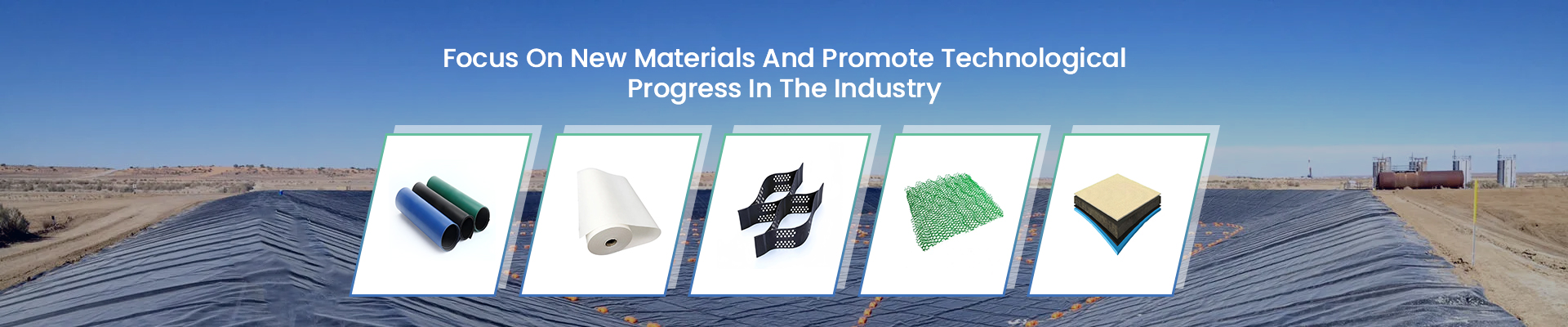

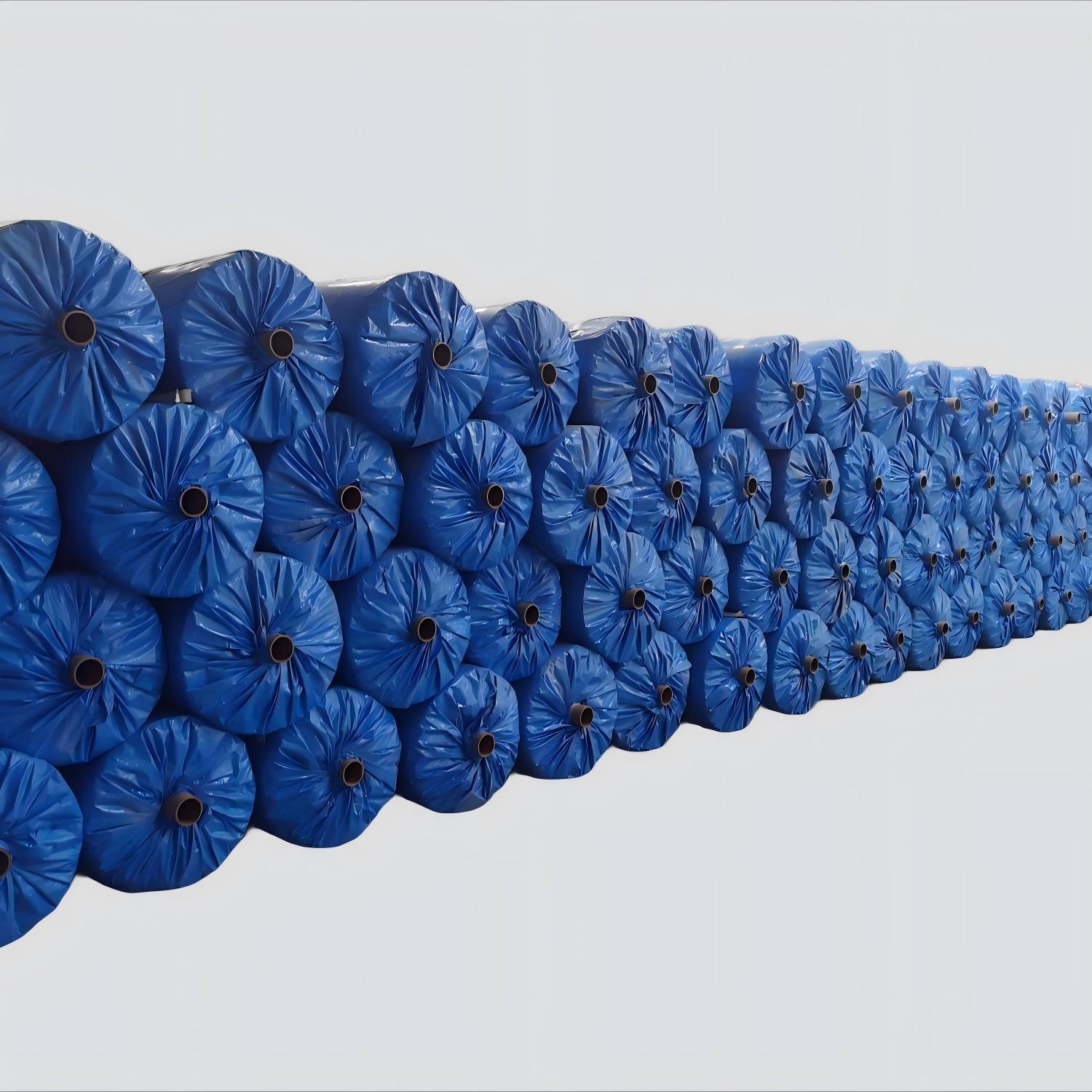

Waterproof Concrete Canvas

1.Rapid Installation:

Achieves 80% strength within 24 hours after laying, 10 times faster than traditional concrete.

2.No Formwork Required:

Conforms directly to complex surfaces (e.g., slopes, trenches).

3.Lightweight:

