Erosion Control Concrete Canvas

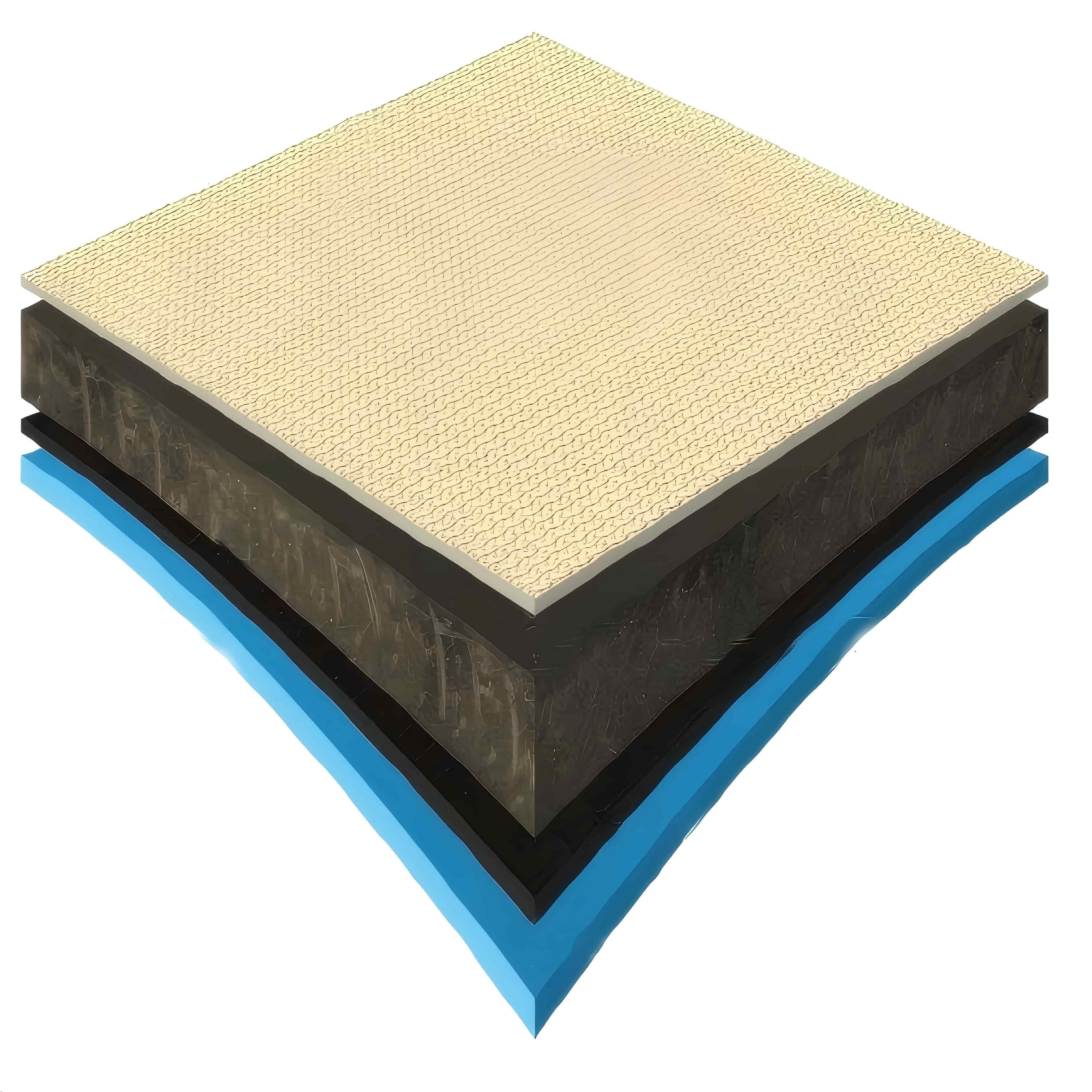

Composite cement blanket is an innovative composite material that combines the flexibility of textiles with the firmness of cement, and can be quickly laid and hardened into a durable concrete layer.

High construction efficiency: No professional equipment is required. It can be laid by a single person and is 10 times faster than traditional concrete. Fast forming, available in rolls or bulk, convenient for transportation, loading and unloading, and installation.

Environmental protection and energy conservation: Reduce material waste and lower carbon emissions by over 90% compared to traditional processes.

