How to Choose the Right Geotextile Cloth for Drainage Systems

Drainage structures are the unsung heroes of construction, landscaping, and infrastructure projects—they forestall waterlogging, guard structural integrity, and retain soil quality. But a drainage gadget is solely as dependable as the substances that make it up, and geotextile material stands out as a integral component. Specifically designed to filter, separate, and drain water whilst preserving soil, the proper geotextile material can make or destroy your drainage system’s performance.

This information breaks down how to choose the best geotextile fabric for your drainage needs, with a focal point on key elements like fabric type, permeability, and durability. We’ll additionally spotlight necessary phrases like geo fabric drainage, fantastic non woven geotextile fabric, and geotextile for roads to assist you navigate product selections and align your preference with mission goals.

Why Geotextile Cloth Matters for Drainage Systems

Before diving into selection, it’s crucial to recognize why geotextile fabric is non-negotiable for nice drainage. Unlike normal fabric, geotextile material is engineered to stability two core functions: filtering soil particles (to stop clogging) and permitting water float (to make sure suited drainage). Without it, drainage structures hazard blockages from sediment, main to standing water, soil erosion, and even structural damage.

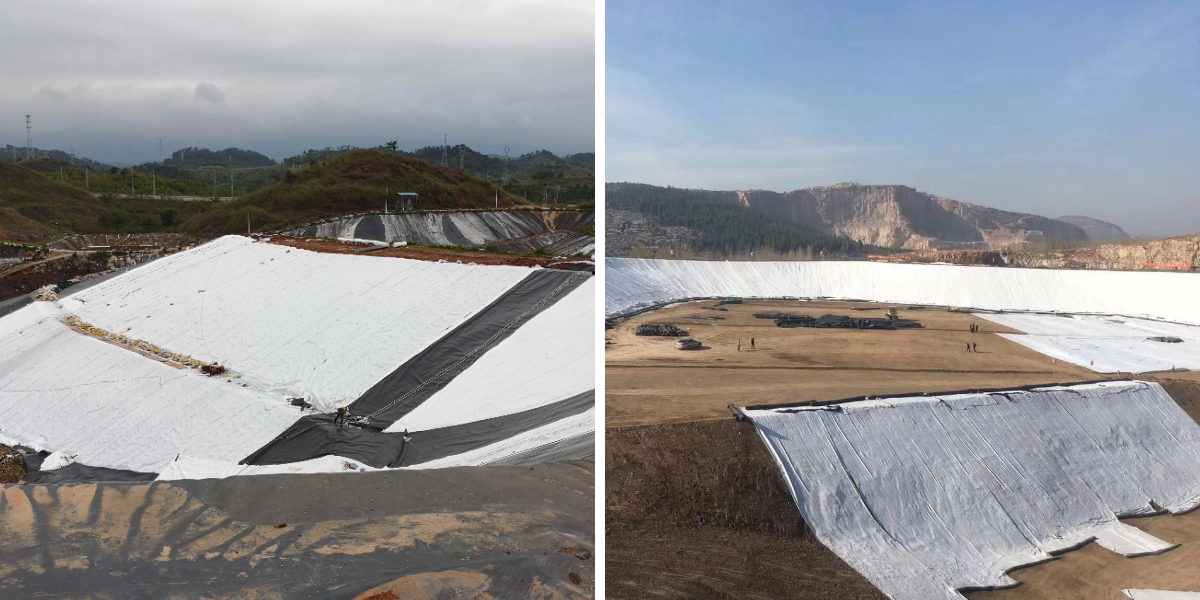

Geo material drainage merchandise act as a barrier between soil and drainage factors (like pipes or gravel). For example, in a French drain, geotextile fabric wraps round gravel to give up great soil from seeping in and clogging the gaps—keeping water flowing freely. In large tasks like avenue construction, geotextile for roads now not solely helps drainage however additionally reinforces the street base, stopping untimely put on from water damage.

