How to Choose the Right Geocell Material: PP vs. HDPE Geocells Explained

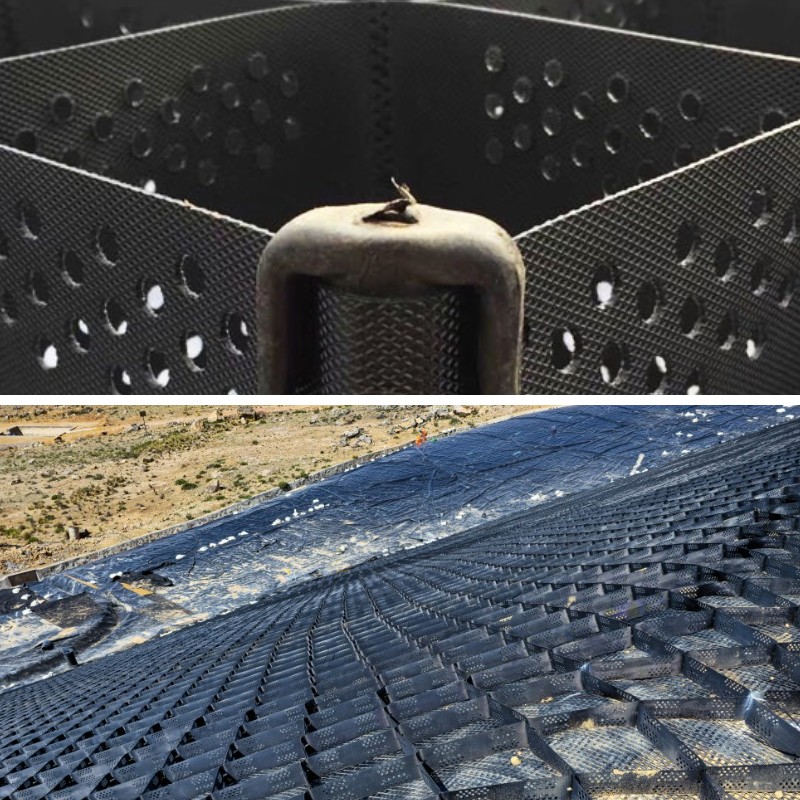

When planning a construction, landscaping, or erosion manipulate project, choosing the proper geocell cloth is integral to warding off high-priced reworks or venture failures. Two of the most frequent geocell substances on the market are Polypropylene (PP) and High-Density Polyethylene (HDPE). While each serve the core motive of stabilizing soil and reinforcing surfaces, their performance, durability, and fee differ significantly. In this guide, we’ll smash down the key variations between PP and geocell hdpe to assist you make an knowledgeable choice—with insights into geocell fee and real-world use cases.

1. Durability: Which Geocell Material Stands the Test of Time?

Durability is non-negotiable for geocells, as they frequently face harsh prerequisites like UV radiation, chemical exposure, and heavy loads. Here’s how PP and geocell hdpe compare:

PP Geocells: Moderate Durability for Short-to-Medium-Term Use

Polypropylene geocells are light-weight and provide respectable tensile strength, however they have boundaries in long-term resilience.

UV Resistance: PP is inclined to degradation underneath extended sunlight. Without extra UV stabilizers, PP geocells might also come to be brittle and crack inside 2–5 years of out of doors use. Even with stabilizers, their provider lifestyles hardly ever exceeds 10 years.

Chemical Resistance: They withstand slight acids and alkalis however can be broken with the aid of robust solvents (e.g., oil-based products), making them much less perfect for industrial or contaminated sites.

Load-Bearing Capacity: PP geocells manage mild to reasonable hundreds (e.g., pedestrian paths, small driveways) however may additionally deform below heavy visitors (e.g., trucks, building equipment).

HDPE Geocells: Superior Durability for Long-Term Projects

Geocell hdpe is engineered for toughness, making it the pinnacle desire for tasks requiring long-term performance.

UV Resistance: HDPE inherently resists UV damage. With superior UV stabilizers, HDPE geocells can final 15–25 years outdoors—perfect for everlasting constructions like highways or slope protection.

Chemical Resistance: HDPE stands up to harsh chemicals, together with oils, solvents, and industrial waste, making it appropriate for landfills, industrial yards, and coastal initiatives (resistant to saltwater corrosion).

Load-Bearing Capacity: Its excessive tensile electricity and stress permit HDPE geocells to assist heavy loads, such as freight trucks, railway tracks, and airport aprons, barring deformation.

Key Takeaway: For non permanent or low-load projects, PP geocells may additionally suffice. But for permanent, high-stress applications, geocell hdpe is the greater dependable geocell material.

2. Application Scenarios: Matching the Geocell Material to Your Project

The proper geocell fabric depends on your project’s environment, load requirements, and lifespan. Let’s map PP and geocell hdpe to frequent use cases:

PP Geocells: Best for Temporary or Light-Duty Projects

PP’s affordability (we’ll cowl geocell rate later) and average overall performance make it perfect for non-permanent or low-stress applications:

Temporary Parking Lots: Construction websites or match venues frequently use PP geocells to create brief parking—they’re handy to installation and remove, and their 2–5 12 months lifespan suits the project’s duration.

