How Long Does It Take for a Cement Blanket to Harden?

What is a Cement Blanket?

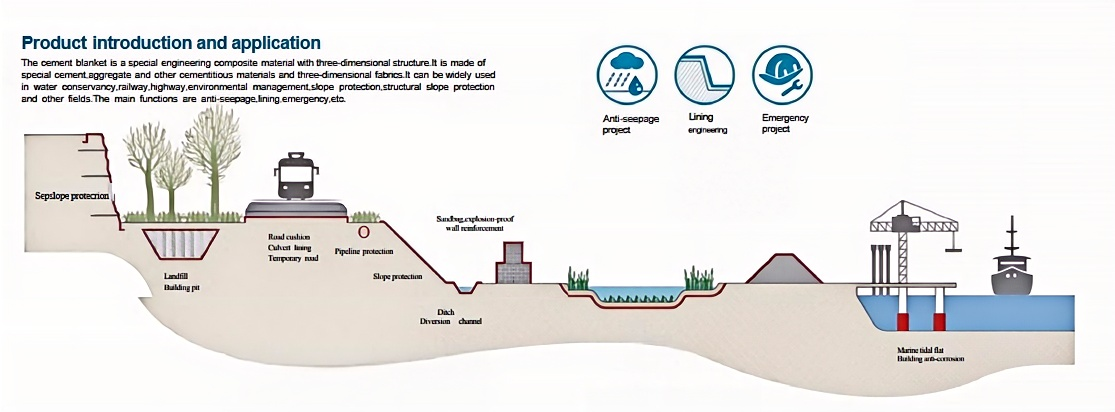

A cement blanket, additionally recognized as concrete fabric or cement canvas, is an modern building cloth that combines the residences of concrete and fabric. It consists of a excessive - power cloth impregnated with dry cementitious materials. This special mixture offers it each flexibility and strength. When dry, the cement blanket can be without difficulty rolled, cut, and formed in accordance to the wishes of the project, a good deal like a normal fabric. It is light-weight and handy to handle, which simplifies the transportation and set up processes. Once hydrated with water, it transforms into a hardened concrete - like structure, imparting the sturdiness and electricity related with usual concrete. This makes it a versatile cloth appropriate for a broad vary of applications, from small - scale DIY initiatives to giant - scale infrastructure developments.

Significance of Knowing the Hardening Time

Understanding how lengthy it takes for a cement blanket to harden is indispensable in a range of fields. In development projects, the hardening time without delay affects the development schedule. For example, if a cement blanket is being used for a foundation or a conserving wall, understanding the hardening time permits contractors to design the subsequent building steps accurately. Premature managing or in addition building on an unhardened cement blanket can lead to harm and compromise the integrity of the structure.

In erosion manipulate applications, such as the usage of Erosion Control Concrete Cloth on slopes to stop soil erosion, the hardening time is equally important. Quick - hardening cement blankets can begin presenting safety towards water runoff and soil displacement sooner, which is necessary in areas susceptible to heavy rainfall or flooding. On the different hand, if the hardening time is too long, the location might also be left susceptible to erosion for an prolonged period. Additionally, in tasks the place time is of the essence, such as emergency repairs or catastrophe - remedy construction, a clear grasp of the hardening time helps in deciding on the most gorgeous cement blanket product to meet the project's time - sensitive requirements.

Understanding Cement Blankets

Composition of Cement Blankets

A cement blanket is a composite fabric with a special composition that contributes to its incredible properties. At its core, it consists of two principal components: a material matrix and dry cementitious materials.

The material used in cement blankets is usually a excessive - electricity artificial or herbal fiber. Synthetic fibers like polyester or polypropylene are famous due to their durability, resistance to rot, and high tensile strength. Natural fibers such as jute can additionally be used in some eco - pleasant versions. The cloth serves as a bendy framework, supplying the cement blanket with its preliminary pliability. This approves it to be without difficulty transported, rolled up, and reduce into quite a number shapes in accordance to the task requirements. It additionally provides to the average power of the hardened structure, an awful lot like the rebar in normal concrete, by way of stopping the cement from cracking and bettering its load - bearing capacity.