Strong flexibility: It can be cut to adapt to complex terrains and even used for vertical suspension.

Durability: Resistant to freeze-thaw cycles, corrosion, wear, erosion, seawater and sewage corrosion

The service life of UV aging resistance can reach 50 years.

The product advantages of Erosion Control Concrete Canvas are mainly reflected in its rapid construction, flexible adaptability, environmental protection and energy conservation, and multi-functionality, etc. Specifically, they can be summarized as the following core characteristics:

1. The construction efficiency is extremely high

- Ready to use upon laying: After spreading, water it and it will harden immediately. It reaches its usable strength within 24 hours, which is more than 10 times faster than traditional concrete construction (requiring 7 to 28 days of curing).

- No complex equipment required: It can be operated by a single person, eliminating the need for mixing, pouring, vibration and other steps. It is especially suitable for remote areas without electricity or mechanical support.

All-weather operation: Unaffected by adverse weather conditions such as rain, snow and low temperatures, it can quickly respond to emergency engineering needs (such as flood control and rescue).

2. Flexibility and adaptability

- Cropped and bendable: It can be cut into any shape to adapt to complex terrains such as slopes, ditches, and irregular structures, and can even be used for vertical suspension.

- ightweight transportation: The weight per square meter is only about 15-25 kilograms (with different thicknesses), and the roll form is convenient for vehicle or manual handling.

Seamless forming: After hardening, a continuous concrete layer is formed without seams, avoiding the risk of leakage (such as anti-seepage in water conservancy projects).

3. Environmental Protection and Sustainability

- Reduce material waste: Cut as needed, precisely control the amount of cement used, and avoid excessive pouring of traditional concrete and the generation of waste.

- Low carbon emissions: Carbon emissions during the production and usage process are reduced by over 90% compared to traditional concrete (no need for heavy machinery or long-distance transportation).

- High durability: Resistant to freeze-thaw cycles and corrosion, with a service life of up to 50 years, reducing later maintenance and resource consumption.

4. Multi-functional application scenarios

- Rapid emergency response: Building temporary roads, flood walls or shelters during disasters (such as in earthquake and flood rescue operations).

- Low-cost infrastructure: Suitable for reinforcing simple roads and canals in remote areas, reducing labor and logistics costs.

Special environment construction: Provide efficient solutions in areas such as steep slopes and narrow Spaces where traditional concrete is difficult to cover.

5. Economic advantage

- Low comprehensive cost: Although the unit price of materials is relatively high (about 200-500 yuan per square meter), by eliminating equipment rental, labor and maintenance costs, the overall cost can be reduced by 30% to 50%.

- Shorten the construction period: The project cycle is significantly compressed, reducing indirect losses caused by project delays (such as traffic control and downtime costs).

6. Superior technical performance

- High strength: The compressive strength reaches 20-50 mpa (equivalent to C20-C50 concrete), and the tensile strength is 10 times that of traditional concrete.

- Waterproof and anti-seepage: Surface waterproof coating + dense structure after hardening, suitable for anti-seepage projects such as water tanks and drainage systems.

- Fireproof and heat-resistant: Some models can withstand temperatures up to 1200℃, meeting the requirements of fire protection and industrial scenarios.

Comparison table of performance between New Cement blankets and traditional concrete

Performance Metric | Concrete Canvas Properties | Traditional Concrete Properties |

Curing Time | Hardens within 24 hours (thickness ≤50mm) | Requires 7–28 days of standard curing |

Construction Setup | 2-person crew for installation (no heavy machinery needed) | Requires mixing plant, pump trucks, and 5+ workers |

Terrain Adaptability | Supports ±180° bending (slopes, curves, complex terrain) | Only suitable for flat surfaces (tolerance ≤5mm/m²) |

Environmental Impact | CO₂ emissions ≤50kg/m³ (92% reduction vs. traditional) | Standard emissions ≥600kg/m³ |

Emergency Response | Ready-to-use (prefabricated rolls, no on-site mixing) | 6–8 hours of material prep (incl. transport and mixing) |

