Geomembrane Repair & Maintenance: Extending Lifespan & Performance

The Significance of Geomembranes

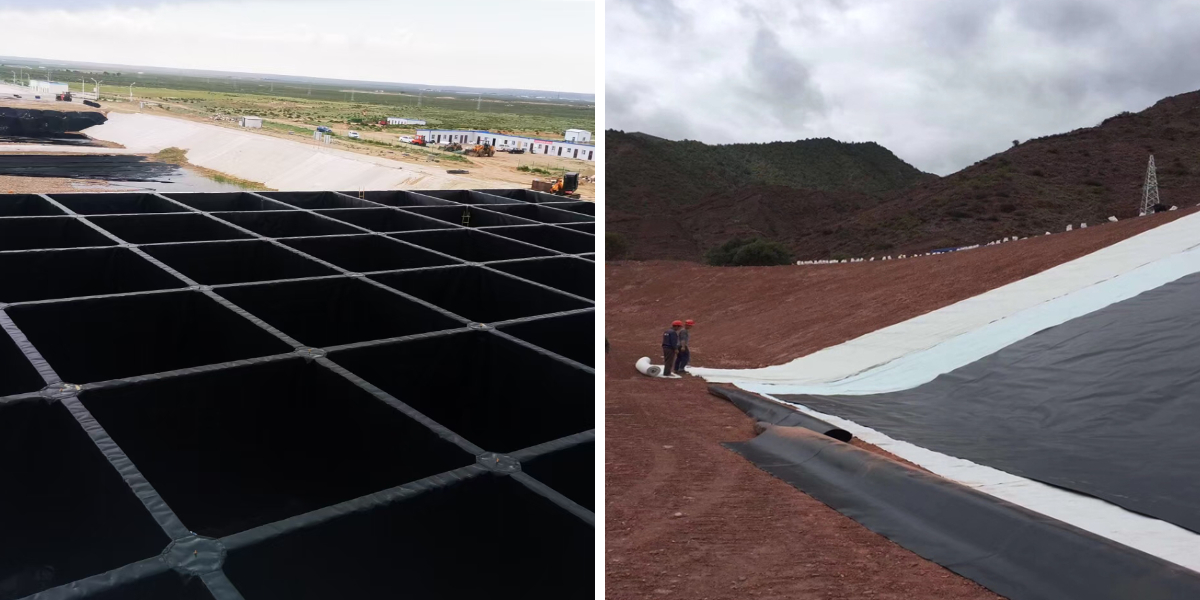

Geomembranes play a critical function in a large vary of industries, imparting crucial features such as waterproofing, isolation, and protection. Among them, HDPE geomembrane, HDPE pond liner, and easy geomembrane are mainly famous due to their exquisite overall performance and versatility.

HDPE geomembrane, made from excessive - density polyethylene, is famend for its excessive strength, low permeability, and incredible chemical resistance. It can efficiently stop the leakage of drinks and gases, making it an perfect preference for purposes in landfills, wastewater therapy plants, and industrial storage facilities. For example, in a landfill, an HDPE geomembrane serves as a barrier to comprise leachate, stopping it from contaminating the surrounding soil and groundwater.

HDPE pond liner, a kind of HDPE geomembrane in particular designed for pond applications, helps to continue water in ponds, lakes, and aquaculture facilities. It now not solely prevents water seepage however additionally gives a steady surroundings for aquatic life. In aquaculture, an HDPE pond liner can hold the water pleasant and temperature, advertising the healthful boom of fish and shrimp.

Smooth geomembrane, with its clean surface, gives benefits such as convenient set up and low friction. It is regularly used in initiatives the place a clean interface is required, such as in the lining of canals, tunnels, and some industrial pipelines.

These geomembranes are fundamental to the success of engineering projects. They shield the environment, make sure the efficient use of resources, and decorate the protection and sturdiness of structures. However, like any different engineering material, they are challenge to put on and tear over time, which is why suited restore and upkeep are essential.

Purpose of the Article

The motive of this article is to grant you with complete expertise about geomembrane restore and maintenance. By appreciation these aspects, you can successfully lengthen the lifespan of your geomembrane products, whether or not they are HDPE geomembranes, HDPE pond liners, or clean geomembranes. Moreover, appropriate upkeep can beautify their performance, making sure that they proceed to feature optimally in quite a number applications. Whether you are a assignment manager, an engineer, or a facility operator, the statistics in this article will assist you make knowledgeable selections and take fabulous moves to care for your geomembranes.