The dry cementitious substances impregnated inside the cloth are the key to the hardening process. These substances generally consist of Portland cement, which is the most frequent kind of cement used in construction. Portland cement, when hydrated with water, undergoes a chemical response referred to as hydration. This response leads to the formation of a solid, rock - like mass that offers the cement blanket its hardened strength. Other components may additionally additionally be blanketed in the cementitious mix, such as accelerators to velocity up the hardening technique or retarders to sluggish it down, relying on the particular software requirements. Some cement blankets can also additionally comprise fillers like sand or fly ash, which can enhance the workability of the cement combine and decrease the fee whilst preserving the critical power characteristics.

Types of Cement Blankets (Brief Mention)

There are one of a kind kinds of cement blankets reachable on the market, every designed to meet particular needs. The wellknown cement blanket is appropriate for a extensive vary of regularly occurring - reason applications. It has a primary composition of material and cementitious substances and presents a top balance between price - effectiveness and performance. For example, it can be used for small - scale landscaping projects, such as growing backyard paths or edging flower beds.

The more advantageous cement blanket is engineered with extra facets to face up to greater worrying conditions. It can also have a greater density of cloth fibers or a greater centred combo of cementitious materials. This kind is frequently used in infrastructure projects, like constructing keeping partitions or lining canals, the place increased power and sturdiness are required. In some greater versions, distinctive components are integrated to enhance the resistance to chemical corrosion, making them appropriate for use in industrial areas or close to our bodies of water with excessive salt content.

There are additionally specialised cement blankets designed for particular applications, such as the aforementioned Erosion Control Concrete Cloth. These are optimized to stop soil erosion on slopes and riverbanks. They might also have special surface textures or extra layers to decorate their grip on the soil and higher face up to the forces of water runoff.

The Hardening Process

Chemical Reactions Involved

When a cement blanket comes into contact with water, a collection of complicated chemical reactions commence, in particular the hydration of the cementitious substances inside it. The major issue of the cement in the blanket is frequently Portland cement, which carries compounds such as tricalcium silicate , dicalcium silicate, tricalcium aluminate , and tetracalcium aluminoferrite .

When water is added, reacts swiftly with water. This response is exothermic, releasing heat. The product , additionally regarded as calcium - silicate - hydrate (C - S - H) gel, is the most important binding agent that offers the hardened cement its strength. The calcium hydroxide is additionally a by using - product.

additionally reacts with water, though at a slower rate. This response contributes to the lengthy - time period electricity improvement of the cement blanket.

reacts very rapidly with water in the presence of gypsum (which is regularly brought to the cement combine to manipulate the placing time). . If there is no gypsum present, would react with water to structure a gelatinous product that may want to purpose the cement to set too quickly, which is no longer perfect for most applications.

These chemical reactions seriously change the in the beginning smooth and pliable cement blanket into a hard, long lasting structure. The formation of the C - S - H gel creates a robust bond between the cement particles and the cloth matrix of the cement blanket, comparable to how the mortar binds the bricks in a brick - wall structure, giving the cement blanket its hardened properties.

Stages of Hardening

The hardening method of a cement blanket can be divided into various awesome stages, every with its personal traits and time frames.

Initial Wetting and the Start of Reaction (0 - 30 minutes approximately)

When water is first utilized to the cement blanket, it rapidly penetrates the material and comes into contact with the dry cementitious materials. This preliminary stage is marked via the absorption of water by using the cement particles. The water starts to dissolve the soluble elements of the cement, initiating the hydration reactions. At this point, the cement blanket nevertheless retains some flexibility, however the floor may also begin to sense barely cheesy as the initial chemical reactions commence to take place.

Initial Set (30 minutes - four hours approximately)

The preliminary set is the first enormous stage of hardening. During this period, the hydration reactions progress, and the cement blanket starts offevolved to lose its plasticity. The C - S - H gel starts offevolved to structure and grow, growing a community of bonds inside the material. The cement blanket will become stiffer, and it is no longer viable to without problems reshape it. However, it nonetheless does now not have full-size electricity at this stage. In the case of a cement blanket used for a small - scale DIY task like growing a backyard path, taking walks on it all through the preliminary set stage would in all likelihood reason harm to the shape as it is now not but sturdy sufficient to guide any considerable load.