Choosing the incorrect geotextile material (e.g., one with low permeability or negative soil retention) can lead to luxurious issues: prevalent maintenance, device replacements, or even challenge delays. That’s why prioritizing the proper specs—starting with fabric type—is key.

Key Factors to Evaluate When Selecting Geotextile Cloth for Drainage

Not all geotextile cloths are created equal. To locate the fantastic in shape for your drainage system, center of attention on these 4 fundamental factors, every tied to overall performance and compatibility with phrases like nice non woven geotextile material and geo fabric drainage.

1. Material Type: Woven vs. Non-Woven Geotextile

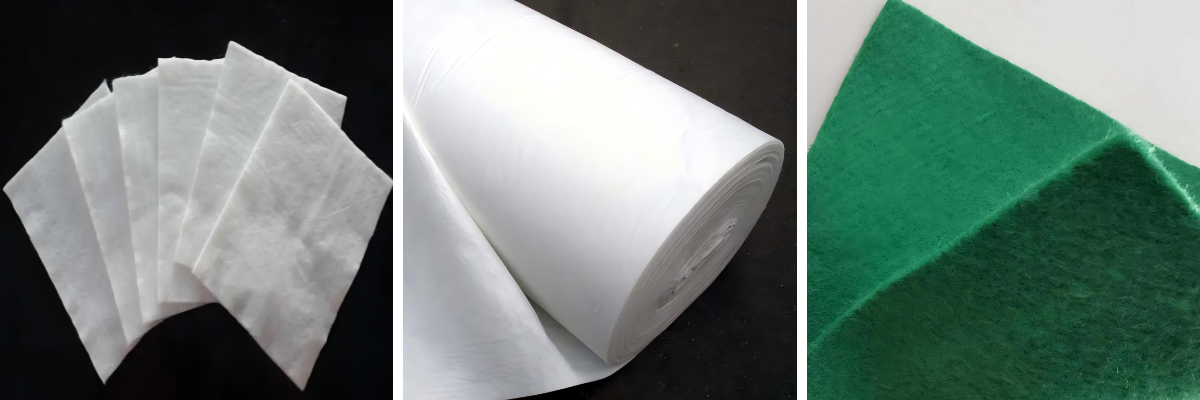

The first selection is between woven and non-woven geotextile—each serves awesome drainage needs, and exceptional non woven geotextile material is frequently the pinnacle preference for most drainage applications.

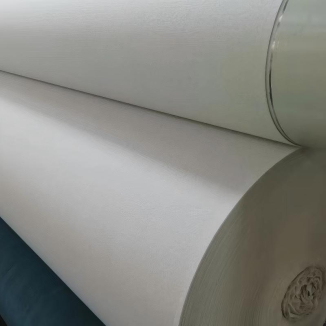

Non-Woven Geotextile: Made by means of bonding artificial fibers (polypropylene or polyester) into a porous mat, non-woven geotextile excels at filtration and drainage. It has excessive permeability, traps nice soil particles barring clogging, and is bendy sufficient to conform to uneven surfaces. This makes it the excellent non woven geotextile cloth for tasks like residential drainage (French drains, yard grading), landscaping, and even mild industrial work. For example, a non-woven polypropylene geotextile with 80% porosity is perfect for draining extra water from flower beds or lawns.

Woven Geotextile: Created by means of weaving artificial threads into a tight grid, woven geotextile presents greater tensile electricity however lower permeability. It’s better perfect for heavy-duty initiatives the place reinforcement is key, such as geotextile for roads (to stabilize avenue bases and drain water from under asphalt) or large-scale development sites. However, its tighter weave ability it may also now not filter as correctly as non-woven options—making it much less perfect for small-scale drainage the place soil retention is critical.

For most drainage-focused tasks (not simply reinforcement), great non woven geotextile material is the go-to, thanks to its stability of filtration and permeability.

2. Permeability (Water Flow Rate)

Permeability—measured in liters per rectangular meter per 2d (L/m²·s)—dictates how rapidly water can pass by via the geotextile cloth. This is the spine of geo material drainage performance: too low, and water pools; too high, and soil particles wash away.

