solids escape, forcing rework. For example, a nonwoven geotextile with a low permeability ranking will lure satisfactory particles on the surface, growing a “cake layer” that blocks water flow—this is a frequent difficulty when the usage of typical baggage for industrial sludge dewatering.

2. Overloading Dewatering Systems

Overfilling Dewatering Bags or Erosion Control Tubes with sludge or sediment is a familiar mistake. When baggage are packed too tightly, the fabric interior compacts, decreasing pore house and slowing water drainage. Additionally, including too plenty cloth at as soon as can purpose the geotextile to stretch or deform, narrowing the pathways for water to escape. This is specifically difficult with Polypropylene geotextile tube bags, which depend on even distribution of solids to preserve regular dewatering rates.

3. Poor Site Preparation and Placement

Dewatering structures operate pleasant on flat, well-drained surfaces. Placing Dewatering Bags on uneven ground, gentle soil, or areas with standing water can block drainage stores and lure water internal the bags. Similarly, stacking baggage too excessive or too shut collectively restricts air circulation and water runoff, main to stagnation. For Erosion Control Tubes used in slope dewatering, flawed alignment (e.g., in opposition to the slope gradient) can stop water from flowing out efficiently.

4. High Solids Content or Viscous Sludge

Sludge with excessive concentrations of satisfactory solids (e.g., clay, silt) or natural remember (e.g., meals waste, biosolids) is naturally slower to dewater. These particles clump together, forming a dense matrix that resists water movement. Even notable Polypropylene geotextile tube baggage warfare with viscous sludge, as the satisfactory particles coat the geotextile pores and forestall water from passing through.

5. Inadequate Drainage Aids or Additives

Many dewatering initiatives require chemical or mechanical aids to pace up water removal, but skipping these steps is a frequent oversight. Without flocculants (to clump fantastic particles) or coagulants (to decrease sludge viscosity), water stays trapped in the solids matrix, prolonging dewatering time. This is specially genuine for initiatives the usage of Erosion Control Tubes to deal with wastewater with excessive natural content.

Effective Solutions to Speed Up Dewatering

Once you’ve recognized the reason of sluggish dewatering, these centered options will assist restoration effectivity and maximize the overall performance of your Dewatering Bags, Erosion Control Tubes, and Polypropylene geotextile tube bags.

1. Select the Right Geotextile Material

Match the geotextile to your project’s precise needs:

For high-solids sludge or high-quality particles, select a Polypropylene geotextile tube bag with a medium-to-high permeability ranking (and gorgeous pore size) to stability filtration and drainage.

For wastewater with coarse solids, choose for Erosion Control Tubes with a woven geotextile fabric, which lets in quicker water drift whilst containing large particles.

Consult producers to pick out geotextiles with UV resistance and tear strength—this prevents untimely degradation and continues drainage ability over time.

2. Optimize Loading and Filling Practices

Fill Dewatering Bags and Polypropylene geotextile tube baggage in layers (no extra than 50% of the bag’s potential at once) and permit partial dewatering between fills to stop compaction.

Distribute sludge evenly interior the bags/tubes to make certain uniform water drainage—avoid piling fabric in one spot, which creates dense pockets.

For large-scale projects, use low-pressure pumping structures to fill luggage slowly, lowering turbulence and permitting solids to settle evenly.

3. Improve Site Preparation and Placement

Prepare a flat, compacted base (using gravel or overwhelmed stone) for Dewatering Bags to make certain water drains away from the machine and doesn’t pool underneath.

Space bags/tubes at least 1 foot aside to enable air circulation and water runoff—stack no extra than two layers high to keep away from crushing decrease units.

For slope applications, align Erosion Control Tubes parallel to the slope’s contour and installation a drainage layer (e.g., gravel) under them to channel water away.

4. Treat Sludge to Reduce Viscosity and Solids Clumping

Add flocculants (e.g., anionic or cationic polymers) to sludge earlier than pumping it into Polypropylene geotextile tube bags—these chemical substances bind first-class particles into large clumps, developing large pores for water to escape.

For natural sludge, use lime or alum to increase pH stages and ruin down viscous compounds, enhancing dewatering speed.

Consider pre-filtering sludge to eliminate giant particles (e.g., sticks, rocks) that can block geotextile pores and sluggish drainage.

5. Enhance Drainage with Mechanical Aids

Use vacuum-assisted dewatering structures for Dewatering Bags—applying mild suction to the bag’s floor pulls water out faster, specially for low-permeability sludges.

Install perforated drainage pipes below Erosion Control Tubes to accumulate and redirect water away from the site, stopping reabsorption into the tubes.

Agitate sludge gently (e.g., with a low-speed mixer) earlier than filling to damage up clumps and enhance water separation.

6. Maintain and Monitor Dewatering Systems

Inspect Polypropylene geotextile tube baggage and Erosion Control Tubes often for tears, clogs, or leaks—patch small holes straight away to forestall solids loss and keep drainage.

Remove floor cake layers (accumulated solids) gently with a gentle brush to reopen geotextile pores—avoid the use of sharp equipment that can injury the fabric.

Track dewatering fees (e.g., water quantity eliminated per hour) to perceive slowdowns early and regulate procedures earlier than they influence assignment timelines.

When to Upgrade or Replace Dewatering Systems

If gradual dewatering persists regardless of troubleshooting, it may additionally be time to improve your equipment:

For high-volume projects, change from trendy Dewatering Bags to large Polypropylene geotextile tube baggage (which provide greater floor region for drainage).

For extraordinarily viscous sludge, use Erosion Control Tubes with a dual-layer geotextile (a quality internal layer for filtration and a coarse outer layer for electricity and drainage).

If website prerequisites are persistently moist or cold, pick geotextiles with freeze-thaw resistance to stop cloth degradation and keep performance.

Conclusion

Slow dewatering doesn’t have to derail your project—by diagnosing the root motive and making use of focused solutions, you can optimize the overall performance of Dewatering Bags, Erosion Control Tubes, and Polypropylene geotextile tube baggage to fix efficiency. From choosing the proper geotextile fabric to enhancing website placement and treating sludge, each and every step performs a function in making sure fast, wonderful water removal. By following these guidelines, you’ll minimize downtime, decrease costs, and obtain dependable dewatering outcomes for any project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province