Final Set (4 - 12 hours approximately)

As the hydration reactions continue, the cement blanket reaches its ultimate set. By this stage, the C - S - H gel community has grow to be extra great and robust. The cement blanket has developed a considerable quantity of electricity and can stand up to some mild handling. For example, in an erosion manage assignment the use of Erosion Control Concrete Cloth, the blanket can begin to withstand the forces of minor water runoff at this stage. However, it is nonetheless now not at its full - power capacity, and heavy masses or affects must be avoided.

Hardening and Strength Development (12 hours - 28 days)

After the ultimate set, the cement blanket continues to harden and achieve energy over time. The hydration reactions are nevertheless ongoing, though at a a great deal slower rate. In the first few days, the power of the cement blanket will increase rapidly. By 7 days, it has normally carried out a sizeable element of its remaining strength, possibly round 70 - 80% relying on a number elements such as the kind of cement, temperature, and humidity. Over the subsequent few weeks, up to 28 days, the power continues to strengthen till it reaches its most plan strength. During this lengthy - time period hardening phase, the cement blanket turns into extra and greater resistant to exterior forces, whether or not it is the weight of soil in a protecting wall software or the have an effect on of water in a water - maintaining structure.

How Long Does it Take to Harden?

General Hardening Timeframe

In widely wide-spread conditions, a cement blanket generally takes about 24 - forty eight hours to attain a country the place it has enough power for most mild - to - average applications. After this preliminary hardening period, the cement blanket can withstand minor influences and mild loads. For example, in a small - scale domestic backyard challenge the place a cement blanket is used to create a easy path, after 24 - forty eight hours, it have to be association adequate that mild foot visitors will now not harm it. However, it is vital to observe that this is a time-honored estimate, and the real hardening time can range drastically primarily based on numerous factors.

Variances Based on Conditions

Environmental Temperature: Temperature performs a integral function in the hardening technique of a cement blanket. Higher temperatures speed up the chemical reactions concerned in the hydration of the cementitious materials. In heat climates with temperatures round 25 - 30°C (77 - 86°F), the hardening method can be enormously fast. The multiplied kinetic electricity at greater temperatures permits the water molecules to react greater shortly with the cement compounds. For instance, in a summer time development challenge in a tropical region, a cement blanket may attain its preliminary hardening stage inside 24 hours or even less. On the different hand, in bloodless temperatures, in particular beneath 5°C (41°F), the chemical reactions gradual down considerably. The water may also even freeze at extraordinarily low temperatures, halting the hydration procedure completely. In a wintry weather development venture in a bloodless - local weather area, the hardening time should be prolonged to forty eight hours or more, and extraordinary measures such as the use of heated water for hydration or presenting insulation would possibly be required to make certain suited hardening.

Humidity: Humidity degrees in the surroundings additionally influence the hardening time. High humidity can gradual down the evaporation of water from the cement blanket, which in flip can gradual down the hardening process. When the air is very humid, the water inside the cement blanket stays in a liquid nation for a longer period, and the chemical reactions proceed at a extra leisurely pace. In a coastal place with excessive humidity levels, say round eighty - 90% humidity, the hardening of a cement blanket might also take nearer to the higher give up of the 24 - forty eight - hour range. Conversely, in dry environments with low humidity, such as deserts the place humidity can be as low as 10 - 20%, the water in the cement blanket evaporates extra rapidly. This can purpose the cement to set and harden extra quickly, doubtlessly decreasing the hardening time to the decrease give up of the 24 - forty eight - hour vary or even less. However, speedy evaporation in very dry prerequisites can additionally lead to troubles such as cracking if the cement blanket dries out too shortly earlier than the chemical reactions are completely completed.

Cement Blanket Thickness: The thickness of the cement blanket is every other massive factor. Thicker cement blankets have greater cementitious materials and a higher extent of water required for entire hydration. As a result, they typically take longer to harden. A thinner cement blanket, possibly with a thickness of 5 - 10 mm, will have much less fabric to hydrate and will harden incredibly quicker in contrast to a thicker one. For example, a 5 - mm - thick cement blanket used for a small - scale ornamental mission would possibly attain a adequate hardening nation inside 24 hours. In contrast, a 20 - mm - thick cement blanket used for a extra giant conserving wall software will want extra time, probably nearer to forty eight hours or even longer in some cases, as the hydration manner has to penetrate deeper into the thicker layer of cementitious material.

