Maximizing Efficiency: Best Practices for Geotube Dewatering Performance

Dewatering is a indispensable technique throughout industries—from building and mining to environmental remediation and wastewater treatment. Efficiently keeping apart solids from beverages now not solely reduces waste extent and disposal prices however also ensures compliance with environmental guidelines and quickens undertaking timelines. Geotube dewatering structures have emerged as a reliable, most economical answer for coping with high-volume sludge, sediment, and contaminated water. However, their overall performance hinges on ideal implementation, from cloth decision to maintenance. In this guide, we’ll discover actionable satisfactory practices to maximize dewatering efficiency, with a center of attention on integrating complementary options like Geobag Dewatering, Geotextile Filter Bag, and Silt Bags For Dewatering.

1. Choose the Right Materials: Matching Geotube and Complementary Products to Your Application

The basis of profitable dewatering lies in deciding on substances tailor-made to your unique waste circulate and assignment goals. Geotube structures matter on high-strength, permeable fabric to maintain solids whilst permitting water to drain, however pairing them with the right complementary merchandise enhances effectivity and longevity.

Key Considerations for Material Selection

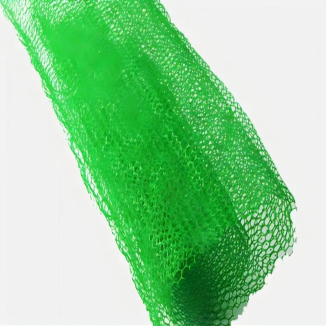

First, analyze the traits of your sludge or sediment: particle size, moisture content, chemical composition, and pH levels. For fine-grained sediments (e.g., clay or silt), a Geotextile Filter Bag with a tight weave is indispensable to forestall solids from escaping whilst facilitating water flow. These baggage act as a secondary filtration layer, shooting micron-sized particles that would possibly in any other case clog the Geotube fabric.

For initiatives dealing with giant volumes of unfastened sediment—such as dredging or development website runoff—Silt Bags For Dewatering are best for pre-treatment. These long lasting luggage entice coarse solids earlier than the waste enters the Geotube system, lowering the danger of clogging and rushing up normal dewatering. They additionally simplify on-site waste administration via concentrating solids in without difficulty portable containers.

Geobag Dewatering solutions, meanwhile, excel in purposes requiring modular, bendy dewatering. These luggage are designed to work in tandem with Geotube systems, particularly in restricted areas or brief projects. When deciding on Geobags, prioritize fabric with excessive tensile electricity and chemical resistance to stand up to aggressive waste streams (e.g., industrial sludge or contaminated groundwater).

Avoid one-size-fits-all approaches: the use of a Geotextile Filter Bag unsuited to particle dimension can lead to both immoderate clogging (too tight) or solids leakage (too loose), each of which limit effectivity and enlarge costs.

2. Prepare the Site for Optimal Drainage and Stability

Site guidance is frequently omitted however fundamental to Geotube dewatering performance. Poorly organized surfaces can reason uneven loading, cloth damage, or insufficient drainage—all of which preclude efficiency.

Site Preparation Steps

Start with the aid of deciding on a level, steady vicinity with desirable drainage. Clear the web page of sharp particles (rocks, metal, branches) that should puncture the Geotube or Geobag Dewatering fabrics. If the floor is gentle or uneven, lay a geotextile base layer to distribute weight evenly and forestall the machine from sinking at some stage in filling.

Ensure desirable slope for drainage: the web page need to grade away from the dewatering place at a 1-2% slope to direct filtered water towards series channels or retention ponds. For initiatives the usage of Silt Bags For Dewatering, function them upstream of the Geotube machine to seize sediments earlier than they attain the principal dewatering structure. This pre-treatment step reduces the load on the Geotube and extends its operational life.

Additionally, reflect onconsideration on environmental factors: if the web page is inclined to heavy rainfall, installation brief covers for the dewatering machine to stop over-saturation. For bloodless climates, pick substances rated for low temperatures to keep away from material brittleness. Proper web site coaching no longer solely boosts effectivity however additionally minimizes the threat of high priced downtime or environmental incidents.

3. Master Installation Techniques for Leak-Proof, Efficient Operation

Incorrect installation is a main reason of dewatering inefficiency. Even the highest-quality Geotube and complementary merchandise will underperform if now not established properly. Follow these strategies to make sure a tight, purposeful system.

Installation Best Practices

First, unroll Geotube fabric cautiously to keep away from tearing or stretching. Ensure seams are aligned and overlapped in accordance to producer recommendations (typically 12-18 inches) to stop leaks. Use well suited fasteners (e.g., hog rings, zip ties) to impervious seams—avoid sharp equipment that ought to injury the fabric.

When integrating Geobag Dewatering, location baggage in a staggered sample to maximize floor place for drainage. Fill luggage steadily (no extra than 50% ability at a time) to forestall overloading and make certain even distribution of solids. For Silt Bags For Dewatering, function them with openings going through the route of flow, and impenetrable them to stakes or frames to forestall moving for the duration of filling.

