Geotextile Tube Maintenance: Best Practices to Extend Lifespan & Avoid Leaks

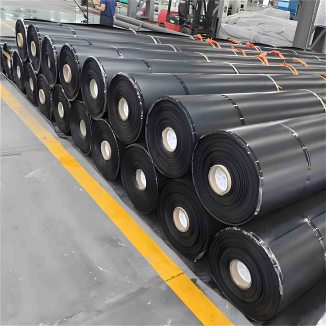

Geotextile tubes (or geotubes) are quintessential in civil, coastal, and environmental engineering—supporting shoreline protection, sediment control, and landfill capping. Their overall performance doesn’t quit with perfect geotube installation, though; steady protection is key to stopping leaks, keeping structural integrity, and extending their 10–20 yr provider life. Below are 4 core pleasant practices to hold geotextile tubes functional, with a focal point on aligning upkeep with preliminary geotube set up quality.

1. Regular Inspections: Proactive Care for Geotextile Tubes

Routine inspections are the first line of protection towards small troubles turning into expensive failures. Even a well-executed geotube set up can increase susceptible factors over time—from weathering to unintentional damage—so regular exams are essential.

Inspection frequency relies upon on the application: intention for quarterly tests for popular makes use of (like inland sediment ponds) and month-to-month tests for high-stress environments (such as coastal erosion control), plus extra inspections after excessive climate like storms or heavy rainfall. Focus on key areas that hyperlink returned to geotube installation: seams and joints (the most frequent leak points, as they depend on the watertight seals created all through installation), surface integrity (looking for tears or punctures from debris), and anchorage (ensuring the tube hasn’t shifted— a hazard of rushed geotube installation). For massive or hard-to-reach geotextile tubes, use drones for aerial overviews and handheld cameras to record small defects, making sure no problems go unnoticed.

2. Strategic Cleaning: Protect Geotextile Tubes From Buildup

Over time, geotextile tubes accumulate debris, sediment, algae, or industrial byproducts—all of which degrade the material and block its filtration capabilities. Cleaning is crucial for maintaining function, specially for geotextile tubes established in high-sediment or polluted areas (where geotube set up prioritizes durability).

Start by way of putting off unfastened particles with a soft-bristle broom or leaf blower, fending off sharp metallic equipment that may want to scratch the geotextile fabric. For caked-on sediment or algae, use a high-pressure washer with a fan nozzle (keep it at least 12 inches from the tube’s floor to keep away from adverse the weave). Never use bleach, solvents, or acidic cleaners—these smash down the geotextile’s polymer fibers and amplify leak risk. Instead, use a mild, biodegradable detergent for chronic growth. Time cleanings to forestall buildup from hardening: act after heavy rain (which washes sediment onto the tube) or seasonal activities like iciness ice melt.

3. Prompt Repairs: Stop Leaks Before They Worsen

Even with inspections and cleaning, geotextile tubes may also preserve damage—from impacts, animal activity, or climate wear. A small 1-inch tear can enlarge to a foot-wide leak in weeks (especially underneath strain from water or sediment), so instantaneous repairs are critical.

Begin by using assessing the damage: observe if it’s a tear, puncture, or seam separation, and measure its size. For damages large than 6 inches, seek advice from the group that dealt with the unique geotube installation—they apprehend the fabric’s specifications. Next, smooth the broken vicinity with slight cleaning soap and water, then dry it totally to take away unfastened threads. Use a patch made from the equal geotextile cloth (save leftovers from geotube set up for this purpose): self-adhesive patches work for small punctures, whilst two-part epoxy or heat-welding equipment are higher for large tears or seam issues. Center the patch so it extends at least three inches past the defect, press out air bubbles, and let it therapy 24–48 hours earlier than exposing the geotextile tube to pressure—this ensures repairs fit the satisfactory of the preliminary installation.

4. Environmental Protection: Shield Geotextile Tubes Long-Term

Geotextile tubes are constructed for harsh conditions, however extended publicity to environmental threats shortens their lifespan. Protecting them enhances the sturdiness designed into geotube installation, making sure a long time of performance.

Guard in opposition to ultraviolet (UV) radiation—sunlight breaks down polymer fibers, inflicting brittleness—by selecting UV-stabilized geotextiles all through geotube set up (critical for above-ground makes use of like landfill caps) and overlaying uncovered tubes with soil, gravel, or vegetation. For chemical publicity (common in wastewater treatment), choose chemical-resistant geotextiles at some stage in set up and display water/sediment fantastic to trap leaks early. Prevent organic increase (algae, barnacles) by using sticking to everyday cleansing and making use of non-toxic, biodegradable anti-fouling coatings (approved for environmental use) to the geotextile tube’s surface.

Conclusion: Maintenance + Geotube Installation = Longevity

A geotextile tube’s lifespan relies upon on two factors: the precision of its geotube set up and constant maintenance. By following these practices—regular inspections, strategic cleaning, immediate repairs, and environmental protection—you’ll keep away from expensive leaks, reduce alternative costs, and hold geotextile tubes dependable for years. Proactive care these days saves time and budgets tomorrow, no count number the project.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province