Comparing with Traditional Concrete (Optional)

Concrete Cloth and Traditional Concrete

Concrete fabric gives various wonderful variations in contrast to usual concrete, specifically when it comes to hardening time, building convenience, and utility scenarios.

In phrases of hardening time, common concrete generally requires a enormously lengthy time to attain its preliminary and closing set. For giant - scale concrete pours, such as these for constructing a multi - story building's foundation, it can take days for the concrete to set to a factor the place it can help in addition building activities. The hydration system in ordinary concrete is a complicated chemical response that relies upon on elements like the combine ratio, temperature, and humidity. In contrast, concrete material usually has a quicker preliminary hardening time. As cited earlier, underneath everyday conditions, it can attain a kingdom appropriate for mild - to - average functions inside 24 - forty eight hours. This faster hardening time can extensively pace up the development schedule, mainly in initiatives the place time is of the essence.

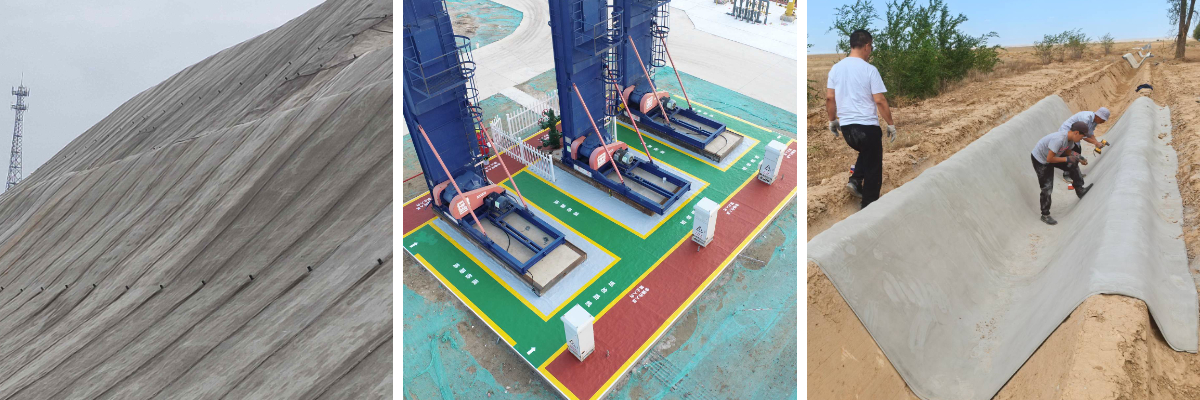

When it comes to development convenience, ordinary concrete requires a lot of heavy gear for mixing, transporting, and placing. A concrete mixer is wanted to combination the cement, aggregates, and water, and then specialised vans are used to transport the sparkling concrete to the building site. Pouring and leveling the concrete frequently contain the use of vibrators to make certain perfect compaction. In contrast, concrete fabric is light-weight and bendy when dry. It can be effortlessly carried and unrolled on - site. It can be reduce to dimension with easy equipment like scissors or a utility knife, and the hydration technique is as easy as making use of water, either with the aid of spraying or soaking. This makes it an best desire for small - scale projects, DIY enthusiasts, or tasks in far flung areas the place get admission to to heavy development tools is limited.

In phrases of software scenarios, ordinary concrete is nicely - suitable for giant - scale, excessive - load - bearing buildings such as skyscrapers, giant bridges, and industrial buildings. Its lengthy - time period electricity and sturdiness make it appropriate for withstanding heavy hundreds and environmental stresses over time. Concrete cloth, whilst additionally durable, is frequently used in purposes the place the capacity to conform to irregular shapes is important. It can be used for developing ornamental factors in gardens, like curved backyard paths or small - scale holding walls. It is additionally a excellent choice for erosion manage on slopes the usage of Erosion Control Concrete Cloth, the place its flexibility approves it to be without difficulty utilized to the uneven terrain.

Cement Canvas and Traditional Concrete

Cement canvas, which is comparable to concrete cloth, additionally has great variations from normal concrete, mainly in phrases of hardening time and development in complicated terrains.

