How Does Geotextile Cloth Work? Understanding Filtration, Separation, and Stabilization

In civil engineering, construction, and environmental projects, geotextile material is a unsung hero—quietly enhancing durability, reducing costs, and defending ecosystems. This versatile synthetic fabric performs three fundamental functions: filtration, separation, and stabilization—addressing accepted challenges like soil erosion, sediment buildup, and structural failure. But how exactly does it work? This data breaks down the science in the again of geotextile cloth, exploring how its design and material residences permit it to filter water, separate soil layers, and stabilize surfaces. We’ll moreover highlight the role of non woven geotextile fabric and geotextile filter cloth in unique applications, aiding you understand why this cloth is a staple in contemporary improvement and environmental remediation.

What Is Geotextile Cloth, and What Makes It Unique?

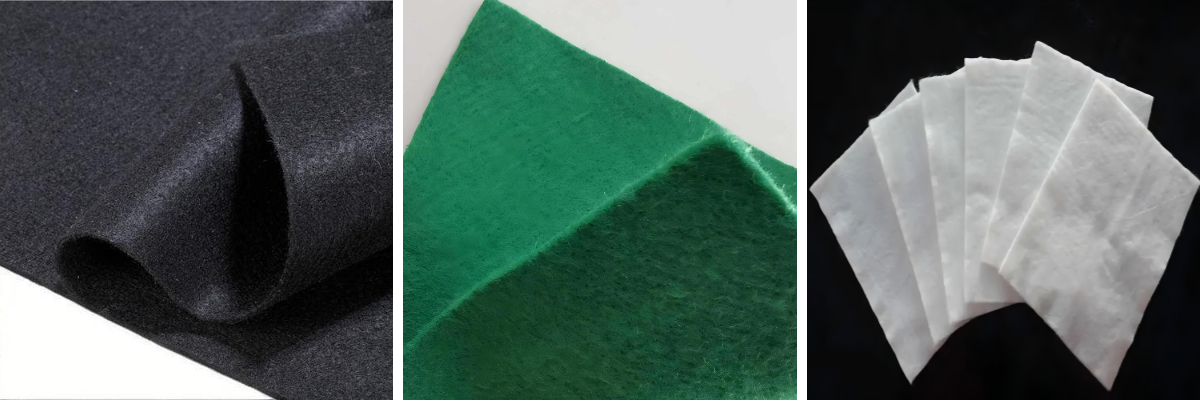

Geotextile cloth is a permeable synthetic material made from polymers like polypropylene, polyester, or polyethylene. Unlike day-to-day cloth, it’s engineered to face up to harsh environmental conditions—UV radiation, chemical exposure, and natural degradation—while maintaining its structural integrity. There are two most vital types: woven and non-woven. Non woven geotextile cloth is made thru bonding fibers jointly (via heat, chemicals, or mechanical processes) to create a porous mat, making it best for filtration and separation. Woven geotextiles, by way of capability of contrast, are made with the aid of way of weaving fibers into a tight grid, imparting increased tensile electrical energy for stabilization applications.

What gadgets geotextile cloth apart is its ability to balance permeability and strength. It lets water pass by using even as trapping solids, putting aside different materials, and reinforcing soil—all barring consisting of excessive weight or bulk. This makes it a budget friendly desire to frequent strategies like gravel filters or concrete barriers.

Function 1: Filtration—How Geotextile Filter Cloth Cleans Water

Filtration is one of the most popular makes use of of geotextile cloth, and geotextile filter material (a specialised variant) is designed specifically for this purpose. The purpose of filtration is to allow water to waft by even as trapping sediment, debris, or contaminants—preventing clogging of drainage buildings and defending water quality.

The Science of Filtration

Geotextile filter material works like a sieve, then again with a twist. Its porous structure (measured by means of way of pore size) traps particles massive than the pores while letting water pass by through. For example, in a drainage ditch, non woven geotextile cloth is placed between the soil and the drainage pipe. As water seeps by way of the soil, the geotextile traps silt and sand, stopping them from getting into the pipe and inflicting blockages. The fabric’s permeability ensures water continues to go with the float freely, preserving drainage efficiency.

The key to quality filtration is matching the geotextile’s pore size to the soil’s particle size. A geotextile filter material with too-small pores will clog quickly, stopping water flow. One with too-large pores will let sediment omit by using through, defeating the purpose. Non woven geotextile material is especially well-suited for filtration due to the reality its random fiber affiliation creates a differ of pore sizes, adapting to special soil types.