Specifications

| Test Item | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test Standard | Remarks |

| Length (M) | 10-50 M | / | |||

| Width (M) | 1-3 M | / | |||

| Thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm / | / | |||

| Compressive Strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T 17671-2021 | |

| Flexural Strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

| Flexural Strength Retention After Freeze-Thaw (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | Freeze-thaw cycles: 50-200 (indicators vary accordingly) |

| Water Quality Requirements | Tap water | Tap water、Seawater | Tap water、Seawater、Wastewater | / | |

| Construction Temperature | Above 0°C | Above -5°C | Above -5°C | / | |

| Fire Resistance | B1 | GB 8624-2012 | |||

| Hazardous Substance Leaching Test | Limit (mg/L) | GB 5085.3-2007 | |||

| Copper (Total Cu)(mg/L) | ≤100 | ||||

| Zinc (Total Zn)(mg/L) | ≤100 | ||||

| Cadmium (Total Cd)(mg/L) | ≤1 | ||||

| Lead (Total Pb)(mg/L) | ≤5 | ||||

| Chromium (Total Cr)(mg/L) | ≤15 | ||||

| Nickel (Total Ni) | ≤5 | ||||

| Arsenic (Total As) | ≤5 | ||||

Application field:

1. Water conservancy and agricultural engineering

Channel seepage prevention: It replaces traditional concrete lining, reduces seepage losses, and is suitable for irrigation channels and drainage ditches.

Water storage tanks/cellars: Rapidly build low-cost water storage facilities in arid areas to solve the problem of agricultural water use.

River bank protection: It prevents water flow erosion, protects the soil along the riverbank, is eco-friendly and convenient for construction.

2. Transportation infrastructure

Slope protection: Reinforcement of highway and railway slopes to prevent rainwater erosion and landslides (can be laid in accordance with steep slope curved surfaces).

Temporary roads: Temporary road surfaces for heavy vehicles in mining areas, forest areas, etc., with a load-bearing capacity of over 50 tons.

Tunnel lining: As an initial support layer, it quickly seals the rock surface to prevent collapse (it needs to be used in conjunction with anchor rods).

3. Industrial and Municipal Engineering

Factory floor: A corrosion-resistant and anti-seepage workshop floor, suitable for special environments such as chemical plants and slaughterhouses.

Pipeline wrapping: Anti-corrosion protective layer for underground pipelines to prevent erosion by soil acids and alkalis.

Landfill: As a seepage prevention liner, it prevents the leakage of pollutants and is more puncture-resistant than traditional HDPE membranes.

4. Ecological restoration and environmental protection projects

Mine greening: Cover exposed mine pits, solidify the surface soil, and provide a foundation for vegetation restoration.

Desert sand fixation: Laying grid-like cement blankets to fix mobile sand dunes and assist in afforestation.

Coastal protection: Replace traditional stone revetment, reduce ecological damage and prevent tidal erosion.

5. Architecture and Landscape Engineering

Temporary building foundation: The ground hardening of temporary venues such as exhibitions and events can be quickly dismantled and recycled.

Irregular structures: Rapid prototyping of garden landscapes such as sculpture bases and curved flower beds.

Roof waterproofing: Lightweight roof anti-seepage layer, especially suitable for roofs with large slopes and complex shapes.

6. Construction in special environments

In high-cold regions: It can still be watered and hardened (with the addition of antifreeze) in an environment of -30℃, solving the problem of traditional concrete winter construction.

Narrow Spaces: Rapid lining in confined Spaces such as subway shafts and underground pipe galleries without the need for large equipment.

Marine environment: Salt-resistant models are used for the repair of port fenders and breakwaters, and are resistant to seawater corrosion.

7. Emergency disaster relief and temporary projects

Flood control and rescue: Rapidly lay temporary embankments and seal breaches (such as river breaches and landslides), and form flood resistance barriers within 2 hours.

Disaster rescue: After earthquakes and typhoons, temporary roads are built and the ground of shelters is hardened to ensure the smoothness of rescue routes.

Emergency repair: Reinforcement of bridge foundations and rapid repair of collapsed sections to prevent traffic disruptions.

8. Military and security engineering

Field fortifications: Quickly build shelters, command post floors or explosion-proof walls, and harden within 1 hour to resist light weapon attacks.

Border defense facilities: Laying patrol roads or the foundations of outposts in complex terrain along the border to adapt to environments such as plateaus and swamps.

Anti-terrorism roadblocks: Temporary concrete isolation belts are set up to block vehicle impacts and can be flexibly deployed.