Residential Drainage (e.g., French Drains, Gutters): Aim for permeability between 5–10 L/m²·s. This ensures water drains quick sufficient to stop pooling however gradual adequate to lure satisfactory soil. The great non woven geotextile material for these tasks commonly falls in this range.

Commercial/Infrastructure (e.g., Roads, Parking Lots): For geotextile for roads, permeability must be 8–15 L/m²·s. Roads want to drain giant volumes of water rapidly to keep away from cracks from freezing or water pressure—woven or high-performance non-woven geotextiles work here.

Wet or Clay Soils: If your website has slow-draining soil (like clay), decide for greater permeability (10+ L/m²·s) to keep away from waterlogging. Non-woven geotextile is perfect here, as its porous shape won’t get clogged by way of clay particles.

Always test permeability specs—avoid geotextiles labeled “low permeability” for drainage systems, as they’ll defeat the purpose.

3. Soil Retention (Filter Opening Size)

Filter opening measurement (measured in millimeters or microns) determines the smallest soil particle the geotextile can trap. For geo material drainage, this prevents sediment from clogging drainage pipes or gravel layers.

Sandy Soils: Sandy soil has large particles, so a geotextile with 0.1–0.3mm openings works. It retains sand whilst letting water flow.

Loamy/Clay Soils: These have best particles, so select openings of 0.05–0.1mm. The pleasant non woven geotextile material for clay soils frequently has smaller openings to give up first-class clay from seeping through.

Mixed Soils: For websites with a combine of sand and clay, seem to be for geotextiles with “graded” openings (e.g., 0.08–0.2mm) to stability retention and drainage.

A frequent mistake is deciding on a geotextile with too-large openings—this leads to sediment buildup in drainage pipes, requiring high-priced cleaning.

4. Durability and Environmental Resistance

Drainage structures are uncovered to the factors (UV rays, moisture, chemicals), so sturdiness is non-negotiable. Look for these features:

UV Resistance: Outdoor initiatives want geotextiles handled for UV safety (ASTM D4355 certified). Polypropylene non-woven geotextiles are naturally UV-resistant, making them a pinnacle preference for geo fabric drainage in sunny areas.

Chemical Resistance: For industrial websites or areas with contaminated soil, pick out geotextiles resistant to acids, alkalis, or salts. Polyester non-woven or woven geotextiles excel here.

Abrasion Resistance: If the geotextile will be in contact with rocks or heavy gear (e.g., geotextile for roads), decide for a thick (≥2mm) non-woven or woven cloth to keep away from tearing.

Durable geotextiles closing 5–15 years, decreasing substitute expenses and maintenance.

Step-by-Step Guide to Choosing Geotextile Cloth for Drainage

Follow this actionable technique to align your desire with venture needs, the use of geo material drainage, great non woven geotextile fabric, and geotextile for roads as guideposts.

Step 1: Assess Your Project Type and Site Conditions

Start by way of defining the scope and environment:

Project Scale: Small (residential French drain) vs. massive (road drainage). Small tasks regularly use exceptional non woven geotextile fabric, whilst massive initiatives may additionally want woven selections for reinforcement.

Soil Type: Sandy, loamy, or clay—this dictates filter opening size.

Climate: Sunny (prioritize UV resistance) vs. wet (prioritize excessive permeability).

Drainage Volume: Low (lawn) vs. excessive (road or parking lot)—higher extent wants greater permeability.

Example: A residential French drain in a rainy, sunny location with clay soil would want a UV-resistant, non-woven geotextile (permeability eight L/m²·s, opening measurement 0.08mm).

Step 2: Match Material to Project Goals

Define your pinnacle priority—drainage, filtration, or reinforcement—and choose accordingly:

Priority: Drainage + Filtration: Choose first-class non woven geotextile cloth (polypropylene or polyester).