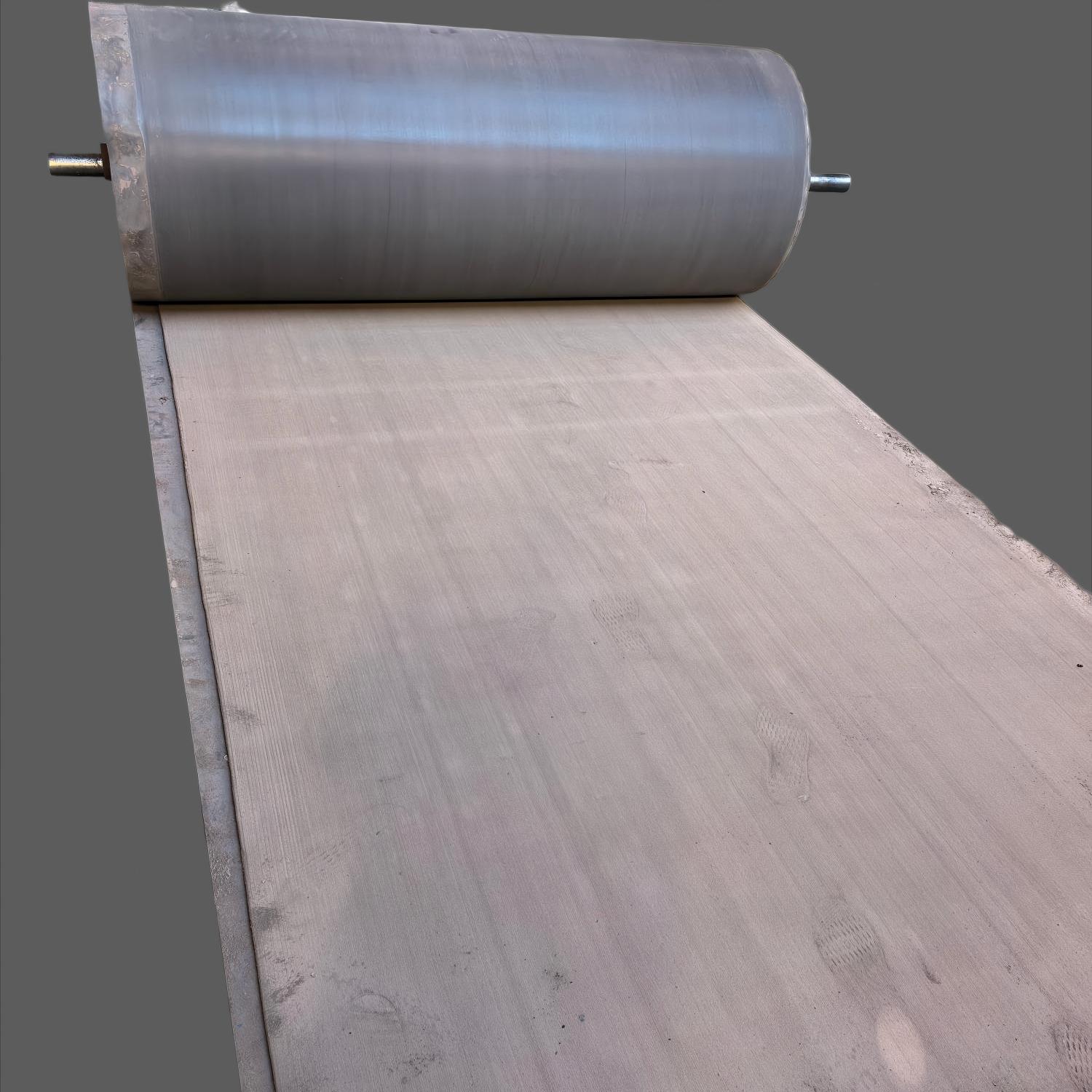

The CC13 variant weighs approximately 15 kg/m², reducing transportation costs.

4.Eco-Friendly:

Reduces material waste by ~95% and cuts carbon emissions by 50% compared to conventional concrete.

Product Introduction:

Waterproof Concrete Canvas are innovative composite material that combines a flexible fibrous matrix with a specially formulated dry-mix cement, creating a "fabric-like concrete." It hardens upon hydration to form a high-strength, waterproof, and fire-resistant concrete layer. By merging the flexibility of textiles with the durability of concrete, it significantly simplifies traditional concrete construction processes.

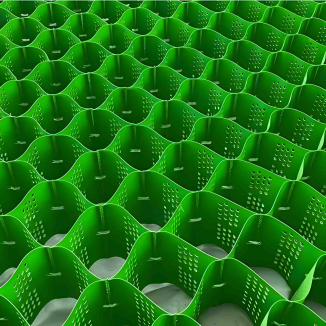

Structure and Composition

Outer Layer: Polyethylene (PE) or polyvinyl chloride (PVC) coating, providing waterproofing and UV resistance.

Middle Layer: A 3D fibrous matrix (typically polypropylene or fiberglass) for enhanced tensile strength.

Inner Layer: Dry-mix cement powder (containing Portland cement, fine aggregates, and additives) that hydrates upon water exposure to form concrete.

Product Parameters:

surveillance project | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test basis | remarks |

length (M) | 10--50 | / | |||

width (M) | 1--3 | / | |||

thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm | / | |||

Compressive strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T17671-2021 | |

Flexural strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

Flexural strength retention rate after freeze-thaw cycles (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | The freezing and thawing cycle from 50 to 200 times changed the indexes accordingly |

Water quality requirements for hydration | running water | Tap water, sea water | Tap water, seawater, sewage | / | |

Construction temperature conditions | · Construction above 0℃ | · Construction above-5℃ | · Construction above-5℃ | / | |

fire protecting performance | B1 | GB 8624-2012 | |||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||