Regarding hardening time, cement canvas has an gain over regular concrete in sure situations. Traditional concrete, as formerly stated, has a fantastically gradual hardening process, in particular in massive - scale applications. Cement canvas, on the different hand, can harden extra swiftly in some cases. For example, in emergency restore projects, such as fixing a broken avenue or a small - scale infrastructure in a catastrophe - affected area, cement canvas can be shortly deployed and hydrated. It can attain a usable energy in a depend of hours to a couple of days, relying on the conditions, permitting for a quicker restoration of the broken shape in contrast to ready for common concrete to set.

In phrases of development in complicated terrains, common concrete faces enormous challenges. In mountainous areas, for instance, transporting the integral concrete substances and heavy tools can be extraordinarily hard due to the tough and inaccessible terrain. Pouring and leveling concrete on steep slopes is additionally a complicated assignment that requires one of a kind strategies and gear to stop the concrete from flowing or now not placing evenly. Cement canvas, however, is plenty extra adaptable. Its flexibility permits it to be effortlessly carried to challenging - to - attain areas. It can be draped and formed to match the contours of the terrain, whether or not it is a steep slope or an irregular - formed surface. In erosion manage tasks on hilly or mountainous areas the usage of Erosion Control Concrete Cloth, cement canvas can be utilized extra correctly than usual concrete, imparting rapid safety in opposition to soil erosion through hardening tremendously shortly as soon as hydrated. This adaptability to complicated terrains makes cement canvas a treasured choice to common concrete in many specialised development and environmental safety projects.

Applications Benefiting from Quick Hardening

Erosion Control Concrete Cloth

Erosion Control Concrete Cloth is a specialised structure of cement blanket that performs a fundamental function in stopping soil erosion. In areas such as riverbanks, slopes, and coastal regions, the hazard of soil displacement due to water runoff and wave motion is constant. The speedy - hardening property of Erosion Control Concrete Cloth is a tremendous gain in these situations.

When utilized to a slope, for example, the cement blanket can be shortly hydrated and begin to harden inside a tremendously brief time, regularly inside the 24 - forty eight - hour commonplace hardening timeframe. As it hardens, it types a long lasting and flexible barrier that adheres to the soil surface. This barrier resists the forces of water flowing down the slope, stopping the soil particles from being washed away. The material factor of the cement blanket affords extra grip on the soil, similarly bettering its effectiveness in erosion control.

In riverbank protection, Erosion Control Concrete Cloth can be established to defend in opposition to the erosive electricity of flowing water. Once hardened, it can stand up to the have an impact on of waves and the steady motion of water, keeping the integrity of the riverbank and stopping collapse. The capacity to harden shortly is fundamental right here due to the fact it approves for instantaneous protection. In areas susceptible to surprising heavy rainfall or flash floods, ready for a gradual - hardening cloth to set should imply the distinction between defending the land and struggling big erosion damage.

Other Construction Applications

In emergency restore projects, the rapid - hardening nature of cement blankets is invaluable. For instance, when a area of a street has been broken due to a pothole or a small - scale landslide, a cement blanket can be swiftly deployed. It can be reduce to size, hydrated, and begin to harden inside a few hours. This permits for a speedy restoration of the road's functionality, minimizing disruptions to traffic. In comparison, common concrete restore strategies would require extra time for the concrete to mix, transport, and set, inflicting longer - time period inconveniences.

Small - scale constructing initiatives additionally advantage from the rapid - hardening property of cement blankets. A DIY fanatic constructing a small shed basis can use a cement blanket. It can be without difficulty laid out, hydrated, and inside a day or two, it will have hardened adequate to aid the development of the shed. This reduces the universal development time and lets in for a greater environment friendly mission completion. In addition, in far flung areas the place get admission to to giant - scale development tools and equipped - combine concrete is limited, the ease of use and speedy - hardening characteristics of cement blankets make them an best desire for small - scale infrastructure building, such as constructing a easy protecting wall or a small - scale water - conserving structure.

Tips for Ensuring Proper Hardening

Moisture Management

Moisture administration is of utmost significance all through the hardening manner of a cement blanket. Maintaining the proper quantity of moisture is imperative for the suitable development of the hydration reactions. When the cement blanket is first hydrated, it wants a adequate quantity of water to initiate and maintain the chemical reactions that lead to hardening. If the water evaporates too quickly, specifically in dry and warm conditions, the hydration technique can be disrupted. The lack of water can forestall the cement compounds from wholly reacting, ensuing in a weaker closing product. This can lead to problems such as cracking, decreased strength, and an common compromised structure.