Priority: Reinforcement + Drainage: Opt for woven geotextile (ideal for geotextile for roads or heavy construction).

Priority: Eco-Friendliness: Look for biodegradable non-woven geotextiles (great for landscaping or restoration projects).

Step 3: Verify Specs and Certifications

Reputable producers supply clear specs and certifications. Check for:

Permeability and filter opening dimension (no indistinct phrases like “good drainage”).

UV and chemical resistance certifications (ASTM or ISO standards).

Tensile power (for reinforcement needs—e.g., ≥10 kN/m for geotextile for roads).

Avoid merchandise with lacking or untested specs—they’re a hazard to your drainage system.

Step 4: Compare Costs vs. Long-Term Value

While pleasant non woven geotextile material might also price barely greater upfront than low-quality options, it saves cash long-term by way of decreasing maintenance. For example:

A 0.50/sqftnon−wovengeotextilelasts10years,whilea

0.30/sq feet lower priced choice wants alternative after two years—costing extra over time.

For massive tasks like geotextile for roads, investing in long lasting woven or high-performance non-woven material prevents high priced avenue repairs later.

Real-World Applications: Geotextile Cloth in Drainage Systems

Seeing how geotextile fabric performs in actual tasks helps validate your choice. Below are frequent use instances presenting geo fabric drainage, first-rate non woven geotextile fabric, and geotextile for roads.

1. Residential French Drain Installation

Project: A house owner in Oregon wanted to restoration a waterlogged outside (clay soil, heavy rainfall).

Geotextile Chosen: Non-woven polypropylene (permeability 9 L/m²·s, opening dimension 0.07mm, UV-resistant).

Why: Non-woven material filters clay particles whilst draining rainwater; UV resistance handles Oregon’s sunny summers.

Result: No extra standing water—water drains 3x quicker than before, and the geotextile stays intact after three years.

2. Road Drainage for a Suburban Highway

Project: A 5-mile motorway extension in Texas (hot, sunny, with occasional heavy rains).

Geotextile Chosen: Woven polyester (permeability 12 L/m²·s, tensile energy 15 kN/m, chemical-resistant).

Why: Woven material reinforces the street base whilst draining rainwater; polyester resists Texas warmth and avenue chemicals.

Result: No water-related potholes after two years; renovation expenses decreased by way of 40% in contrast to roads except geotextile.

3. Landscaping Drainage for a Commercial Park

Project: A park in Florida wanted drainage for flower beds and walkways (sandy soil, ordinary rain).

Geotextile Chosen: Non-woven polyester (permeability 7 L/m²·s, opening dimension 0.2mm, abrasion-resistant).

Why: Non-woven material retains sand whilst draining rain; polyester resists moisture and foot site visitors abrasion.

Result: Flower beds continue to be dry, and walkways have no puddles—even after tropical downpours.

Common Mistakes to Avoid

Steer clear of these blunders to make certain your geo fabric drainage device works seamlessly:

Choosing the Wrong Material: Using woven geotextile for a small residential drain (it’s too impermeable).

Ignoring Filter Opening Size: Using massive openings for clay soil (leads to clogging).

Skipping UV Resistance: Using non-UV-treated geotextile outside (it degrades in 6–12 months).

Prioritizing Price Over Quality: Buying less expensive geotextile that tears or clogs shortly (costs extra to replace).

Conclusion: Invest in the Right Geotextile Cloth for Long-Lasting Drainage

Choosing the proper geotextile fabric for drainage structures isn’t simply about choosing a fabric—it’s about aligning specs with your project’s soil, climate, and goals. Whether you want geo material drainage for a backyard, quality non woven geotextile material for landscaping, or geotextile for roads for infrastructure, focusing on fabric type, permeability, soil retention, and sturdiness will make certain success.

Remember: A well-chosen geotextile material reduces maintenance, protects your task from water damage, and saves cash over time. By following this guide, you’ll pick out a product that continues your drainage gadget flowing smoothly—now and for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province