Residential Landscaping: Small backyard paths, outside patios, or light-weight preserving partitions (under three ft tall) advantage from PP’s flexibility and low cost.

Short-Term Erosion Control: Temporary slopes (e.g., at some point of street construction) can use PP geocells to forestall soil runoff till everlasting stabilization is in place.

HDPE Geocells: Ideal for Permanent, High-Stress Projects

Geocell hdpe shines in tasks that demand toughness and strength:

Highway & Railway Construction: HDPE geocells stabilize street bases and railway embankments, decreasing contract beneath heavy site visitors and extending the infrastructure’s lifespan through 10–15 years.

Slope Protection: Steep slopes (e.g., hillsides, coastal cliffs) remember on HDPE’s UV resistance and chemical balance to forestall erosion for decades. It’s additionally used in mine reclamation initiatives to impenetrable unfastened soil.

Landfills & Industrial Sites: HDPE’s resistance to chemical compounds and waste makes it the go-to geocell cloth for lining landfills or reinforcing industrial storage yards, the place sturdiness is quintessential for environmental safety.

Permanent Parking Lots: Commercial parking a lot (e.g., purchasing malls, workplace buildings) use HDPE geocells to manage day by day auto and truck site visitors except cracking or sinking.

Key Takeaway: Define your project’s lifespan and load first—PP for temporary/light use, geocell hdpe for permanent/heavy-duty needs.

3. Installation & Maintenance: Ease of Use vs. Long-Term Upkeep

Installing and keeping geocells impacts challenge timelines and costs. Here’s how PP and geocell hdpe differ:

PP Geocells: Faster Installation, Higher Maintenance

Installation: PP geocells are light-weight (typically 10–15% lighter than HDPE) and extra flexible, making them simpler to unroll and form round uneven terrain (e.g., sloped gardens). They require fewer equipment and can be mounted with the aid of a small crew in 1–2 days for residential projects.

Maintenance: PP’s decrease sturdiness capability greater widespread checks. For example, a PP geocell driveway can also want patching each and every 2–3 years due to UV injury or minor deformation. In areas with heavy rain, PP can additionally shift if no longer exact anchored, requiring repositioning.

HDPE Geocells: Slightly More Complex Installation, Minimal Maintenance

Installation: Geocell hdpe is stiffer and heavier, so it can also want greater labor to unroll—especially for giant initiatives like highways. It additionally requires unique leveling of the base soil to make sure acceptable load distribution. However, as soon as installed, it stays in place, lowering the want for adjustments.

Maintenance: HDPE’s lengthy lifespan and resistance to harm imply minimal upkeep. A toll road stabilized with geocell hdpe may additionally solely want annual inspections, no longer essential repairs, for 15+ years. Even in coastal areas, saltwater doesn’t corrode HDPE, getting rid of preservation prices associated to rust or degradation.

Key Takeaway: PP saves time on set up however charges greater in long-term maintenance. Geocell hdpe requires extra upfront effort however cuts down on future expenses—a trade-off well worth thinking about for everlasting projects.

4. Geocell Price: Initial Cost vs. Long-Term Value

Geocell charge is a pinnacle challenge for most buyers, however it’s necessary to seem to be past upfront charges and reflect onconsideration on whole cost over the project’s lifespan.

PP Geocells: Lower Initial Price, Higher Total Cost

Upfront Cost: PP geocells are typically 20–30% more cost effective than geocell hdpe. As of 2024, PP geocells value $1.20–$2.00 per rectangular foot, relying on thickness and UV stabilizer additives. For a 500-square-foot residential patio, this interprets to $600–$1,000 in fabric costs.

Long-Term Cost: PP’s shorter lifespan capacity you’ll want to change it each and every 5–10 years. For example, a PP parking lot costing $5,000 upfront can also want a $4,000 alternative after 7 years—total value of $9,000 over 14 years.

HDPE Geocells: Higher Initial Price, Lower Total Value

Upfront Cost: Geocell hdpe has a greater preliminary price, ranging from $1.80–$3.00 per rectangular foot. For the equal 500-square-foot patio, fabric expenses would be $900–$1,500—50% greater than PP upfront.

Long-Term Value: HDPE’s 15–25 12 months lifespan skill no alternative for decades. The equal parking lot the usage of geocell hdpe would value $7,500 upfront however $0 in substitute prices over 14 years—total value of $7,500, which is 17% more cost-effective than PP over the identical period.

Key Takeaway: If your assignment lasts 5 years or less, PP’s decrease geocell fee makes sense. For tasks longer than 5 years, geocell hdpe gives better fee by means of averting alternative costs.

Final Guide: How to Choose Between PP and HDPE Geocells

Follow these three steps to choose the proper geocell material:

1. Define Your Project’s Lifespan: <5 years = PP; >5 years = geocell hdpe.

2. Assess Load & Environment: Light loads/temporary use = PP; heavy loads/harsh stipulations (UV, chemicals) = geocell hdpe.

3. Calculate Total Cost: Compare upfront geocell fee + maintenance/replacement costs. HDPE wins for long-term savings.

Whether you’re constructing a outside course or a highway, deciding on between PP and geocell hdpe comes down to balancing performance, durability, and cost. By focusing on your project’s special needs, you’ll pick out a geocell that promises reliability and cost for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province