Types of Geomembranes: An Overview

Understanding the exclusive sorts of geomembranes is essential to their appropriate use, repair, and maintenance. Each type, such as HDPE geomembrane, HDPE pond liner, and clean geomembrane, has its personal special traits and applications.

HDPE Geomembrane

HDPE (High - Density Polyethylene) geomembrane is one of the most broadly used geomembranes in the industry. It is characterised via its excessive chemical stability. HDPE geomembranes can withstand the corrosion of a vast vary of chemicals, which include acids, alkalis, and salts. This makes them appropriate for use in industrial waste storage facilities, the place they forestall the leakage of dangerous chemical substances into the environment.

In phrases of bodily properties, HDPE geomembranes have exceptional puncture resistance. Their excessive tensile power permits them to face up to exterior forces except being without difficulty punctured, even in difficult terrains or areas with viable sharp objects. For example, in landfill projects, HDPE geomembranes are laid at the backside and facets of the landfill to stop the leachate from contaminating the soil and groundwater. The puncture - resistant property ensures that the geomembrane can preserve its integrity over time, regardless of the weight and motion of the waste materials.

HDPE geomembranes are additionally exceptionally impermeable. With a very low water vapor transmission rate, they can efficaciously block the passage of beverages and gases. This makes them vital in water - associated projects, such as dams, canals, and reservoirs. In a dam project, an HDPE geomembrane can be used as an impermeable layer to stop water seepage, making sure the steadiness and protection of the dam structure.

HDPE Pond Liner

An HDPE pond liner is a specialised kind of HDPE geomembrane designed specially for pond applications. It serves as a necessary element in aquaculture and panorama pond projects. In aquaculture, an HDPE pond liner creates a secure and easy surroundings for aquatic organisms. It prevents water from seeping into the ground, which helps to keep the water degree and high-quality in the pond. For instance, in a shrimp farming pond, the HDPE pond liner ensures that the salinity and temperature of the water are consistent, merchandising the healthful increase of shrimp.

In panorama ponds, HDPE pond liners now not solely forestall water loss however additionally decorate the aesthetic attraction of the pond. They can be without difficulty set up in a variety of shapes and sizes, permitting for innovative and special pond designs. Moreover, HDPE pond liners are resistant to daylight and weathering, which capability they can hold their overall performance even when uncovered to the factors for lengthy periods. This is essential for out of doors panorama ponds, as it reduces the want for familiar replacements and maintenance.

Smooth Geomembrane

Smooth geomembranes, as the title implies, have a clean surface. One of the major benefits of this easy floor is its low friction coefficient. This makes the set up technique easier, as the geomembrane can be without difficulty unrolled and located on the site. During the building of a massive - scale reservoir project, the low - friction easy geomembrane can be rapidly laid out, saving each time and labor costs.

The clean floor of the geomembrane additionally helps to forestall the accumulation of dirt, debris, and organic matter. In a wastewater therapy plant, the place the geomembrane is used to line the remedy tanks, the easy floor ensures that sludge and different impurities do no longer stick to the membrane, making it simpler to easy and maintain. This, in turn, helps to enhance the effectivity of the wastewater therapy process. Smooth geomembranes are regularly used in initiatives the place a easy interface is required, such as in the lining of tunnels and some industrial pipelines. Their easy floor reduces the resistance to fluid flow, making sure the easy transportation of fluids.

Common Damage and Degradation Issues

Physical Damage

Physical injury to geomembranes is a frequent hassle that can manifest at some point of each the building and the day by day use of a number projects.

During construction, heavy equipment is regularly used, which can purpose mechanical injury to HDPE geomembranes, HDPE pond liners, and easy geomembranes. For example, bulldozers and excavators may additionally by chance run over the geomembrane, developing cuts, punctures, or tears. Even the motion of development people and the transportation of constructing substances can make a contribution to bodily damage. If sharp - edged substances are dragged throughout a clean geomembrane at some stage in construction, it can without difficulty be punctured, compromising its integrity.

In each day use, the presence of sharp objects in the surroundings can additionally pose a threat. In a landfill, for instance, waste substances with sharp edges such as damaged glass or steel portions can pierce an HDPE geomembrane, leading to leaks. In an aquaculture pond lined with an HDPE pond liner, the motion of fish or the use of some equipment in the pond might also by accident reason tears in the liner.