Common Filtration Applications

Geotextile filter cloth is used in stormwater administration systems, the vicinity it filters runoff until now than it enters rivers or lakes. It’s moreover used in wastewater treatment, landfill liners, and coastal erosion control—where it traps sediment even as enabling convenient water to drain. In agricultural projects, it traces irrigation ditches to stop soil loss and maintain channels clear.

Function 2: Separation—Keeping Soil Layers Apart

Separation is each and every different indispensable function of geotextile cloth. It prevents numerous resources (like soil and gravel) from mixing, retaining the integrity and standard overall performance of each layer. Without separation, excellent soil particles can migrate into coarse aggregates, reducing drainage and weakening structural stability.

How Separation Works

Imagine a avenue improvement project: the subgrade (native soil) is blanketed with a layer of gravel to assist the pavement. Without geotextile cloth, heavy web site traffic would compress the subgrade, forcing fantastic soil particles into the gravel. This mixes the two materials, reducing the gravel’s drainage attainable and inflicting the avenue to settle. By inserting non woven geotextile material between the subgrade and gravel, the geotextile acts as a barrier. It lets water drain from the subgrade into the gravel on the other hand stops soil particles from migrating, maintaining the layers separate and functional.

The separation attribute relies upon on the geotextile’s tensile electrical energy and permeability. It have to be strong enough to stand up to the weight of the overlying material (like gravel or pavement) barring tearing, while nonetheless enabling water to pass by way of to give up waterlogging.

Common Separation Applications

Beyond avenue construction, geotextile cloth is used for separation in railway embankments (separating soil from ballast), parking hundreds (separating subgrade from combination base), and landscaping (separating soil from decorative stone). It’s moreover used in retaining walls, the area it continues backfill fabric from mixing with the native soil, maintaining the wall’s stability.

Function 3: Stabilization—Reinforcing Soil and Structures

Stabilization is the region geotextile cloth affords electricity to soil or structures, lowering deformation and stopping failure. It distributes loads, will expand soil shear strength, and reinforces susceptible areas—making it critical for slopes, embankments, and easy soil sites.

The Mechanics of Stabilization

When geotextile fabric is placed in soil, it acts as a reinforcement. For example, on a steep slope inclined to erosion, non woven geotextile material is laid over the soil and anchored at the top. The cloth distributes the weight of the soil and any overlying vegetation, reducing the hazard of slope failure. It moreover traps soil particles, stopping erosion even as enabling vegetation to increase through, in a similar way stabilizing the slope.

In soft soil areas (like marshes or wetlands), geotextile cloth is used to create a “reinforced soil mat.” The cloth is laid over the easy soil and blanketed with aggregate, spreading the load over a massive region and stopping the soil from compressing excessively. This technique is regularly used in developing foundations or get entry to roads in remote, low-lying areas.

Common Stabilization Applications

Geotextile fabric is used for slope stabilization in toll street and railway projects, stopping landslides and erosion. It’s moreover used in coastal protection (reinforcing sand dunes), mine reclamation (stabilizing waste piles), and inexperienced infrastructure (reinforcing inexperienced roofs and dwelling walls). Woven geotextiles are normally preferred for stabilization due to their higher tensile strength, then again non woven geotextile material is used in features the area a combination of stabilization and filtration is needed.

Choosing the Right Geotextile Cloth for Your Project

To choose the extraordinary geotextile cloth, mirror onconsideration on your project’s predominant attribute (filtration, separation, stabilization) and environmental conditions:

Filtration: Opt for geotextile filter cloth or non woven geotextile material with pore sizes matched to your soil type. Prioritize permeability and resistance to clogging.

Separation: Choose a lengthy lasting non woven geotextile fabric or woven geotextile with immoderate tensile electrical energy to stand up to overlying loads.

Stabilization: Use woven geotextiles for high-tensile strength needs, or non woven geotextile cloth if filtration is additionally required. Consider UV resistance for out of doorways projects.

Conclusion: The Versatile Workhorse of Construction

Geotextile cloth—from non woven geotextile cloth to geotextile filter cloth—is a versatile fabric that solves some of the most universal challenges in improvement and environmental engineering. Its viable to filter water, separate soil layers, and stabilize structures makes it quintessential for initiatives ranging from roads and railways to stormwater administration and coastal protection.

By understanding how each and every attribute works and identifying on the ideal type of geotextile for your needs, you can decorate challenge durability, decrease renovation costs, and defend the environment. Whether you’re a expert engineer or a DIY enthusiast, geotextile material is a system that can supply reliable, long-lasting results—proving that each and every now and then the most quality selections are the ones that work quietly in the returned of the scenes.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province