Longevity Factors: What Affects the Lifespan of Geotextile Cloth?

Introduction: The Importance of Geotextile Cloth Lifespan

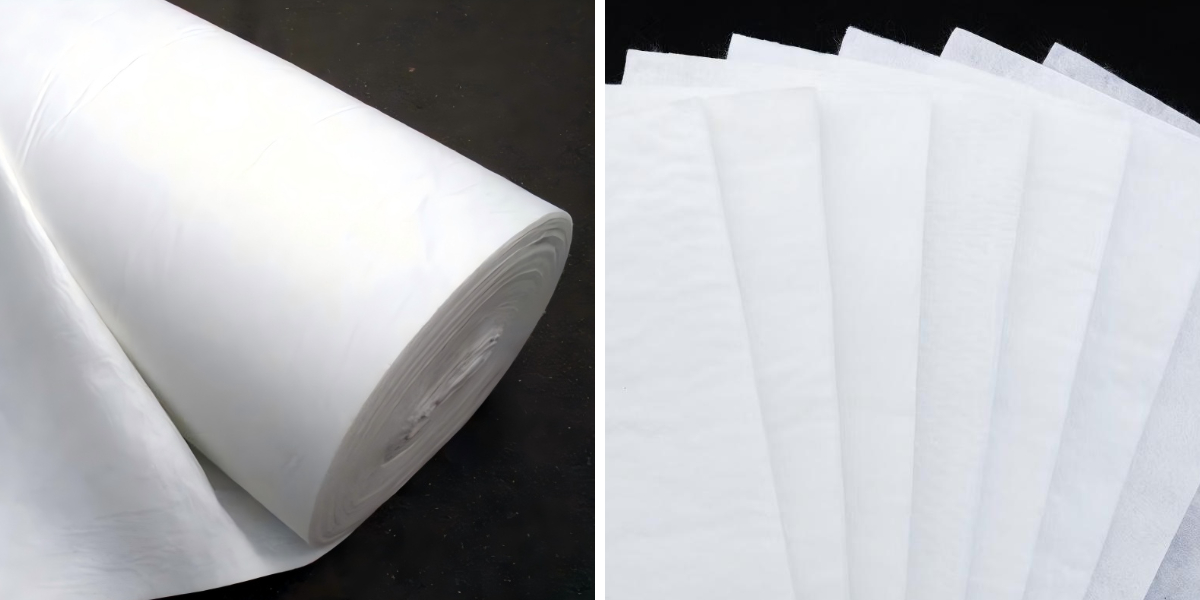

Geotextile cloth, usually referred to as geofabric, is a critical component in civil engineering, agriculture, and environmental projects. From avenue stabilization to erosion control, its potential to withstand time and stress barring extend influences undertaking sturdiness and cost-effectiveness. A geotextile's lifespan can vary from 5 to 50 years, however this variability depends upon on key factors. Understanding these elements helps specialists choose out the proper product and maximize its performance. In this article, we'll discover what influences how prolonged geotextile material lasts, with a focal point on material, environment, and usage.

1. Geo Textile Material: The Foundation of Longevity

The type of geo material cloth is the most important determinant of a geotextile’s lifespan. Manufacturers use polymers like polypropylene (PP), polyester (PET), and polyethylene (PE), every with special properties:

Polypropylene (PP): Affordable and resistant to chemical corrosion, PP geotextiles are regular in brief tasks (5-10 years). However, they are a whole lot much much less UV-resistant, making them unsuitable for long-term exposed applications.

Polyester (PET): PET geotextiles excel in durability, with a lifespan of 20-50 years. Their excessive tensile electrical energy and resistance to UV rays, moisture, and microbial growth make them best for everlasting projects like landfill liners or coastal protection.

Blended Materials: Some geofabrics mix PP and PET to stability cost and longevity, imparting 10-20 years of provider for mid-term duties such as motorway embankments.

Choosing the proper geo textile fabric(https://www.cggeosynthetics.com/high-strength-and/geofabric-bags.html) ensures the geotextile fits the project’s timeline and environmental demands.

