Geotextile Cloth vs. Traditional Fabrics: Key Differences in Performance

In construction, agriculture, and environmental projects, the preference of material can make or smash outcomes. Geotextile material (often referred to as geo fabric) and usual fabric like cotton, nylon, or polyester textiles serve wonderful purposes, however their overall performance features set them worlds apart. This information breaks down how these substances range in durability, functionality, and application—with a focal point on why geotextile solutions, in particular non woven geo fabric, outperform typical selections in heavy-duty scenarios.

What Are Geotextile Cloth and Traditional Fabrics?

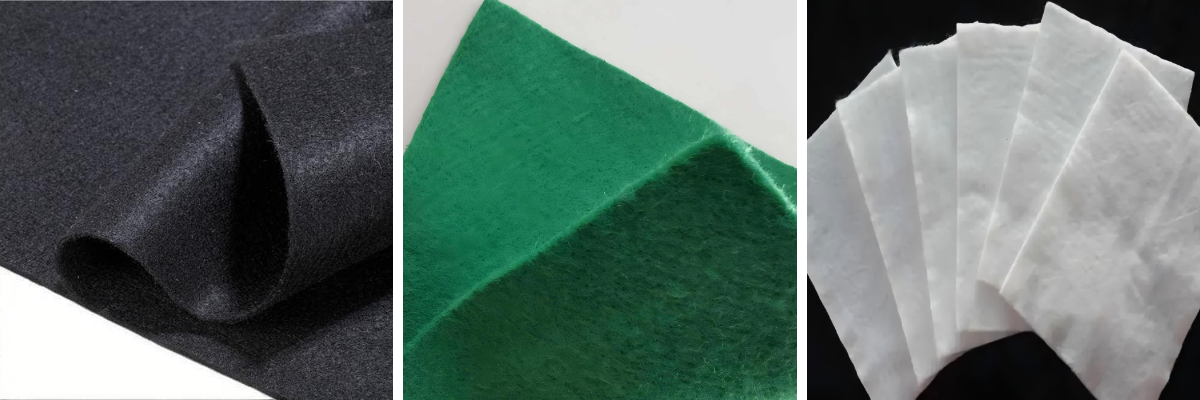

Geotextile material is a artificial engineered cloth designed for civil and environmental applications. Made from polypropylene, polyester, or polyethylene, it’s crafted to stand up to harsh conditions, inclusive of UV exposure, chemicals, and heavy loads. Geo cloth comes in woven, non woven, or knitted forms, every tailor-made to particular duties like drainage, separation, or reinforcement.

Traditional fabrics, by means of contrast, are particularly designed for clothing, upholstery, or mild industrial use. They’re regularly made from herbal fibers (cotton, wool) or artificial blends (nylon, polyester) however lack the structural engineering of geotextiles. Their focal point is on softness, breathability, or aesthetics—not sturdiness in outside or high-stress environments.

Durability: Geotextile Cloth Stands Up to the Elements

Resistance to Degradation

Geotextile material is constructed to last. UV-stabilized formulation stop breakdown from sunlight, a fundamental function for outside initiatives like street building or erosion control. Non woven geo fabric, for example, retains 80% of its power after 5+ years of exposure, whilst regular cotton fabrics degrade in 6–12 months underneath the equal conditions.

Traditional fabrics, even artificial ones like nylon, lack this stabilization. They fray, weaken, or rot when uncovered to moisture, chemicals, or severe temperatures—making them unsuitable for long-term out of doors use.

Tensile Strength

Geo material excels in tensile strength, the capacity to face up to stretching or tearing underneath pressure. Woven geotextile material can cope with 20–30 kN/m of force, best for reinforcing maintaining partitions or steep slopes. Non woven geo fabric, although greater flexible, nevertheless gives 10–15 kN/m, surpassing standard fabric like nylon (typically 5–8 kN/m).

Traditional fabric prioritize elasticity for comfort, no longer load-bearing. A cotton canvas, for instance, tears without difficulty beneath heavy soil or water pressure—rendering it useless in drainage or separation tasks.

Functional Performance: Geotextile Cloth Delivers Targeted Results

Permeability and Filtration

Geotextile material balances permeability and filtration, a key benefit over ordinary fabrics. Non woven geo fabric, with its porous structure, lets in water to drift via whilst trapping soil particles—preventing erosion in drainage systems. Woven geotextiles, with tighter weaves, manipulate water drift in functions like canal liners.

Traditional fabric fail here: cotton absorbs water and clogs, whilst nylon’s dense weave blocks drainage entirely. Neither can filter excellent sediments besides compromising flow, a dealbreaker for tasks like septic structures or agricultural drainage.

Soil Separation and Reinforcement

Geo fabric’s principal position is to separate materials—like maintaining gravel and soil from mixing in street bases. Its engineered shape continues integrity even underneath heavy compaction, making sure long-term stability. Traditional fabrics, too skinny and weak, tear or stretch, permitting fabric mixing that leads to potholes or structural failure.

In reinforcement, geotextile material distributes weight throughout massive areas, decreasing soil settlement. Roadways constructed with geo material require 30% much less gravel than these the use of ordinary fabrics, reducing fees and enhancing longevity.

Application-Specific Performance: Where Geotextiles Shine

Construction and Infrastructure

Geotextile fabric is crucial in road, bridge, and dam projects. Non woven geo material strains trenches to forestall pipe harm from soil movement, whilst woven sorts strengthen embankments. Traditional fabric can’t suit this: the usage of cotton in street beds leads to fast erosion and highly-priced repairs

Agriculture and Environmental Projects

In farming, geo material controls weeds besides chemical substances and improves water distribution in irrigation systems. Non woven geo fabric, positioned beneath mulch, approves moisture to attain roots whilst blocking off sunlight—outperforming plastic sheeting (a standard alternative) which cracks and desires generic replacement.

For erosion control, geotextiles stabilize slopes and riverbanks. Their capability to keep soil whilst draining extra water surpasses straw mats or burlap (traditional options), which wash away in heavy rains.

Cost-Effectiveness: Geotextile Cloth Saves Long-Term

While geotextile material has a greater upfront fee than standard fabrics, its toughness makes it more cost-effective over time. A non woven geo material set up in a landfill liner lasts 20+ years, whilst a nylon material would want alternative each and every 2–3 years—doubling whole costs.

Traditional fabric can also appear budget-friendly, however their customary alternative and assignment screw ups (like eroded slopes or clogged drains) make them a highly-priced preference for heavy-duty applications.

Conclusion: Geotextile Cloth Outperforms in Heavy-Duty Scenarios

Geotextile cloth, particularly non woven geo fabric, outmatches common fabric in durability, functionality, and cost-effectiveness. Designed for engineering challenges, it resists degradation, filters efficiently, and reinforces structures—tasks past the scope of fabric made for garb or mild use.

For tasks requiring long-term reliability—whether construction, agriculture, or environmental restoration—geo cloth is the clear choice. Its overall performance traits, tailor-made to out of doors and high-stress environments, make certain success the place ordinary fabric would fail. When sturdiness and consequences matter, geotextile material delivers.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province