Chemical Degradation

Chemical degradation happens when geomembranes are uncovered to more than a few chemical substances. Although HDPE geomembranes are acknowledged for their notable chemical resistance, they are now not immune to the consequences of all chemicals.

In industrial settings, for example, if an HDPE geomembrane is used to line a storage tank for fantastically reactive chemicals, over time, the chemical substances may also step by step erode the geomembrane. Strong acids, alkalis, and some natural solvents can react with the HDPE material, main to a trade in its molecular structure. This can purpose the geomembrane to grow to be brittle, lose its tensile strength, and in the end fail to function its supposed function. In a chemical plant, if a leaky pipe lets in a focused acid answer to come into contact with an HDPE geomembrane used for floor protection, the acid can begin to degrade the membrane.

In agricultural applications, fertilizers, pesticides, and herbicides can additionally have an influence on the performance of HDPE pond liners used in irrigation ponds. These chemicals, specially when current in excessive concentrations or underneath positive temperature and pH conditions, can slowly degrade the liner, decreasing its lifespan.

UV Degradation

Ultraviolet (UV) radiation from the solar is a sizable issue in the degradation of geomembranes, particularly these that are uncovered to daylight for prolonged periods.

HDPE geomembranes are generally formulated with UV - resistant components to help guard them from the damaging consequences of UV rays. However, over time, these components can turn out to be depleted, and the geomembrane's resistance to UV degradation will decrease. In outside functions such as a landfill cowl made of an HDPE geomembrane or a giant - scale water storage pond lined with an HDPE pond liner, non-stop publicity to daylight can reason the geomembrane to turn out to be discolored, brittle, and cracked.

Smooth geomembranes, when used in open - air tasks like the lining of canals, are additionally prone to UV degradation. The UV rays ruin down the polymer chains in the geomembrane material, weakening its bodily properties. This can lead to a discount in the membrane's tensile electricity and elongation capabilities, making it extra inclined to punctures and tears. To mitigate UV degradation, it is integral to grant perfect protection, such as overlaying the geomembrane with a layer of soil, geotextile, or different protecting substances as quickly as feasible after installation.

Inspection: The First Step

Regular and thorough inspection is the cornerstone of positive geomembrane restore and maintenance. By detecting troubles early, you can stop minor troubles from escalating into main failures, saving each time and cash in the lengthy run.

Regular Visual Checks

Regular visible assessments are the easiest but one of the most necessary inspection methods. For HDPE geomembranes, HDPE pond liners, and clean geomembranes, visible inspections ought to be carried out at least once a month in ordinary conditions. However, in areas with excessive - stress functions or severe environmental conditions, such as landfills with non-stop waste disposal or aquaculture ponds with prevalent water circulation, inspections may also want to be extra frequent, possibly weekly.

During visible inspections, pay shut interest to the floor of the geomembrane. Look for any symptoms of bodily damage, such as cuts, punctures, and tears. Even small punctures, which may additionally be as tiny as a pinhole, can lead to huge leakage over time, mainly in functions involving beverages beneath pressure. Check for wrinkles or folds, as these can point out unsuitable set up or stress factors on the geomembrane. In the case of an HDPE pond liner, wrinkles may also reason uneven water strain distribution, probably main to damage. Also, be on the lookout for any signs and symptoms of discoloration, which may want to be an early indication of chemical or UV degradation. For example, a yellowing or fading of an HDPE geomembrane used in an out of doors landfill cowl may additionally endorse UV damage.

Non - Destructive Testing Methods

In addition to visible checks, non - negative checking out (NDT) strategies play a fundamental position in detecting hidden defects in geomembranes. One of the most normally used NDT techniques is the electrical method.

The electrical method, such as the electrical leak vicinity (ELL) technique, works based totally on the precept of electrical conductivity. A voltage is utilized throughout the geomembrane, and if there is a defect, such as a gap or a crack, an electrical modern will glide thru the defect, developing a detectable signal. In a landfill with an HDPE geomembrane liner, this technique can precisely discover even small leaks that are no longer seen to the bare eye. By mapping the electrical signals, the actual function and dimension of the defect can be determined. This approves for focused restore efforts, minimizing the want to restore giant areas of the geomembrane.

Another non - unfavorable trying out technique is the ultrasonic checking out method. Ultrasonic waves are despatched thru the geomembrane, and the mirrored waves are analyzed. Any interior defects or delaminations in the HDPE geomembrane or easy geomembrane will reason adjustments in the ultrasonic wave patterns, which can be detected and analyzed to determine the integrity of the geomembrane. These non - negative trying out strategies are mainly beneficial for detecting defects that are no longer without difficulty seen at some point of visible inspections, making sure the lengthy - time period overall performance of the geomembrane.