Properly anxiety the Geotube at some stage in filling to preserve its form and optimize filtration. Overfilling can stretch the fabric, lowering its permeability, whilst underfilling wastes area and extends mission timelines. Use a low-pressure pump to feed sludge into the system—high strain can pressure solids thru the fabric, inflicting clogging or leakage.

Finally, deploy monitoring ports to music water stages and solids accumulation. This approves you to modify filling quotes or function renovation earlier than effectivity drops.

4. Optimize Operation: Control Feed Rates, Monitor Performance, and Adjust as Needed

Even with ideal guidance and installation, ongoing operation is key to maximizing dewatering efficiency. Real-time monitoring and changes make sure the machine adapts to altering waste traits and continues height performance.

Operational Tips

Control feed fees to fit the Geotube’s filtration capacity. Feeding sludge too rapidly overwhelms the fabric, main to clogging and decreased water flow. Feeding too slowly wastes time and will increase labor costs. Aim for a steady, regular glide that approves water to drain as solids accumulate.

Regularly reveal the Geotextile Filter Bag and Silt Bags For Dewatering for symptoms of clogging—such as decreased water go with the flow or bulging. If clogging occurs, gently agitate the luggage or use low-pressure water to rinse the floor (avoid high-pressure washing, which can harm the fabric). For power clogs, exchange filters or rotate baggage to keep throughput.

Track the moisture content material of dewatered solids to gauge efficiency. Target moisture stages (typically 20-40% for disposal or reuse) will range by using application, however regular monitoring helps pick out troubles early. If moisture content material is too high, alter feed rates, take a look at for clogs, or affirm that the Geotextile Filter Bag is excellent sized for the particle load.

Additionally, control the filtered water properly. Collect and take a look at water to make sure compliance with discharge regulations. In some cases, filtered water can be reused for irrigation or manner water, similarly lowering expenses and environmental impact.

5. Implement Routine Maintenance to Extend Lifespan and Efficiency

Regular preservation prevents pricey breakdowns and ensures your dewatering gadget operates efficaciously for its whole lifespan. Neglecting upkeep can lead to material degradation, clogging, or leaks—all of which limit performance and amplify long-term costs.

Maintenance Checklist

Inspect the device day by day at some point of operation: take a look at for tears, leaks, or moving of Geotube or Geobag Dewatering components. Repair small tears straight away with patch kits designed for geotextile fabrics. Replace broken Silt Bags For Dewatering or Geotextile Filter Bag quickly to stop solids leakage or gadget failure.

After dewatering is complete, smooth the device thoroughly. Rinse Geotube fabric and filters with low-pressure water to get rid of residual solids. Dry elements definitely earlier than storing to forestall mildew or mildew growth. Store fabric in a cool, dry vicinity away from daylight and sharp objects.

For long-term projects, agenda periodic cloth checking out to investigate permeability and strength. Over time, publicity to chemical compounds or UV radiation can degrade geotextiles—replacing worn fabric earlier than they fail ensures steady efficiency.

Finally, file all protection activities, together with feed rates, moisture levels, and repairs. This records helps discover tendencies and optimize future dewatering projects.

6. Address Common Challenges: Troubleshoot Clogging, Leakage, and Slow Dewatering

Even with fantastic practices, challenges may also arise. Here’s how to troubleshoot frequent troubles and restoration effectivity quickly.

Troubleshooting Guide

Clogging: If water glide slows dramatically, take a look at the Geotextile Filter Bag and Silt Bags For Dewatering for accrued solids. Rinse or substitute filters, and modify feed costs to decrease solids loading. For fine-grained sludge, think about including a flocculant to mixture particles, making them less difficult to filter.

Leakage: Leaks regularly stem from negative seam alignment or broken fabric. Inspect seams and restore any gaps with extra fasteners or patch kits. If the cloth is torn, change the affected area straight away to forestall environmental contamination.

Slow Dewatering: Slow drainage may additionally end result from mistaken web site slope, overfilling, or incompatible cloth selection. Adjust the website slope, limit fill rates, or change to a Geotextile Filter Bag with greater permeability.

By addressing these troubles promptly, you decrease downtime and hold your dewatering device running at top efficiency.

Conclusion: Elevate Your Dewatering Performance with Proven Best Practices

Geotube dewatering structures provide unparalleled effectivity and versatility, however their success relies upon on cautious cloth selection, website online preparation, installation, operation, and maintenance. By integrating Geobag Dewatering, Geotextile Filter Bag, and Silt Bags For Dewatering into your process—and following the first-rate practices outlined here—you can decrease challenge timelines, decrease costs, and make sure compliance with environmental regulations.

Remember: each venture is unique. Analyze your waste stream, adapt these practices to your precise needs, and display overall performance closely. With the proper approach, your dewatering device will supply consistent, dependable results, supporting you obtain your assignment desires efficaciously and sustainably.

Whether you’re managing development website runoff, mining sludge, or wastewater treatment, these satisfactory practices will maximize the overall performance of your Geotube® dewatering system—turning waste into a manageable, least expensive resource.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province