Copper (total copper) (mg/L) | ≤100 | ||||

Zinc (total zinc) (mg/L) | ≤100 | ||||

Cadmium (total) (mg/L) | ≤1 | ||||

Lead (total lead) (mg/L) | ≤5 | ||||

Total chromium (mg/L) | ≤15 | ||||

Nickel (total nickel) | ≤5 | ||||

Arsenic (total) | ≤5 | ||||

Product Applications:

1.Hydraulic Engineering

It can be used for anti-seepage, lining, and reinforcement of rivers, scenic lakes, canals, etc., to prevent water erosion and seepage, and improve the stability and service life of hydraulic facilities.

2.Transportation Engineering

In the construction of highways, railways, bridges, subways, etc., it can be used for laying temporary roads, reinforcing roadbeds, repairing pavements, bridge reinforcement, and tunnel lining, etc., to bear the loads of vehicles and pedestrians.

3.Agricultural Field

It is suitable for anti-seepage of aquaculture ponds, hardening of livestock breeding site grounds, construction and maintenance of agricultural irrigation channels, etc., to improve the quality and durability of agricultural production facilities.

4.Emergency Projects

Such as the construction of temporary tents, reinforcement of dams during flood control and emergency rescue, soft foundation treatment, etc., which can be quickly constructed to provide emergency protection and support.

5.Environmental Engineering

It can be used for windbreak and sand fixation, laid in desert edges or areas with heavy wind and sand to fix sand; it can also be used for anti-seepage treatment of landfills and sewage treatment plants to prevent pollutant leakage.

6.Marine Engineering

Such as protection of submarine optical cables, protection of bridge piers, reclamation slope protection, etc., to resist the erosion and scouring of seawater.

Concrete Canvas revolutionizes concrete applications through material science innovation, making it particularly suitable for disaster relief, remote areas, and complex terrain engineering. It represents a disruptive technology in the field of civil engineering.