Repair Techniques

Once damage to HDPE geomembranes, HDPE pond liners, or easy geomembranes has been detected thru inspection, excellent restore methods ought to be employed straight away to forestall similarly deterioration. The desire of restore approach relies upon on the kind and extent of the damage.

Small Holes and Tears

For small holes and tears, which are usually much less than 5 - 10 centimeters in size or diameter, a patch - and - glue approach is often used.

First, the place round the broken web page wishes to be entirely cleaned. Remove any dirt, debris, or moisture from the floor of the geomembrane. This can be carried out the use of a clean, dry material and, if necessary, a slight solvent. For an HDPE pond liner with a small puncture, cautiously wipe the region round the gap to make sure a smooth floor for the patch to adhere to.

Next, choose a appropriate patch material. The patch need to be made of the identical or a like minded fabric as the geomembrane. For example, if it is an HDPE geomembrane that is damaged, an HDPE patch is ideal. The dimension of the patch have to be massive sufficient to cowl the broken place with a margin of at least 10 - 15 centimeters on all sides.

Apply a excessive - quality, geomembrane - like minded adhesive to each the lower back of the patch and the floor of the geomembrane round the damage. There are unique adhesives designed for bonding HDPE materials. Spread the adhesive evenly the usage of a brush or a roller, making certain to cowl the complete bonding area.

Carefully area the patch over the broken area, beginning from one facet and steadily smoothing it down to keep away from trapping air bubbles. Press firmly on the patch to make sure top adhesion. Use a curler or a hand - held press device to observe even stress throughout the patch, improving the bond between the patch and the geomembrane.

Larger Damages

When dealing with large damages, such as tears longer than 10 centimeters or massive punctured areas, really patching can also no longer be sufficient. In these cases, the broken area of the geomembrane need to be reduce out and replaced.

Mark the boundaries of the broken region clearly. Use a sharp utility knife or a reducing device appropriate for the geomembrane fabric to cautiously reduce out the broken piece of the HDPE geomembrane, HDPE pond liner, or easy geomembrane. Make positive the reduce edges are straight and clean.

Prepare a substitute piece of the geomembrane. The substitute piece have to be of the equal material, thickness, and fine as the authentic geomembrane. Its dimension need to be such that it can be top joined to the final intact geomembrane with a adequate overlap.

The becoming a member of of the alternative piece to the authentic geomembrane is typically accomplished thru warmness welding or chemical splicing. Heat welding is a frequent technique for HDPE geomembranes. A warmness - welding computer is used to soften the edges of the substitute piece and the unique geomembrane, fusing them together. The welding temperature, speed, and stress want to be cautiously managed in accordance to the manufacturer's instructions. For example, in a landfill challenge the place an HDPE geomembrane has a massive tear, the alternative piece is warmth - welded to the current membrane. The operator adjusts the warmness - welding computing device settings based totally on the thickness of the HDPE geomembrane to make certain a sturdy and leak - free bond.

Chemical splicing entails the usage of a chemical agent to bond the two portions of geomembrane together. This approach requires particular software of the chemical agent and cautious dealing with to make sure the protection of the employees and the fantastic of the splice. After the repair, it is fundamental to behavior a first-class check, such as a visible inspection and a stress check if applicable, to make certain that the repaired region is functioning top and there are no leaks.

Maintenance Practices

Cleaning and Debris Removal

Maintaining a easy floor is of utmost significance for geomembranes, which include HDPE geomembranes, HDPE pond liners, and clean geomembranes. Regular cleansing helps to stop viable harm and make certain the lengthy - time period performance of the geomembrane.

Debris such as rocks, branches, and sharp - edged objects can reason punctures and tears in the geomembrane. For example, in a landfill, if massive rocks are left on the floor of an HDPE geomembrane, they can create strain factors that can also finally lead to the formation of holes or cracks over time due to the weight of the waste and herbal settling processes. In an aquaculture pond with an HDPE pond liner, floating particles like sticks can puncture the liner when moved by means of water currents or at some point of pond renovation activities.

Therefore, it is crucial to frequently do away with particles from the floor of the geomembrane. This can be performed the usage of easy equipment such as brooms, rakes, or vacuum cleaners, relying on the nature of the particles and the place of the geomembrane. By preserving the floor clean, the chance of bodily harm to the geomembrane is substantially reduced, which in flip helps to hold its integrity and performance.