To forestall this, measures can be taken to maintain moisture. One frequent technique is to cowl the cement blanket with a plastic sheet or a damp burlap material after hydration. This acts as a barrier, decreasing the fee of evaporation and permitting the hydration reactions to appear extra smoothly. In areas with excessive humidity, on the different hand, care have to be taken to make sure that immoderate moisture does no longer accumulate. Standing water on the floor of the cement blanket can dilute the cementitious substances and have an effect on the first-class of the hardened product. Proper drainage and ventilation, if possible, can assist in managing the moisture tiers in such situations.

Temperature Considerations

The environmental temperature in the course of the set up and hardening of a cement blanket has a vast influence on the hardening system and the closing satisfactory of the product. Cement blankets are fantastic hooked up and allowed to harden inside a precise temperature range. Temperatures between 10 - 25°C (50 - 77°F) are commonly viewed top of the line for the ordinary progression of the hydration reactions.

In severe heat, above 30°C (86°F), the chemical reactions can speed up too rapidly. This can purpose the cement blanket to dry out too quickly, main to cracking and decreased strength. The excessive temperature can additionally reason the water to evaporate prematurely, disrupting the hydration process. To mitigate these problems in warm weather, it might also be imperative to moist the place the place the cement blanket is to be established previously to cool the surface. Spraying the cement blanket with water at normal intervals in the course of the preliminary hardening degrees can additionally assist in retaining the proper moisture content material and controlling the temperature - associated acceleration of the reactions.

Conversely, in bloodless temperatures, specially beneath 5°C (41°F), the hydration reactions sluggish down significantly. At temperatures shut to or under freezing, the water inside the cement blanket can freeze. When water freezes, it expands, which can purpose inside damage to the shape of the cement blanket, such as cracking and a loss of bond between the cement and the cloth matrix. In bloodless - climate conditions, it is beneficial to use warm water for hydrating the cement blanket. Insulating the location the place the cement blanket is set up can additionally assist in preserving a greater temperature and permitting the hydration reactions to proceed at a practical pace. Special additives, such as antifreeze agents, may additionally be brought to the cement combine in extraordinarily bloodless conditions, however these ought to be used with warning as they can additionally have an effect on different homes of the cement blanket.

Conclusion

Recap of Key Points

In summary, the hardening time of a cement blanket is a necessary issue in its profitable application. Under regular conditions, it commonly takes 24 - forty eight hours to attain a kingdom appropriate for mild - to - average applications, however this can range substantially relying on environmental temperature, humidity, and the thickness of the cement blanket. The hardening technique includes complicated chemical reactions, with the hydration of cementitious materials being the key, and progresses thru wonderful ranges from preliminary wetting to lengthy - time period power development.

Compared to usual concrete, cement blankets provide blessings such as quicker hardening instances in some instances and higher comfort in coping with and application, in particular in small - scale tasks and complicated terrains. Applications like erosion manage the usage of Erosion Control Concrete Cloth and emergency restore tasks advantage radically from the rapid - hardening property of cement blankets. To make certain suitable hardening, moisture administration and temperature issues are essential. Maintaining the proper moisture degree and heading off excessive temperatures can forestall problems like cracking and make sure the full improvement of the cement blanket's strength.

Future Outlook

As technological know-how continues to advance, the future of cement blankets in the development and erosion manipulate industries appears promising. Research and improvement efforts may additionally lead to the introduction of cement blankets with even extra optimized hardening instances and greater properties. These enhancements should similarly enlarge their functions in a number of fields. For example, in the development of sustainable buildings, cement blankets would possibly be used extra drastically due to their especially speedy set up and hardening, lowering building time and probably minimizing environmental impact. In erosion control, they ought to grow to be the go - to answer in extra regions, imparting fine and fast safety in opposition to soil erosion.

We inspire greater human beings in the construction, DIY, and environmental safety sectors to discover the use of cement blankets. Understanding their hardening instances and acceptable utility strategies can open up new chances for environment friendly and value - high quality venture execution. Whether it is a small - scale domestic enchancment challenge or a massive - scale infrastructure development, cement blankets have the workable to provide revolutionary options that meet the needs of current building and environmental management.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province