2. Environmental Conditions: Nature’s Impact on Durability

Geotextile cloth faces normal publicity to natural elements, which can accelerate degradation:

UV Radiation: Sunlight breaks down polymer bonds over time. PET geotextiles, with inherent UV stabilizers, continue to be much longer than PP in sunny, unshaded areas. For example, a PP geofabric in desert areas might also also additionally degrade in 5 years, at the same time as a PET variant lasts 20+.

Moisture and Temperature: Sustained wetness (e.g., in riverbanks) can purpose hydrolysis in some polymers, however PET resists this greater than PP. Extreme temperature fluctuations, frequent in bloodless climates, can make geotextiles brittle—blended resources regularly take care of this stress more effectively.

Chemical Exposure: Soil pH, industrial runoff, or agricultural fertilizers can corrode geotextiles. Geotextile filter cloth, designed for drainage in chemical-rich environments, makes use of acid-resistant PET to retain overall performance in such conditions.

Assessing the project’s neighborhood weather and soil chemistry is key to selecting a geotextile that resists environmental wear.

3. Mechanical Stress: Wear and Tear from Usage

Geotextiles(https://www.cggeosynthetics.com/geotextile/) suffer bodily stress all through set up and operation, affecting their lifespan:

Installation Damage: Improper handling—such as dragging geofabric over sharp rocks or the usage of excessive tension—can create tears or weaken fibers. A well-installed geotextile, laid with care to keep away from abrasion, retains its structural integrity longer.

Load-Bearing Pressure: In street construction, normal car weight compresses the geotextile. High-tensile PET geotextiles stand up to this strain higher than PP, reducing the chance of untimely failure.

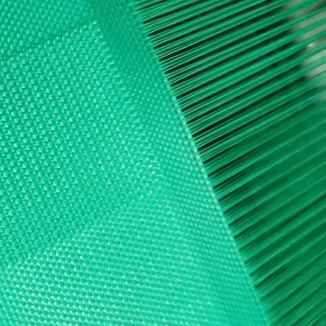

Abrasion: Soil particles, flowing water, or vegetation roots rubbing in opposition to the geotextile can put on down its surface. Geotextile filter cloth, used in drainage systems, regularly includes a bolstered layer to face up to abrasion from sediment-laden water.

Minimizing mechanical stress via ideal set up and material willpower extends a geotextile’s issuer life.

4. Biological Factors: Microbes and Vegetation

Natural organisms can also have an effect on geotextile longevity:

Microbial Degradation: Bacteria and fungi in moist soil feed on herbal components in some geotextiles. Synthetic geo fabric material (PP, PET) resists this, unlike natural fibers like jute, which biodegrade in 1-3 years.

Root Penetration: Aggressive plant roots (e.g., tree roots in slope stabilization) can puncture geotextiles. Reinforced geofabric with a dense weave acts as a barrier, stopping root injury in landscaping or revegetation projects.

For initiatives in biologically active environments, synthetic, non-biodegradable geotextiles are the tremendous choice.

5. Maintenance and Quality: Human Factors in Longevity

Proper care and product fantastic play significant roles:

Manufacturing Quality: High-quality geotextiles, produced with consistent fiber density and weaving, face up to degradation higher than low-grade alternatives. Look for certifications (e.g., ISO standards) to ensure durability.

Inspection and Repair: Regular tests for tears, UV damage, or clogging (in geotextile filter cloth) permit for timely repairs, stopping small troubles from worsening. For example, patching a minor gap in a drainage geofabric continues its filtering feature and avoids soil erosion around the damage.

Investing in splendid substances and routine maintenance at once boosts a geotextile’s lifespan.

Conclusion: Maximizing Geotextile Cloth Lifespan

A geotextile’s longevity depends upon on a combine of material choice, environmental conditions, mechanical stress, herbal factors, and maintenance. By deciding on the right geo material material—such as UV-resistant PET for everlasting projects or geotextile filter cloth for chemical environments—and mitigating stress thru careful set up and upkeep, professionals can make certain their geofabric performs reliably for its supposed lifespan. Understanding these factors transforms geotextiles from effortless materials into long-term assets for any improvement or environmental project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province