Protection from External Factors

Geomembranes are frequently uncovered to a number of exterior elements that can reason degradation and damage. Taking gorgeous defensive measures is critical to prolong their lifespan.

One of the foremost threats to geomembranes is ultraviolet (UV) radiation from the sun. As cited earlier, UV rays can smash down the polymer shape of the geomembrane, main to brittleness, cracking, and loss of mechanical properties. To shield towards UV degradation, a layer of soil, geotextile, or different UV - resistant cowl substances can be positioned over the geomembrane. In a massive - scale water storage assignment the usage of an HDPE geomembrane, protecting the membrane with a layer of soil no longer solely gives safety from UV rays however additionally provides mechanical protection.

Mechanical harm from building activities, gear movement, or even animal things to do can additionally be a problem. In areas the place there is building close to a geomembrane - lined structure, such as a wastewater remedy plant with a clean geomembrane lining, limitations can be set up to stop heavy equipment from by chance negative the geomembrane. Additionally, in agricultural areas the place HDPE pond liners are used, fencing can be hooked up round the ponds to maintain out cattle that may also trample on the liner.

Periodic Re - evaluation

The circumstance of geomembranes can trade over time due to quite a number factors, which includes environmental conditions, utilization patterns, and the herbal ageing process. Therefore, periodic re - contrast of the geomembrane's circumstance is essential.

Regular inspections and assessments must be carried out at constant intervals, such as yearly or bi - annually, relying on the significance and utilization of the geomembrane. During these evaluations, the bodily situation of the geomembrane, along with any symptoms of damage, degradation, or adjustments in performance, have to be cautiously assessed. If an HDPE geomembrane used in a landfill has shown symptoms of elevated brittleness all through a preceding inspection, a extra in - depth evaluation might also be wanted in the course of the subsequent re - comparison to decide the extent of the trouble and whether or not any in addition defensive or restore measures are required.

Based on the outcomes of the re - evaluation, the protection method can be adjusted accordingly. If minor damages are detected, immediately repairs can be scheduled. If the ordinary circumstance of the geomembrane is deteriorating greater unexpectedly than expected, extra defensive measures may additionally be implemented, or the substitute time table may additionally be accelerated. This proactive method to preservation helps to make certain that the geomembrane continues to characteristic correctly during its meant lifespan.

Conclusion

Recap of Key Points

Throughout this article, we have delved deep into the integral components of geomembrane restore and maintenance. We started out via perception the value of exclusive kinds of geomembranes, such as HDPE geomembrane, HDPE pond liner, and clean geomembrane, and their special purposes throughout a variety of industries.

Physical damage, chemical degradation, and UV degradation had been recognized as frequent threats to geomembranes. Physical damage, frequently triggered through building things to do or sharp objects, can lead to punctures and tears in HDPE geomembranes, HDPE pond liners, and clean geomembranes. Chemical degradation, ensuing from publicity to reactive chemicals, and UV degradation, due to lengthy - time period daylight exposure, can weaken the geomembrane's shape and minimize its performance.

Inspection, the first step in maintenance, includes everyday visible tests to spot floor - stage troubles like cuts, punctures, and discoloration. Non - negative trying out methods, such as electrical and ultrasonic testing, assist notice hidden defects. When it comes to repair, small holes and tears can be constant the usage of the patch - and - glue method, whilst large damages require slicing out the broken area and changing it via warmth welding or chemical splicing. Maintenance practices encompass cleansing and particles elimination to forestall bodily damage, safety from exterior elements like UV radiation and mechanical damage, and periodic re - assessment to regulate upkeep techniques primarily based on the geomembrane's altering condition.

Final Thoughts on Lifespan and Performance Extension

In conclusion, perfect restore and protection are of utmost significance for extending the lifespan and improving the overall performance of HDPE geomembranes, HDPE pond liners, and easy geomembranes. By investing time and assets in ordinary inspections, well timed repairs, and regular maintenance, you can keep away from high-priced replacements and make certain the persevered effectiveness of your geomembrane systems. Whether it is defending the surroundings in landfills, keeping water high-quality in aquaculture ponds, or making sure the clean waft of fluids in industrial pipelines, properly - maintained geomembranes play a critical role. We motivate you to put into effect the restore and renovation methods mentioned in this article to protect your geomembrane investments and obtain lengthy - time period success in your projects.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province